I would like to see another picture of the intake pushrod passageway. looks like mopar did a simple thing here like they did with the ta heads - machine the heads for the intake pushrods wider. or not machine them and let the customer do it

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Direct Connection ( Mullen LA ) heads

- Thread starter NCmtnDWELLER

- Start date

-

Yes correctAre you going to have to redrill that intake?

Anyone else think we may be about to see the quickest N/A 318 based build on forum?

yellow rose

Overnight Sensation

Anyone else think we may be about to see the quickest N/A 318 based build on forum?

Nope. The gods have spoken. It’s IMPOSSIBLE.

Case closed.

I doAnyone else think we may be about to see the quickest N/A 318 based build on forum?

Shane at CrowerAnyone else think we may be about to see the quickest N/A 318 based build on forum?

We help with that goal !

Correction: Stock stroke 318 build?

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,372

- Reaction score

- 8,933

No, not with those heads. They will fall short of even a basic W2. Better than a x or j head probably, but I'd wager a properly prepped set of W2s would kill these headsAnyone else think we may be about to see the quickest N/A 318 based build on forum?

Correction: Stock stroke 318 build?

Post 18. .090 over

Post 43. 333 ci

Yep, 4 inch bore by 3.31 stroke, 333 cubic inch (or 332.75). JE stocks a flat top SRP 4 inch bore piston (P/N SRP 345794S) with a 1.804 compression height for a 318, but they're flat tops. But that could easily be configured as a domed piston. But, it's going into a southeast gasser super stock competitor (1/8 mile) it will be running on 110 octane leaded with as close to 13:1 compression as is possible. And weight requirement is 9-1/2 lbs/cubic inch. So how quick it really can be is mandated by the rest of the competition. I don't know what kind of times they are running in super stock to be competitive (only the racers know their times, only the win lights come on at the finish), but I am suspecting it's in the 7 second range. But if anyone becomes dominant over the rest of the field by more than .15 second for more than one race they receive a "performance limiting plate" to put under the carburetor. So ultimately, that's going to have to be decided by who has a naturally aspirated 318 with a 3.31 inch stroke that shows us a time slip that's comparable or quicker....

Last edited:

Those are pretty neat. What is the point of having long valves, but not using the length for spring height? Seems to be a lot of stem above the retainers. Geometry correction?

The reason possibly for the long valves is so that they can run the Hemi Battleship Springs on that head.

That way they can rev that thing to the Moon.

Correction: Stock stroke 318 build?

It's not a stock stroke. Is it? Are we talkin about the same engine? I thought he was usin some kinda old school badass pro stock destroke crank.

I have the 3.20 crank but its preserved ! This is getting aIt's not a stock stroke. Is it? Are we talkin about the same engine? I thought he was usin some kinda old school badass pro stock destroke crank.

68 steel 340 crank .

Last edited by a moderator:

I have the 3.20 crank but its preserved ! This is getting a

68 steel 340 crank .

Ok gotchya. So it's a bored 318. That's gonna be badass.

Yes sir Lonely unwanted 318Ok gotchya. So it's a bored 318. That's gonna be badass.

90 over with partial fill !

One day those unwanted

Early model 318s might be desirable or sought after when the 340s & 360s are used up and im referring to LA platform not Magnum series.

Early model 318s might be desirable or sought after when the 340s & 360s are used up and im referring to LA platform not Magnum series.

Yes sir Lonely unwanted 318

90 over with partial fill !

View attachment 1715599977

View attachment 1715599978

Partial fill to the bottom of the freeze plugs?

Yes partial fillPartial fill to the bottom of the freeze plugs?

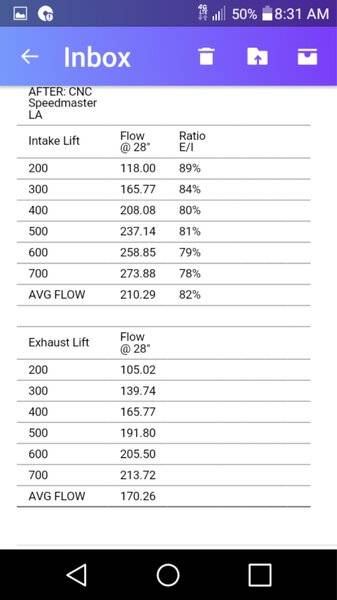

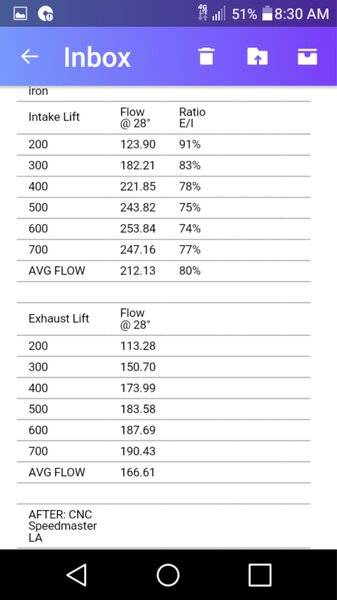

1BadColt sent initial flow tests against a set of ported speedmaster for comparison. The low lift flows look good. The W2 heads are indeed worth more up top after some extra machine cuts and porting. But still very impressive for the time. Plans are for some seat and guide work with 7mm stems and possibly larger valves if they prove beneficial and aren’t a risk for causing cracks.

Last edited:

MOPAROFFICIAL

Oogliboogli

Those are his flow numbers for the mullen heads? Disappointing, but thats standing in 2020 and looking back.1BadColt sent initial flow tests against a set of ported speedmaster for comparison. The low lift flows are amazing. The W2 heads are indeed worth more up top after some extra machine cuts and porting. But still very impressive for the time. Plans are for some seat and guide work with 7mm stems and possibly larger valves if they prove beneficial and aren’t a risk for causing cracks.

View attachment 1715637067 View attachment 1715637068

The numbers arent bad, just not big, though they carry to .600 . He probably worked to the exhaust to maintain the ratio, adhering to the rule of thumb at the time.

Last edited:

Garrett - add to section on head flows in

Small block section !

Someone comprised alot of info on this subject !

Small block section !

Someone comprised alot of info on this subject !

Garrett - add to section on head flows in

Small block section !

Someone comprised alot of info on this subject !

Flow numbers add and linked. I put it under the factory head section since they're based on a Chrysler casting.

Thank you - yes correct Oem 360 castingsFlow numbers add and linked. I put it under the factory head section since they're based on a Chrysler casting.

Thank You! I was having some difficulty locating the head flow chart.Flow numbers add and linked. I put it under the factory head section since they're based on a Chrysler casting.

After more calculations concerning the weight of the 66 valiant it's going into, the plan has reverted back to the original plan of 321.2 cubic inches to avoid having to use an excessive load of ballast.

-