rapidtransitric

LX/LC platform a body swap pioneer

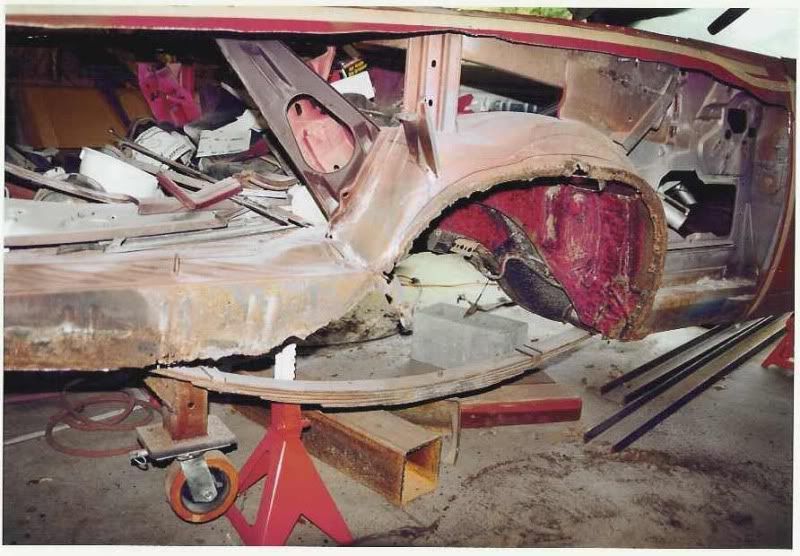

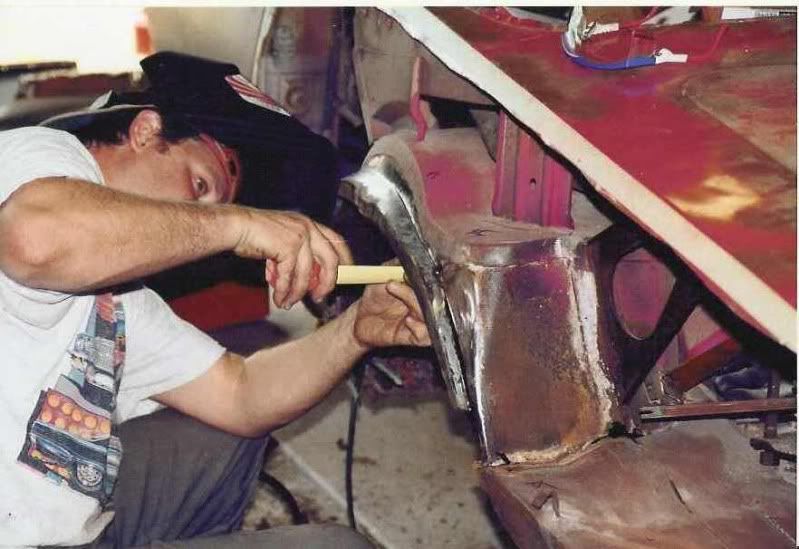

the wheelhouse caps will have to be rebuilt but i will do this after i get the inner and outers in. i was able to use what was left of the inner as a pattern for the new inner. i used a white marker to trace out the form and then cut it down with an air saw. then i popped in my holes for welding.