Tell you what unless your a serious racer you do not need all the bells and whistles for maybe 1/10 of a second. Biggest thing is get the curve right for YOUR motor.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Info on FBO ecu unit

- Thread starter Cuda 1964

- Start date

-

I tried one. It made my tachometer needle bounce around. I only installed it because it had a rev limiter.The one I installed recently has the revv limiter built in. I like that feature!

I have Dakota Digital gauges. Apparently, these two don't co-exist well. I even put a diode in the negative coil wire and it didn't help.

Yup and you can do that with a single point distributor!Tell you what unless your a serious racer you do not need all the bells and whistles for maybe 1/10 of a second. Biggest thing is get the curve right for YOUR motor.

Totally agree Rob. I like good points actually. For what 95% of us that drive 500 miles a year they will last 20 years.

So true its worth double posting!Biggest thing is get the curve right for YOUR motor.

Look at the race results and mpg cars obtained with the mighty power of points. With a correct curve and good engine design the spark to get a flame kernal to allow combustion doesn't need to be some super duper fireworks show.

and I've posted this before but I'll do it again. For racing at higher rpm the right curve for an electronic ignition has to take into account the slew rate. Long before internet my coworker who had been running stock eliminator had learned this the hard way when he removed the secondary spring from the Direct Connection tach drive distributor.

Tuner described the same lesson here except it was with a GM.

"A-B-A-B it was faster with the GM dual-points distributor, even though the spark energy was higher with the electronic, a GM Magna-Pulse, and the electronic had the same “curve” except for the retard after the “total” was reached at 2500. Jenkins book “The Small Block Chevrolet Racing Engine” details the high-RPM curve and explains his reasoning"

Last edited:

I know my 408 W2 ran like a dog when my "specialty curved to my combo" distributor was installed. My old setup was 22 initial, 32 total, all in by 2600.

The "tailored to my combo" 18 inital, 32 total, all in by 3500 was absolutely lazy. Felt like I'd lost 75 hp. I agree about the importance of the curve.

The "tailored to my combo" 18 inital, 32 total, all in by 3500 was absolutely lazy. Felt like I'd lost 75 hp. I agree about the importance of the curve.

BillGrissom

Well-Known Member

If an HEI module, you shouldn't need the ballast resistor, and better with an e-core coil. Do they suggest that? If upgrading an earlier engine with points ignition, why would anyone change to the Mopar ECU wiring, unless using the actual Mopar ECU? That would be clumsy wiring to the 5-pin connector and none of the ballast resistors would be needed. For HEI, easier and cheaper to use the GM 8-pin module (1985-95), GM coil, and cable which connects them. TrailBeast here used to sell a kit, or grab parts cheap at the junkyard. I use it on my 1960's Mopars.

I would like that, too. I've communicated with her before on Facebook and she's always been very responsive.I don't know the inner workings, but they are now digital to my understanding. I've linked this post to the new FBO owner in the hopes she responds and enlightens the group.

Hi Dave , good post . Do you know amplitude of GM pickup at some rpm and mopar stock pickup at some rpm ?quite amusing BUT

that top picture is of the guts of a jaguar I6 or V12 lucas igntion unit not an FBO . presume accidental attachment due to big HEI bit in middle of small icon of picture

Its a lucas AB14 unit with a radio interferance supressor (capacitor) and a zener diode in the top right to clamp back emf to 350 volts the white bit is just an insulated connection for all the wires held down with a plastic rivet. there aint nowt special in there

these used genuine GM and delco HEI modules which could only put up with 350V back emf off the primary hence the zener diode protection.

the lower picture is of an FBO unit.

there is no relationship between the two items. the FBO unit i dug all of the potting compound out off i think used descrete compontents and the usual big chunk of power transistor.

but never bothered to own one so don't know the full history, using HEI is a bit of a swizz if its true.

one is made from late 90s onwards by FBO

one made/assembled by lucas in the UK from the mid 70s to to mid 80s.

FBO uses magnetic pickup for timing only. the one i pulled apart in the 2000s was a robust version of the mopar set up designed for 12 volt use and no ballast with a low ohm primary coil other versions may exist.

AB14 and all HEI uses magnetic pickup for timing and magnetic pickup signal amplitude for dwell control. and a laminated iron core coil, 12 volt no ballast 0.5 or 0.6 ohm primary

a replacement AB14 is about $400 thats one expensive aluminium case.

i'm happy to repair burnt out AB14s for $250just send em to me... i'll pay the postage back

Dave

then we know dwell control rate from V/ rpm .

No need to reduce dwell until under ~ 3 k rpm to avoid coil overheat is why , and how they can eliminate ballast R So may do nothing till that area down ?

I thought chip in HEI looked at time between pulses not amplitude but either can work . But if amplitude , you might be screwed up with wring mopar vs GM pickup volts .

By the way HEI is a lot better conceptually than mopar , so those saying “ just a hei “ are leaving 1 k rpm on the table . Nothing wrong with early dual point either from old dodge v8 to 57 . more dwell , i think 55 back fits A block ( shaft length) .

Saw a dyno test where msd died on dyno 56 hemi , guy put dual point and ballast R he had on it exact same HP right to 6000. Nothing electronic to punt , 400 still in pocket too

Lord Sparky

Well-Known Member

No need to reduce dwell until under ~ 3 k rpm to avoid coil overheat is why , and how they can eliminate ballast R So may do nothing till that area down ?

Regardless, the standard coils were all designed assuming some type of control on the current allowed through.

Until, HEI, most companies used a resistor of some sort. The ballast resistor having the advantage of slightly lower resistance when cooled by more air flowing through the engine bay.

HEI used solid state electronics to control the current. @KitCarlson may have posted the specifics at some point in the past.

Regardless, the standard coils were all designed assuming some type of control on the current allowed through.

Until, HEI, most companies used a resistor of some sort. The ballast resistor having the advantage of slightly lower resistance when cooled by more air flowing through the engine bay.

HEI used solid state electronics to control the current. @KitCarlson may have posted the specifics at some point in the past.

Hi Dave , good post . Do you know amplitude of GM pickup at some rpm and mopar stock pickup at some rpm ?

then we know dwell control rate from V/ rpm .

No need to reduce dwell until under ~ 3 k rpm to avoid coil overheat is why , and how they can eliminate ballast R So may do nothing till that area down ?

I thought chip in HEI looked at time between pulses not amplitude but either can work . But if amplitude , you might be screwed up with wring mopar vs GM pickup volts .

By the way HEI is a lot better conceptually than mopar , so those saying “ just a hei “ are leaving 1 k rpm on the table . Nothing wrong with early dual point either from old dodge v8 to 57 . more dwell , i think 55 back fits A block ( shaft length) .

Saw a dyno test where msd died on dyno 56 hemi , guy put dual point and ballast R he had on it exact same HP right to 6000. Nothing electronic to punt , 400 still in pocket too

[/QUOTE]

This thread is probably the most complete in depth look into the workings of the factory ECU.

It also links to others.

www.forabodiesonly.com

www.forabodiesonly.com

then we know dwell control rate from V/ rpm .

No need to reduce dwell until under ~ 3 k rpm to avoid coil overheat is why , and how they can eliminate ballast R So may do nothing till that area down ?

I thought chip in HEI looked at time between pulses not amplitude but either can work . But if amplitude , you might be screwed up with wring mopar vs GM pickup volts .

By the way HEI is a lot better conceptually than mopar , so those saying “ just a hei “ are leaving 1 k rpm on the table . Nothing wrong with early dual point either from old dodge v8 to 57 . more dwell , i think 55 back fits A block ( shaft length) .

Saw a dyno test where msd died on dyno 56 hemi , guy put dual point and ballast R he had on it exact same HP right to 6000. Nothing electronic to punt , 400 still in pocket too

[/QUOTE]

This thread is probably the most complete in depth look into the workings of the factory ECU.

It also links to others.

1974 Brain Box saves the day.

Was heading out to a local car gathering a couple weeks ago, and a no start on my '76 Truck. Turns out the 1 year old replacement brain box failed. I had a well used 1974 5 pin brain box from my '74 Dart that I had replaced because all the goo on the back had melted out from the hot sun in...

www.forabodiesonly.com

www.forabodiesonly.com

Dave999

Well-Known Member

Hi Dave , good post . Do you know amplitude of GM pickup at some rpm and mopar stock pickup at some rpm ?

then we know dwell control rate from V/ rpm .

No need to reduce dwell until under ~ 3 k rpm to avoid coil overheat is why , and how they can eliminate ballast R So may do nothing till that area down ?

I thought chip in HEI looked at time between pulses not amplitude but either can work . But if amplitude , you might be screwed up with wring mopar vs GM pickup volts .

By the way HEI is a lot better conceptually than mopar , so those saying “ just a hei “ are leaving 1 k rpm on the table . Nothing wrong with early dual point either from old dodge v8 to 57 . more dwell , i think 55 back fits A block ( shaft length) .

Saw a dyno test where msd died on dyno 56 hemi , guy put dual point and ballast R he had on it exact same HP right to 6000. Nothing electronic to punt , 400 still in pocket too

I don't know the amplitude that the dwell control is triggerd, never found it and don't have the equipment to work it out....

i think it will be module specific, linked to original application, and it will be to do with the supporting components the manufacturer uses with the Motorola chip that is embedded in all of them. subtle changes to capacitors and resistors around that chip, allow the module to be matched to specific pickups and specific igition coils.

however the dwell control is used at low rpm not at high... you would assume the opposite

basically, due to HEI systems running a 0.6 ohm coil at 12-14.5 volts

at low rpm the coil would overheat so the HEI module reduces the dwell dramatically.

However due to running the coil at this voltage and its very low primary resistance

the total dwell time to get the coil up to max flux regardless is tiny in comparison to the time period between the necessary spark events to run a v8 at higher rpms

as RPM increases the peak of the reuluctor signal increases and dwell is extended until it reaches this maximum dwell figure which fits nicely with an rpm that is at redline or more on a v8.

so what you have is the exact reverse of all other igntions.

HEI has short dwell to protect coil at low rpm and maximum permissable dwell at High rpm

obvioulsy with everything else that has a coil that has a high resitance primary

the time to get it FULL is way way longer

and as the RPM increases the necessary dwell for a good spark is not possible because the necessary dwell time is longer than the time between each spark event,

anyway some good reading below

first link

A discussion of the benefits of HEI, some words on pickup coil and dwell control etc, and how to convert a lucas distributor...

second link

A comparison of CDI Vs MDI or magnetic igntion, such as HEI. Mainly all the bits about transistor zener clamped MDI

the HEI module has a modern interpretation of a transistor zener clamped set-up

basically in conclusion he says CDI and HEI are much the same spark power in more or less all cases applicable to road and affordable race engines

http://nebula.wsimg.com/5956cdbfbf7...E22DE049163134A29&disposition=0&alloworigin=1

http://nebula.wsimg.com/88a559cc1e6...E22DE049163134A29&disposition=0&alloworigin=1

i use a mopar pickup. all seems to work well to 6000 rpm

documents above hint at why some people seem to run into a problem at lower RPMs than that....

all to do with coil primary and secondary resistance

Dave

Last edited:

MadScientistMat

Well-Known Member

- Joined

- Mar 6, 2008

- Messages

- 694

- Reaction score

- 298

Keep in mind that the max permissable dwell at high RPM isn't very much. At 3000 RPM on a V8, you have 5 milliseconds between spark events. If you give the coil a millisecond to discharge, you have 4 milliseconds for it to fire. Keeping the same 1:4 ratio between discharging and dwell would drop that to 2 milliseconds at 6000 RPM.

Plug in the numbers for an MSD Blaster 2 coil and aim for a max current of 6 amps as a somewhat conservative safe level of current, and you'll find it needs to dwell for 4.9 ms to reach that much current. That 2 ms time at high RPM would only reach about 2.7 ms. At low RPM there is enough time that you would want to stop the charging at a point that limits current. The just isn't enough time to reach high levels of current at high RPM, so at that point any dwell control is aimed at managing the ratio of discharge time to dwell.

Plug in the numbers for an MSD Blaster 2 coil and aim for a max current of 6 amps as a somewhat conservative safe level of current, and you'll find it needs to dwell for 4.9 ms to reach that much current. That 2 ms time at high RPM would only reach about 2.7 ms. At low RPM there is enough time that you would want to stop the charging at a point that limits current. The just isn't enough time to reach high levels of current at high RPM, so at that point any dwell control is aimed at managing the ratio of discharge time to dwell.

KitCarlson

Well-Known Member

@Mattax

About HEI coil current limit. It works by turning off coil drive transistor when current exceeds set limit, and back on when current is under limit. Switching happens in fast repetive manner, such that resulting current is smoothly regulated. It takes only one small transistor, and a low value shunt resistor in coil drive emitter to ground connection. The small transistor collector pulls down the drive transistors base input signal, over ridding normal control. Resistance of shunt resistor is about 1/15 of ballast resistor, and drop of only 0.65V vs 6V with ballast, however drive transistor does dissipate additional energy, when in current limit.

Based on my ignition development work, with proper dwell control, current limit action only happens when cranking, and unstable low RPM below idle speed.

About HEI coil current limit. It works by turning off coil drive transistor when current exceeds set limit, and back on when current is under limit. Switching happens in fast repetive manner, such that resulting current is smoothly regulated. It takes only one small transistor, and a low value shunt resistor in coil drive emitter to ground connection. The small transistor collector pulls down the drive transistors base input signal, over ridding normal control. Resistance of shunt resistor is about 1/15 of ballast resistor, and drop of only 0.65V vs 6V with ballast, however drive transistor does dissipate additional energy, when in current limit.

Based on my ignition development work, with proper dwell control, current limit action only happens when cranking, and unstable low RPM below idle speed.

Dave999

Well-Known Member

looks like that is a dead link all i get is godaddy sign up page

Dave999

Well-Known Member

The MSD blaster 2 is a cannister style coilKeep in mind that the max permissable dwell at high RPM isn't very much. At 3000 RPM on a V8, you have 5 milliseconds between spark events. If you give the coil a millisecond to discharge, you have 4 milliseconds for it to fire. Keeping the same 1:4 ratio between discharging and dwell would drop that to 2 milliseconds at 6000 RPM.

Plug in the numbers for an MSD Blaster 2 coil and aim for a max current of 6 amps as a somewhat conservative safe level of current, and you'll find it needs to dwell for 4.9 ms to reach that much current. That 2 ms time at high RPM would only reach about 2.7 ms. At low RPM there is enough time that you would want to stop the charging at a point that limits current. The just isn't enough time to reach high levels of current at high RPM, so at that point any dwell control is aimed at managing the ratio of discharge time to dwell.

regardless of the turn ratio and the primary resistance I believe the configuration tends to result in less effective flux carrying by the core and a higher resistance in the secondary.

it won't discharge as quickly and more energy wasted heating up the coil

i.e for good reason the original HEI coil is a laminated core transformer style unit, open to the air and clamped by its core to a chunk of mounting bracket

i haven't looked very hard for turn ratios etc for this style of coil, so i could just be spouting BS

BUT I'm inclined to think best results can be had with the right type of coil, GM wouldn't have specified a new one if not necessary, tooling costs, new bracket that doesn't fit a standard coil mount, new connector, different capcitor, traning for the guys on the line all that stuff.

hence my quip about priamry and secondary resistance having an impact on rpm range

Basically i think if you pair a cannister coil with an HEI you get poorer performance in some cases

although the two links i provided talk about the bosch GT40 in good terms and it is a cannister style coil much like the MSD popular in Australia and europe but called different things

MSD do the 8226 which looks more like the right kinda thing

But id rather spend $20 + shipping on an ebay or rockauto filko for a chevy truck, or indeed $40 on the ford version mentioned in another thread, than £120 for the MSD kit

i loose therfore, by not having a big red coil pack sticking out when i pop the hood, but i'm happy if i get much the same spark from what looks like the remains of a broken microwave oven.

i can live with that, looks awful, but it works

Dave

Last edited:

TT5.9mag

Two atmospheres are better than one

@Dave999 I run the 8202 MSD canister coil with a hei module. I’ve worried about heating up the coil and after some miles I’ll grab the coil as a check and it’s cool to the touch. Is there a measurable amount of heat that is acceptable? Like “it’ll be fine at *** degrees but after that will burn up”?

Last edited:

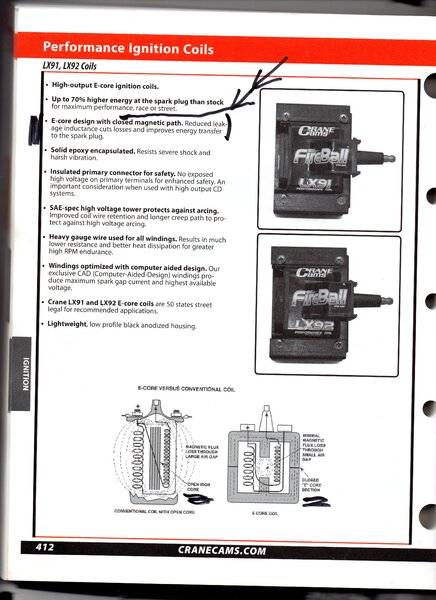

You certainly will be getting less spark energy out of the 8202, compared to an E core coil. You should use the 8207 [ or equivalent ] because it is an E core coil. E core coils cost more to make & there is a reason that car makers use them........

The heat in the spark [ the current ] is what ignites the mixture; the 8202 produces 140mA; the 8207 produces 300mA.

The 8202 is probably staying cool because the adaptive dwell of the HEI is working: dwell [ current on time & therefore coil heating ] is reduced at lower rpms.

See below why the E core is superior.

The heat in the spark [ the current ] is what ignites the mixture; the 8202 produces 140mA; the 8207 produces 300mA.

The 8202 is probably staying cool because the adaptive dwell of the HEI is working: dwell [ current on time & therefore coil heating ] is reduced at lower rpms.

See below why the E core is superior.

TT5.9mag

Two atmospheres are better than one

I ran a test in open air prior to sticking it in the car and spun the dist with a drill. Both the e core I had (2001 ram 5.9) and the 8202 seemed to produce the same spark to the naked eye. And both fired the plug easily to .080 gap, as wide as I tested. So I went with the one that was easier to mount.

TT5.9mag

Two atmospheres are better than one

I tend to agree with you. But this is a stock 318 so I’m not lighting off a cylinder dosed with methanol or anything. It runs much better and doesn’t kill coils. So I’m happy.I would be using the coil that provides the most spark energy, not the one that is easiest to mount.....

A spark in free air tells you nothing about the spark characteristics of that coil.

Plus, you don't have 12:1 compression. That's when you need a bunch more spark. The stock Mopar system is fine. Even in the upper compression ranges, just add a hotter ECU. Problem solved. I just don't have the hard on for the HEI a lot of guys do. It's just not necessary.I tend to agree with you. But this is a stock 318 so I’m not lighting off a cylinder dosed with methanol or anything. It runs much better and doesn’t kill coils. So I’m happy.

-