adriver

Blazing Apostle

Last summer I replaced the pitman and a tie rod end on my daily.

I just guessed and eyeballed the toe hoping it was good.

But I noticed the car was hunting on the interstate.

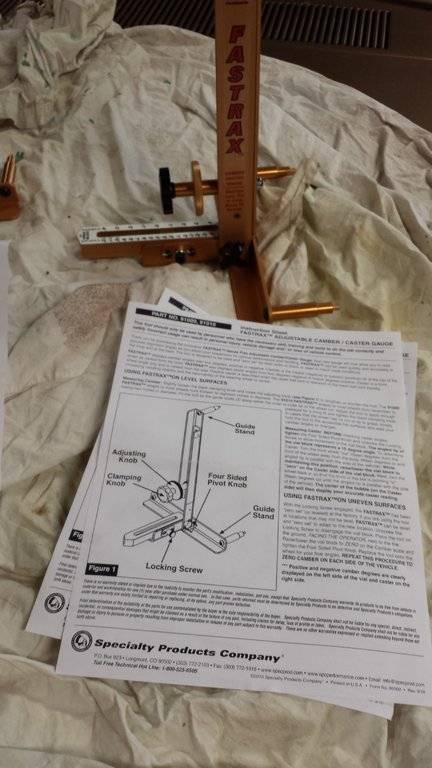

Since I will need to align front ends on two other vehicles I’m building, I bought these from Summit. Best price and free shipping. Summit supports our car club.

I also like "low tech". I trust spirit levels. And no batteries.

Sure enough my daily was a hair toe out.

I’ve set toe now to “factory” of 1/8 inch in .

Now the car and me are happy.

I’m generally impressed with the Fastrax and feel they are worth the money if you like DIY and not relying on other people.

But I’ve never really studied alignments before.. I’m posting so people with more experience than me can give some input.

Here’s what I can tell you about these.

I just guessed and eyeballed the toe hoping it was good.

But I noticed the car was hunting on the interstate.

Since I will need to align front ends on two other vehicles I’m building, I bought these from Summit. Best price and free shipping. Summit supports our car club.

I also like "low tech". I trust spirit levels. And no batteries.

Sure enough my daily was a hair toe out.

I’ve set toe now to “factory” of 1/8 inch in .

Now the car and me are happy.

I’m generally impressed with the Fastrax and feel they are worth the money if you like DIY and not relying on other people.

But I’ve never really studied alignments before.. I’m posting so people with more experience than me can give some input.

Here’s what I can tell you about these.

- They are not robust. Light weight and aluminum.

- They are easily knocked off the rims. Use caution working around them.

- I bought one for each side. It seemed to make the whole process easier. But they don’t clamp very hard on the rims (Number 2 above) So unless you have someone to hold the tape on the other side of the car you may have to do what I did and mark the floor and use a plumb level to see where the arms are to check toe.

- To set castor the instructions say to turn the wheel 15 degrees or make the pointer parallel to the side of the car. I’m thinking how much one turns the wheels will make a difference on what will show up as castor in an alignment. I think this is because the castor reading is a factor of how much “change” the tool sees when the wheels are turned. I’ve seen videos that specify a different amount to turn the wheels to measuring castor with similar tools.. I don’t know what would be right otherwise.

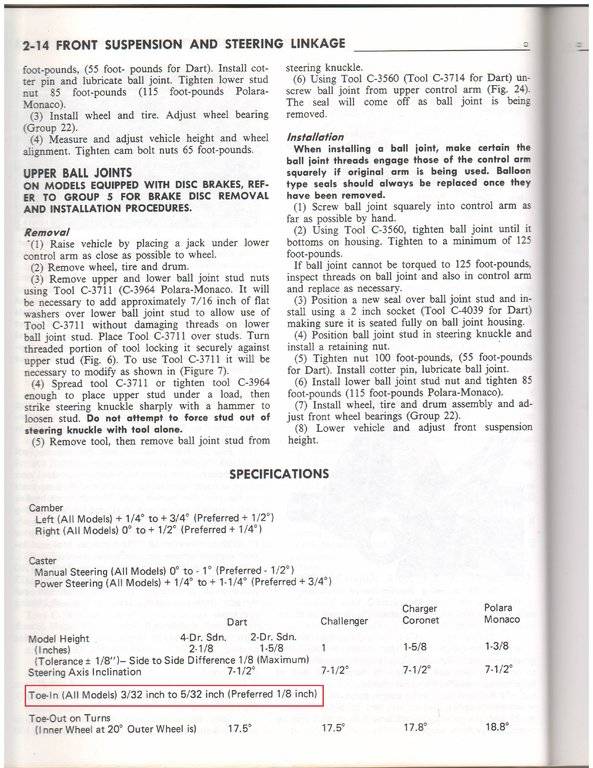

- All the alignment numbers in the factory manual seems to be in degrees except toe. I don’t understand two things about this. (1) IF toe is given in degrees, I’m thinking it makes NO difference how big a wheel is. Degrees off from center for the tire to the car would stay constant. (2) But by giving toe in inches ACROSS the car lines, it seems there would be some “error” due to different tire sizes between car lines. It would compound the error if bigger tires were used. This is what I did not know for sure about my car. The car has 15 inch tires now. Bigger than any A body came with. If we are given toe in inches it seem it would make a difference how big the tire is or where you measure.

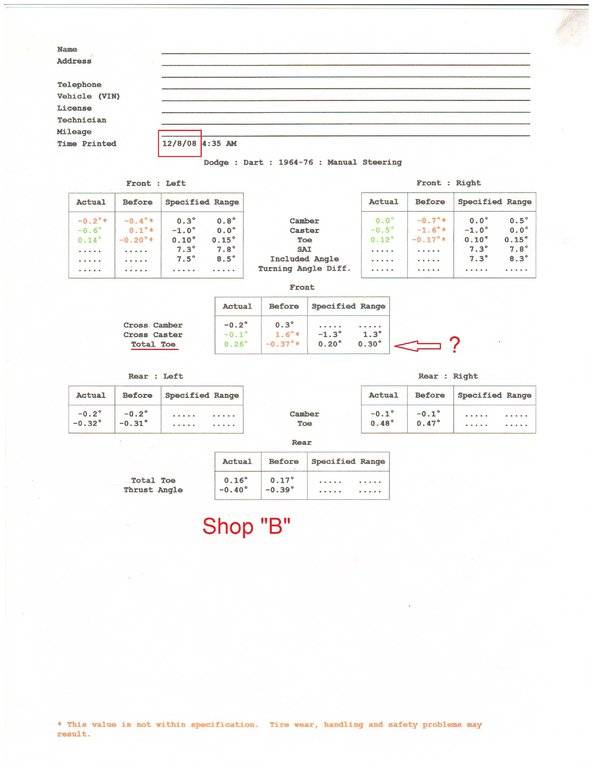

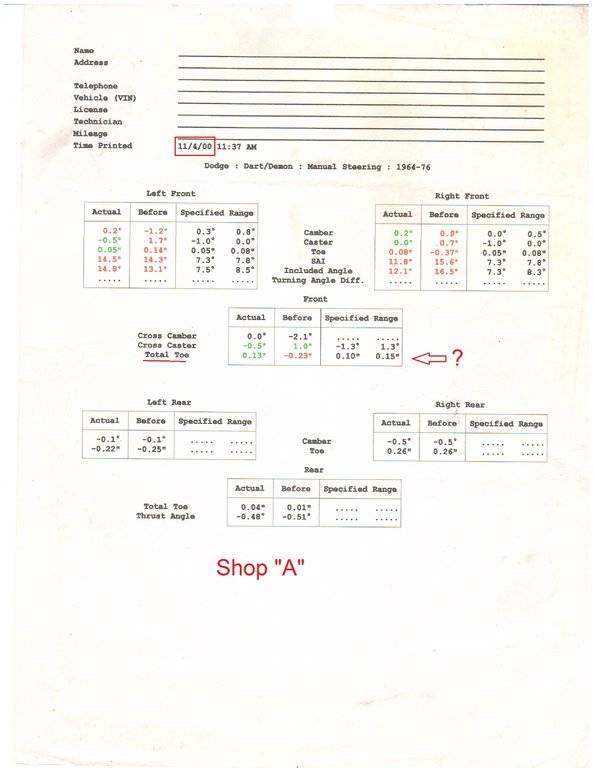

- Pictured are two alignment sheets from two different shops a few years apart. Why is “specified range” for total toe different? It’s in degrees as well. So, as I’ve noted in 5 above I think this would be a “constant” for any vehicle in that group.

Last edited: