Well to say it cannot make power with low compression pisses all over the 73 340 and the 78 and 79 360 in the Lil Red express trucks. Those engines were far from slugs. Yall been readin WAY too many magazines and suckin the forum lollipops.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LA360 compression

- Thread starter Matt68

- Start date

-

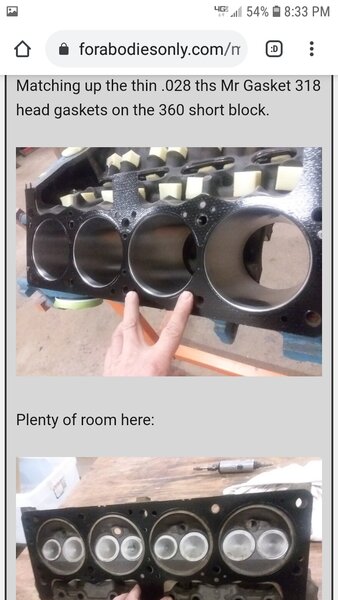

Here is your 360 short block:

Here is a .030 over 360 with stock height replacement pistons:

Is being assembled with stock J Heads, and new stock size 1.88/1.60 valves.

Have the option to install the heads with the .028 ths thin head gaskets to bump the compression a tad.

Also this build has the 340 cam and stock early 340 square bore intake manifold.

Going to run out just fine as is, and won't break the bank in the process.

☆☆☆☆☆

Here is a .030 over 360 with stock height replacement pistons:

Is being assembled with stock J Heads, and new stock size 1.88/1.60 valves.

Have the option to install the heads with the .028 ths thin head gaskets to bump the compression a tad.

Also this build has the 340 cam and stock early 340 square bore intake manifold.

Going to run out just fine as is, and won't break the bank in the process.

☆☆☆☆☆

☆☆☆☆☆

From what most say even the 10.5:1 340 was only 9.5:1 cause of tolerances, read a stock copy build/dyno of 375hp 440 magnum and they said factory pistons were way down the hole to, the cr was way bellow stated. Seem like many of these 60's engines were really never high cr to begin with wonder if Ford and Chev were similar.Well to say it cannot make power with low compression pisses all over the 73 340 and the 78 and 79 360 in the Lil Red express trucks. Those engines were far from slugs. Yall been readin WAY too many magazines and suckin the forum lollipops.

Dale Davies

Well-Known Member

IMHO, he does not want to finish the engine as is. Your car is at a full service shop, so they should be qualified to:Problem is, I have the car sitting at a full service shop and it has been for 3 weeks. They are waiting on the engine to be finished to install as they are pulling the 318 and also changing the rear diff. Lots going on and at this point I just need this 360 ready.

1: measure the deck height and show you the exact value.

2: they can install the intake manifold and accessories and get the engine installed.

3: I would take your short block and heads to them to finish.

IF the deck height is 0.100"+, I would be inclined to veify the stroke, piston CD and rod length. Stroke is easy once you install a degree wheel and use a piston stop to find true TDC. Rotate to BDC and measure from deck surface to the piston crown directly over the wrist pin. Then rotate to TDC and measure in the same place. The difference is the stroke.

Pull one rod and piston assembly out and measure the pin bore diameter in the piston and divide by 2. Measure from the top of the pin bore to the top of the piston crown. Add the 1/2 pin bore to get the piston CD. Now you can compare that to what the KB spec is for the piston.

Slant six run with an obscene piston below the deck surface which is definately not optimal.

The Stove Bolt Chevs were the same. You can mill 0.070"" off the deck to achieve zero deck and then 0.090" off the head to increase the CR and quench.

@QUINN FORBES Yeah, he showed me the calculator he used to estimate the compression. He just feels that .100 is too far below deck and I'm letting go of a lot of quench using this set up. He wants to stroke it, basically changing all the internals. That's a wasted brand new cam, crank, rods and pistons. He says I definitely want a roller cam if the car isn't driven daily, because that cam will get bone dry and ruin lifters. I don't want to argue with this guy as he is a professional (at engine rebuilds and prostock racing), and I'm sure he doesn't need my business as his shop was full of engines waiting for rebuilds and ones already rebuilt. He just doesnt want to finish it as is because he says I'll be pretty unhappy with the performance. He is Alan Prusiensky of Arc Racing Engines so he's a Mopar guy.

It is up to you if you want to go all out on this build. Don't be pushed into something you don't want or you can't afford.

Don't know what piston you are running, but if KB's as indicated and they

Absolutely correct.From what most say even the 10.5:1 340 was only 9.5:1 cause of tolerances, read a stock copy build/dyno of 375hp 440 magnum and they said factory pistons were way down the hole to, the cr was way bellow stated. Seem like many of these 60's engines were really never high cr to begin with wonder if Ford and Chev were similar.

One thing that I don't think has been mentioned is the rods. If a story was told about the pistons, then I would want to check if new rod bolts were used and rods rebuilt. This is likely why builder mentioned stroker- buy the rods and pistons and you are most of the way to the cost of a cast crank stroker bottom end. It

If you are interested I will make you a good deal on a all new stroker kit I have.

If you are interested I will make you a good deal on a all new stroker kit I have.

Matt68

Well-Known Member

@mgoblue9798 , sent you a pm.

There's no FRAKKIN WAY they are in the hole .100" or more. NO WAY. I just figured it on the United Engine web site and the KB107 sits .012" in the hole with the stock 9.6 block, 6.123 connecting rod and the KB107's 1.675" compression height. Something is WRONG somewhere. If the piston really is in the hole that much, it's NOT a KB107.

It's in the hole...

It's in the hole...

How is ya Karl?

Matt68

Well-Known Member

It's in the hole...

How is ya Karl?

Yeah Karl, really good to see you. Its been awhile. Miss your humor! By the way, one of my all time favorite movies.

Really? Dangit. I've watched it several times trying to feel it, but I just caint get into it.Yeah Karl, really good to see you. Its been awhile. Miss your humor! By the way, one of my all time favorite movies.

Really? Dangit. I've watched it several times trying to feel it, but I just caint get into it.

I remember great quotes like:

"Nice tie, Ty"

"This is your saliva line"

"What's a saliva line?"

(She licks his palm) "it shows how hot I can get you"

Carl is the best though!

"Cannonball, Cannonball"

"you can play 36 holes on it in the afternoon, take it home and just get stoned to the bejeezus-belt that night on this stuff."

I'll toss my2c in here as I just freshened up the 360LA last summer in my 74 Challenger. It's not high compression either, build thread here: 360 LA installing Promaxx Aluminum heads. The smaller closed chamber heads got it just over 9:1 using a stock thickness Felpro 1008 head gasket. It has .030 (dished stock pistons) that are .100 in the hole with a mild cam .480/.480 using 1.6 ratio rockers, and Promaxx 63cc aluminum heads topped with an air gap intake and Holley 625 & TTI shortys. It's not a dog... pulls my Challenger around town just fine. Unless you are chasing ET's at the track.. 400HP~400Ftlb torque is plenty fun. Run it as is and don't change a thing.

Matt68

Well-Known Member

Well, I've returned the Speedmaster 68CC Heads and I am just going with a rebuild of the late 80's swirl port 714 heads that were on my 318. Anyone know the combustion chamber size of a stock pair of 714's?

Dan the man

Well-Known Member

KB-107 pistons have a 1.675" CH. With a stock block they should be no more than 0.012" below the deck surface. Who ever figured a 0.100" is way off.@QUINN FORBES Yeah, he showed me the calculator he used to estimate the compression. He just feels that .100 is too far below deck and I'm letting go of a lot of quench using this set up. He wants to stroke it, basically changing all the internals. That's a wasted brand new cam, crank, rods and pistons. He says I definitely want a roller cam if the car isn't driven daily, because that cam will get bone dry and ruin lifters. I don't want to argue with this guy as he is a professional (at engine rebuilds and prostock racing), and I'm sure he doesn't need my business as his shop was full of engines waiting for rebuilds and ones already rebuilt. He just doesnt want to finish it as is because he says I'll be pretty unhappy with the performance. He is Alan Prusiensky of Arc Racing Engines so he's a Mopar guy.

Dan the man

Well-Known Member

I used the NGK compression calculator and with kb107 pistons 0.012" below the deck and 68cc heads,0.039" thick headgasket with pistons having 5cc valve reliefs and a 4.030" bore stock stroke, I got a compression ratio of 9.90:1. I don't know how your machine shop came up with 8.0:1ok engine builders. Here is my dilemma. I bought a Mabbco rebuilt 360 short block from a member. Some upgraded stuff like KB high compression flat top pistons, moly rings, 272 muscle cam (272/272 duration 454-454 lift) Cloyes HD timing chain and sprokets. .30 over bore. Got a nice brand new set of Speedmaster aluminum heads with 68cc combustion chambers.

Here's the problem; my engine is at a builders for finishing. Went by there yesterday and he said this engine will be an absolute dog as it sits now. He doubts it will make 8:1 compression. Yes, the pistons are below deck a little, but he says I am losing a lot of quench with them. He suggests new pistons, rods, roller cam and new crank. That's an expensive prospect, considering what I already have in the motor. Also, this guy is a very well known builder with a great reputation and is well known in the racing circuit. His shop is incredible and he rebuilds engines for a living, and has many many great reviews. He does not even want to assemble the rest because he says he knows I will be disappointed.

What to do? Will this motor be a dog like he says? I don't know that I have the scratch to have him tear down this motor and upgrade it to a stroker.

TIA.

View attachment 1716094189

Read the thread and you will know.I used the NGK compression calculator and with kb107 pistons 0.012" below the deck and 68cc heads,0.039" thick headgasket with pistons having 5cc valve reliefs and a 4.030" bore stock stroke, I got a compression ratio of 9.90:1. I don't know how your machine shop came up with 8.0:1

Matt68

Well-Known Member

@Dan the man , because it's been decided that they are not KB107's like I was told. They might be KB's, but they are a flat top piston and have no reliefs like the 107's. They are definitely sitting about .100 below deck. The above pic of the orange block is mine.I used the NGK compression calculator and with kb107 pistons 0.012" below the deck and 68cc heads,0.039" thick headgasket with pistons having 5cc valve reliefs and a 4.030" bore stock stroke, I got a compression ratio of 9.90:1. I don't know how your machine shop came up with 8.0:1

Dan the man

Well-Known Member

It's a bummer that you was miss lead about the pistons. 8.25:1-8 5:1 compression motor can be made to run good. Good luck with your project@Dan the man , because it's been decided that they are not KB107's like I was told. They might be KB's, but they are a flat top piston and have no reliefs like the 107's. They are definitely sitting about .100 below deck. The above pic of the orange block is mine.

My money says they are Silvolite stock replacement pistons.@Dan the man , because it's been decided that they are not KB107's like I was told. They might be KB's, but they are a flat top piston and have no reliefs like the 107's. They are definitely sitting about .100 below deck. The above pic of the orange block is mine.

Why would you return the heads?Well, I've returned the Speedmaster 68CC Heads and I am just going with a rebuild of the late 80's swirl port 714 heads that were on my 318. Anyone know the combustion chamber size of a stock pair of 714's?

QUINN FORBES

Greendemon

-