You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How often do you drain your air compressor?

- Thread starter Chuter

- Start date

-

Inertia

Well-Known Member

Yeah, I kinda pooched it there. Definitely need to get back to it and add more pipe above the valves, I just blow them out more often for the time being. But the temperature drop across the tubes is surprising.

Mine is same sorta thing only back and forth across the side of my barn, all tubes slope down, 1 drain .

- Joined

- Apr 16, 2009

- Messages

- 4,198

- Reaction score

- 5,997

This is an air dryer.

Whats wrong with using copper? I have been using it for 25 years and have never had an issue with it.

In my new shop we ran everything in pex then used copper for all the drop downs.

I personaly would never use PVC but I have seen alot of people doing it.

Scody21

Just send it

Nothing is wrong with copper, other than the cost. **** we are running 500 feet of PVC at 120 psi in my brothers new shop off that Atlas Cooper I posted earlier in this thread… His old shop had 40+ year old CPVC running at 125 psi. There were a few blow outs the last few years… lolView attachment 1716193198

This is an air dryer.

Whats wrong with using copper? I have been using it for 25 years and have never had an issue with it.

In my new shop we ran everything in pex then used copper for all the drop downs.

I personaly would never use PVC but I have seen alot of people doing it.

- Joined

- Apr 16, 2009

- Messages

- 4,198

- Reaction score

- 5,997

I drain mine whenever I think about it, definitely more in summer.

Usually the first time I get a spurt of water out of a tool...... I keep my tank full of air and shut the valve right at the tank outlet. Id love to find a drier to put in the line.

Usually the first time I get a spurt of water out of a tool...... I keep my tank full of air and shut the valve right at the tank outlet. Id love to find a drier to put in the line.

mcodecuda

Senior Member

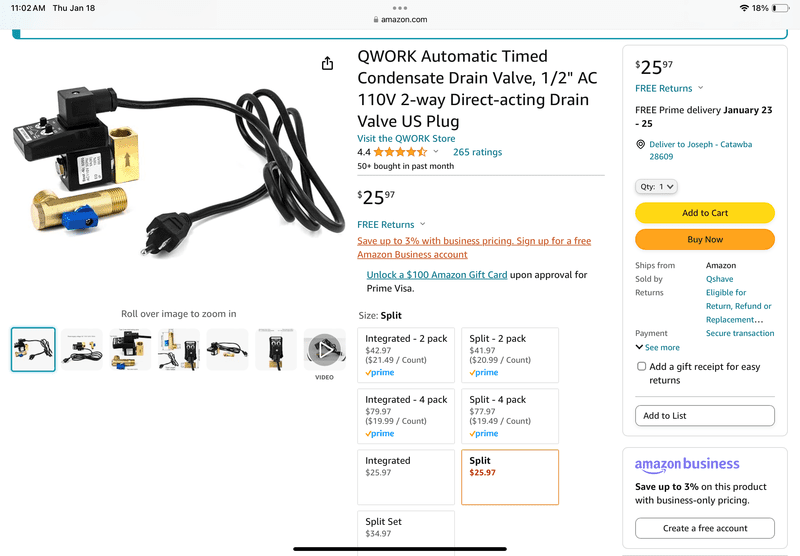

You guys put a curse on me. This morning my automatic drain valve stayed on for a few minutes rather than 30 seconds. It was quite old so I went and ordered a new one this morning.

Get to know how hot and humid the ambient air in your shop is. The hotter and more humid your ambient air is, the more you need to drain your tank.

Last edited:

I installed a 1/4 turn ball valve at the drain to make draining easier, and I drain the tank at the end of every day and leave it open until next use. Lots of different opinions here, but that's what I've always been taught as best practice. Those automatic drains are a neat idea, though.

I'm getting ready to install that exact unit. Is there any reason it can't be installed between the compressor and tank?No one's mentioned an air dryer. My work threw out a perfectly good 115-volt air dryer. Now I just need a shop againI know it just treats the air after the tank. I like the drain on the timer idea though.

Ingersoll Rand D25IN, Non-Cycling Refrigerated Air Dryer, 15 CFM, 1-Phase 115V

- Joined

- Apr 16, 2009

- Messages

- 4,198

- Reaction score

- 5,997

Post 55 is pictures of a homemade air drier installed between the pump and the tank.I installed a 1/4 turn ball valve at the drain to make draining easier, and I drain the tank at the end of every day and leave it open until next use. Lots of different opinions here, but that's what I've always been taught as best practice. Those automatic drains are a neat idea, though.

I'm getting ready to install that exact unit. Is there any reason it can't be installed between the compressor and tank?

If the hot air is dumped into the tank before the drier, then the air becomes ambient in the tank and the water falls out in the tank.

After neglecting my 60gal & acquiring pin holes in the bottom. which I fixed. Now draining is my new religion, installed 1/4" ball valve attached to poly tubing that goes out the wall vent. I find that draining after use is not enough. After use it takes a while for all the moisture to end up in the bottom of the tank. So sometimes it's necessary to Crack the valve when I walk by.

Chris1974

Active Member

I work in the construction world and we use compressors all the time we drain ours every day but most guys do not. I have drained other guys stuff and they are half full of water and green slime which will not only rust the tank but trash your air tools. My uncle worked for a trucking company that had a big three phase compressor in the shop and it exploded one day as he was walking by and almost killed him this is a serious topic they rust from the inside out.

Newbomb Turk

Well-Known Member

I work in the construction world and we use compressors all the time we drain ours every day but most guys do not. I have drained other guys stuff and they are half full of water and green slime which will not only rust the tank but trash your air tools. My uncle worked for a trucking company that had a big three phase compressor in the shop and it exploded one day as he was walking by and almost killed him this is a serious topic they rust from the inside out.

Damn. That’s scary.

Inertia

Well-Known Member

Do you guys give the pressure relief valve a twist now and then.

Tanks shouldnt be blowing-up with a functioning relief valve .

Tanks shouldnt be blowing-up with a functioning relief valve .

Last edited:

mcodecuda

Senior Member

The issue here is a tank exploding due to rust. The relief valve won’t help you if the compromised tank explodes at 95psi and the relief valve has a pop off of 150.Do you guys give the pressure relief valve a twist now and then.

Tanks shouldnt be blowing-up with a functioning relief valve .

mcodecuda

Senior Member

I jumped the gun here. My wife told me that it was the compressor cycling that morning and not the drain valve so the problem was that there was no problem.You guys put a curse on me. This morning my automatic drain valve stayed on for a few minutes rather than 30 seconds. It was quite old so I went and ordered a new one this morning.

View attachment 1716194102

Dale Davies

Well-Known Member

I worked for a company years ago that built a new heavy equipement shop. There was a ddouble entry door so cold air did not get in when you came in or went out. They put a large compressor on the top of the vestibule area with a loop in the piping about 4' up to trap water so it did not get into the air lines. The pipe was 2" to accomodate a bunch of us using impact wrenches. After a while I noticed that the compressor cut in quickly after starting to use an impact. I mmemmentioned this to the boss a few times and that I was sure the compressor tank was filling with condensed water. His reply each time was that there was no water as the loop caught it.Be honest now. I'm planning to build a new shop in the spring, and plan to get a bigger (noisier) air compressor. In my old shop, I had a 110 v. unit mounted on a stand. When I left for the night, I'd shut off the compressor, and reach under neath and open the drain valve. If I put the new one outside, I don't see myself being as diligent at draining it.

Friday of a long weekend I climbed up and opened the compressor drain. Tuesday morning we came in and all the drywall from the ceiling was in a soggy heap on the floor. Of course I got called into the office and asked about that. I just replied that he said there was no water. First job that day for me was to plumb a drain line down to easy elbow level so the tank could be drained every Friday.

For home use, depends on how much you use the compressor. Every Friday or Sunday night should work fine as it would be the end of the week for working in the garage. Make the drain easily accessable.

A loop does prevent the water getting into your air lines.

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,066

- Reaction score

- 4,053

Mine gets drained for five seconds every forty five minutes via an automatic drain valve. From the valve there is a piece of 1/4” copper tube ran through the wall to the outside.

Unless you change the oil in the compressor often I wouldn’t put it outside. My brother put his outside under a shed, the condensation in the oil would freeze and lock the compressor up. He moved it inside after the first winter.

Unless you change the oil in the compressor often I wouldn’t put it outside. My brother put his outside under a shed, the condensation in the oil would freeze and lock the compressor up. He moved it inside after the first winter.

- Joined

- Apr 16, 2009

- Messages

- 4,198

- Reaction score

- 5,997

A loop like the one I and a few others posted with traps and automatic drains damn sure does keep water from getting in the airlines Sir.I worked for a company years ago that built a new heavy equipement shop. There was a ddouble entry door so cold air did not get in when you came in or went out. They put a large compressor on the top of the vestibule area with a loop in the piping about 4' up to trap water so it did not get into the air lines. The pipe was 2" to accomodate a bunch of us using impact wrenches. After a while I noticed that the compressor cut in quickly after starting to use an impact. I mmemmentioned this to the boss a few times and that I was sure the compressor tank was filling with condensed water. His reply each time was that there was no water as the loop caught it.

Friday of a long weekend I climbed up and opened the compressor drain. Tuesday morning we came in and all the drywall from the ceiling was in a soggy heap on the floor. Of course I got called into the office and asked about that. I just replied that he said there was no water. First job that day for me was to plumb a drain line down to easy elbow level so the tank could be drained every Friday.

For home use, depends on how much you use the compressor. Every Friday or Sunday night should work fine as it would be the end of the week for working in the garage. Make the drain easily accessable.

A loop does prevent the water getting into your air lines.

Hot air into cold atmosphere equals condensation. Thats how refrigerated driers work and your compressor is working as one.Mine gets drained for five seconds every forty five minutes via an automatic drain valve. From the valve there is a piece of 1/4” copper tube ran through the wall to the outside.

Unless you change the oil in the compressor often I wouldn’t put it outside. My brother put his outside under a shed, the condensation in the oil would freeze and lock the compressor up. He moved it inside after the first winter.

You are right.

It is amazing how many here do not understand this concept.

It is proven.

I bought a brand new compressor for my shop 25 years ago and it came with an automatic drain valve. I used that compressor the whole time I had the shop and then sold it for almost what I paid for it. The compressor looked brand new and still ran great. The automatic drain valve was one reason the compressor lasted so long. Other reason was that I changed the oil and the air filter every year. It also helped that my compressor was inside a heated building so it never sucked in cold air or got damp.

Kendog 170

Let the boy go !

I don't see why not. I haven't got that far with it yet.I'm getting ready to install that exact unit. Is there any reason it can't be installed between the compressor and tank?

Chuter

Member

I appreciate everybody's input on this. I've picked up some good ideas to choose from!

A simple incadecent trouble light will put off enough heat to keep everything from freezing. I have to put one in my little outside compressor building.Mine gets drained for five seconds every forty five minutes via an automatic drain valve. From the valve there is a piece of 1/4” copper tube ran through the wall to the outside.

Unless you change the oil in the compressor often I wouldn’t put it outside. My brother put his outside under a shed, the condensation in the oil would freeze and lock the compressor up. He moved it inside after the first winter.

I drain my 80 gallon tanks before startup especially if I am going to blast or paint something. All of my tanks have a 3/8" pipe with manual operation ball type on the bottom drain valve

set up on each tank as I run multiple 80 gallon tanks in series for sheer volume. Manual operation valves either show you your drain port is open or clogged.....NO Guessing! You should never wait

very long especially if you live in a high humidity prone area of the world........ Some old craftsman (Sears) tanks do not have a bottom drain valve but do have blocked off ports on top of the tank......This type of situation calls for a quill drain system which can drain a tank (90-95%) even sitting in the upright position by pressurization of the tank.

A air tank not drained 1/2 filled with a liquid level can be very dangerous and can explode as the pressure wants to go somewhere and we all know water is a solid and does not compress.

set up on each tank as I run multiple 80 gallon tanks in series for sheer volume. Manual operation valves either show you your drain port is open or clogged.....NO Guessing! You should never wait

very long especially if you live in a high humidity prone area of the world........ Some old craftsman (Sears) tanks do not have a bottom drain valve but do have blocked off ports on top of the tank......This type of situation calls for a quill drain system which can drain a tank (90-95%) even sitting in the upright position by pressurization of the tank.

A air tank not drained 1/2 filled with a liquid level can be very dangerous and can explode as the pressure wants to go somewhere and we all know water is a solid and does not compress.

-