As I've mentioned in other posts about the 360 I'm re-assembling, it's been a long time since I've done this, and even back when, I didn't do it a lot.

The engine came w/a hyd cam w/ purple paint on it and the lift checks at .508". I'm going to assume (uh,oh) that it's a 292-508 MP cam.

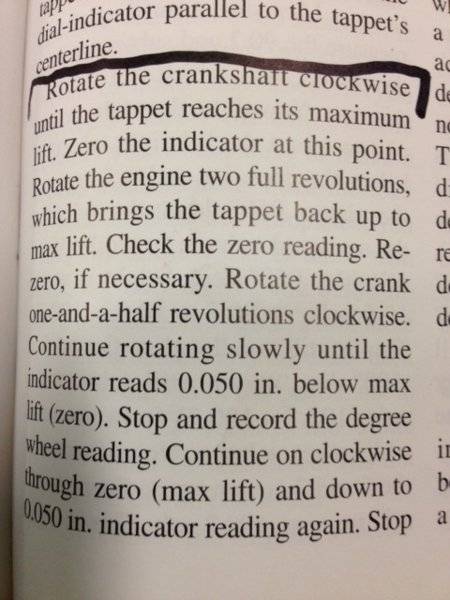

Searching on FABO, I am finding that there were 108 and a 112 versions. I just checked mine (twice) and I'm getting 98*. I used the method in the pictures, taken from Larry Shepard's book. Even if it's a 108, isn't that pretty far off? Am I missing something? It wouldn't be the first time...

The engine came w/a hyd cam w/ purple paint on it and the lift checks at .508". I'm going to assume (uh,oh) that it's a 292-508 MP cam.

Searching on FABO, I am finding that there were 108 and a 112 versions. I just checked mine (twice) and I'm getting 98*. I used the method in the pictures, taken from Larry Shepard's book. Even if it's a 108, isn't that pretty far off? Am I missing something? It wouldn't be the first time...