Earlie A

Well-Known Member

Here's what I know about the AFR head. I checked them out at a trade show a couple of months ago and took one picture. The first picture shown below is the AFR head. The reason I took the picture is because of the short turn machining. The blue arrow points to the 'cliff' that was left after the valve job. The top of the cliff is a sharp corner. No way that head is flowing 260+ without work. I was quite shocked a company would take that to a trade show for show and tell.

The AFR head is a Speedmaster casting. To my knowledge there are two foundries in China repopping the SBM head, SM and ProMaxx. The ProMaxx head comes from the Steven Sun foundry. I don't know the name of the SM/AFR foundry. I suppose there could be a third, but where would their heads be sold? Would have to be in the States.

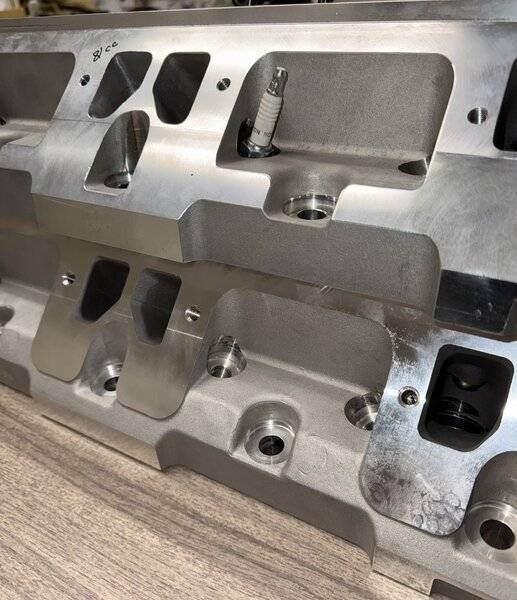

The second picture below shows the same view as the first picture, but this time a SM head. Note there is no cliff. The cliff on the AFR could just be a core shift issue. I've experienced core shift in both the SM and the ProMaxx heads in areas other than the short turn.

The third picture shows a ProMaxx head on top of a Speedmaster head. The differences between the two castings are obvious. The exhaust port face is the quickest way to differentiate between the two castings.

Again, the AFR head is a Speedmaster casting. A bare AFR head is $130 more than a SM head and I think the SM would flow better OOTB. I see no reason to buy a (bare) AFR head. Wait for Black Friday and save another 40% on the SM.

The AFR head is a Speedmaster casting. To my knowledge there are two foundries in China repopping the SBM head, SM and ProMaxx. The ProMaxx head comes from the Steven Sun foundry. I don't know the name of the SM/AFR foundry. I suppose there could be a third, but where would their heads be sold? Would have to be in the States.

The second picture below shows the same view as the first picture, but this time a SM head. Note there is no cliff. The cliff on the AFR could just be a core shift issue. I've experienced core shift in both the SM and the ProMaxx heads in areas other than the short turn.

The third picture shows a ProMaxx head on top of a Speedmaster head. The differences between the two castings are obvious. The exhaust port face is the quickest way to differentiate between the two castings.

Again, the AFR head is a Speedmaster casting. A bare AFR head is $130 more than a SM head and I think the SM would flow better OOTB. I see no reason to buy a (bare) AFR head. Wait for Black Friday and save another 40% on the SM.

Last edited: