Almost like dating in the 90s.....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

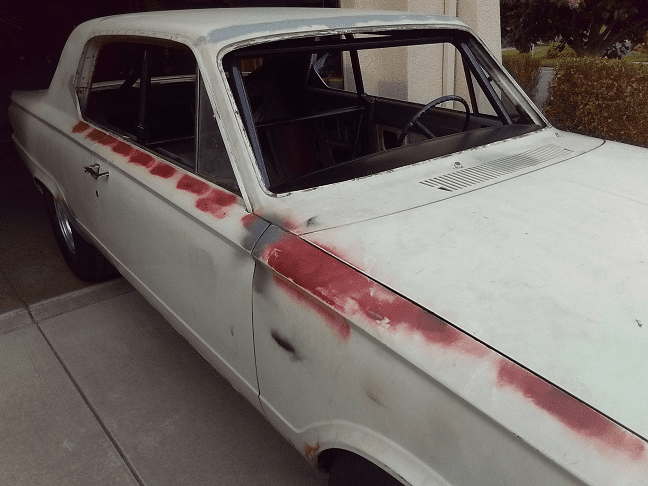

Mopowers' 66 Dart Build

- Thread starter mopowers

- Start date

-

mopowers

Well-Known Member

I've been gathering up all of interior parts that need to be re-done and calling around to see what a local shop would charge to install a headliner for me. I've received quotes from $350-$450, all the way up to $750-$950 for just the labor. I've heard they are a total pain in the ***, but I may just suck it up and give it a shot myself.

mopowers

Well-Known Member

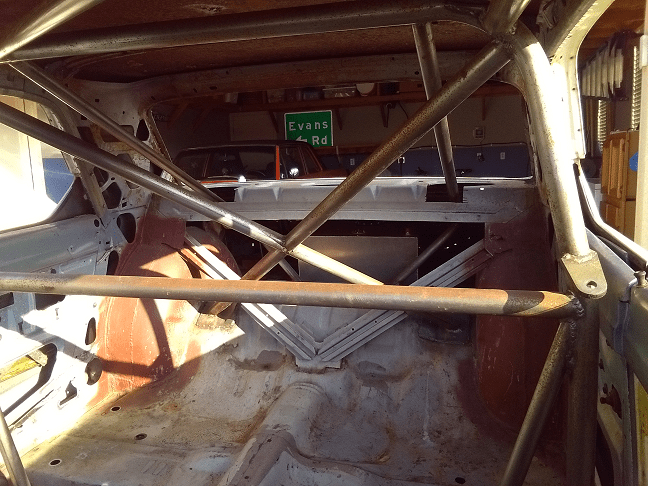

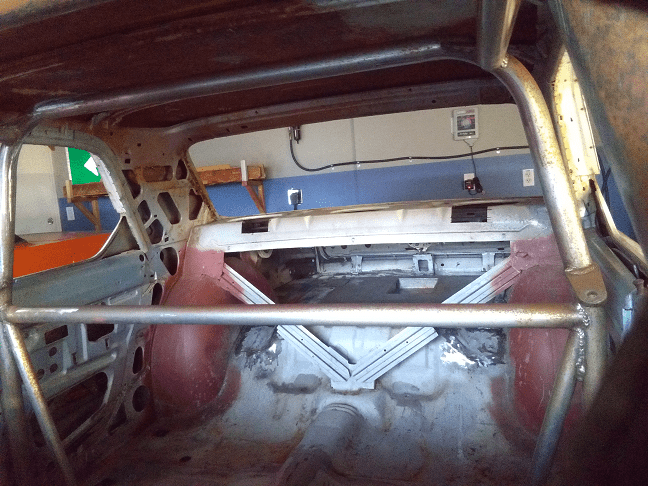

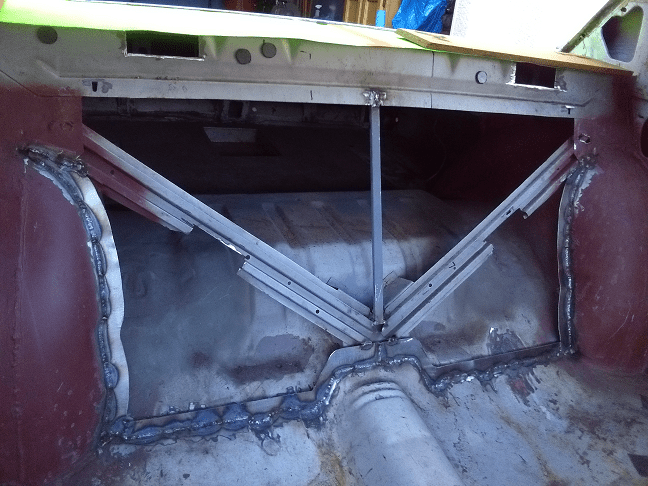

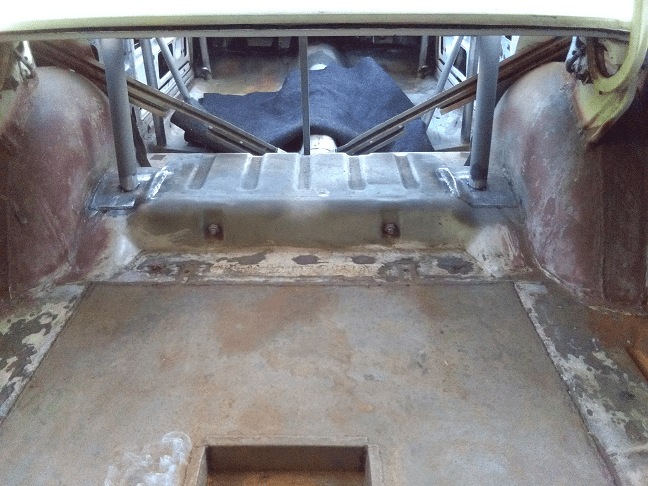

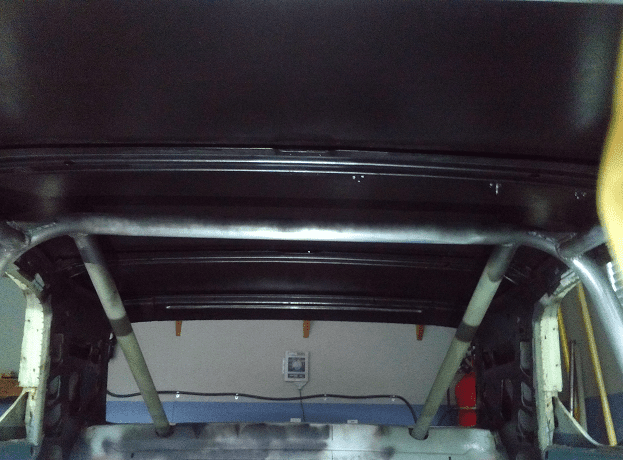

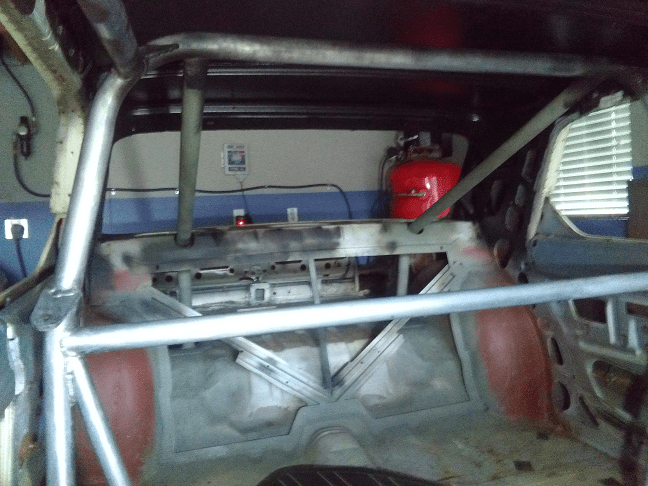

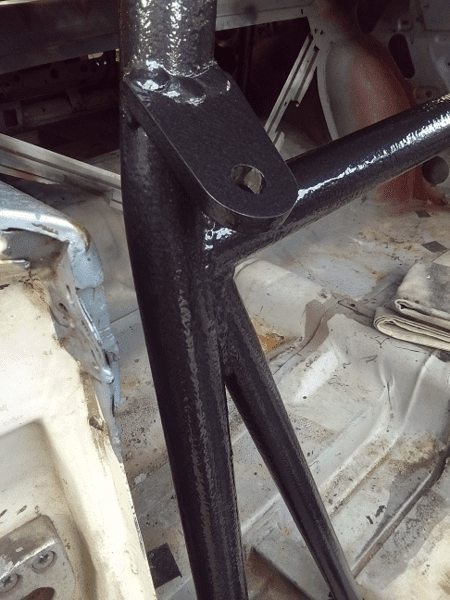

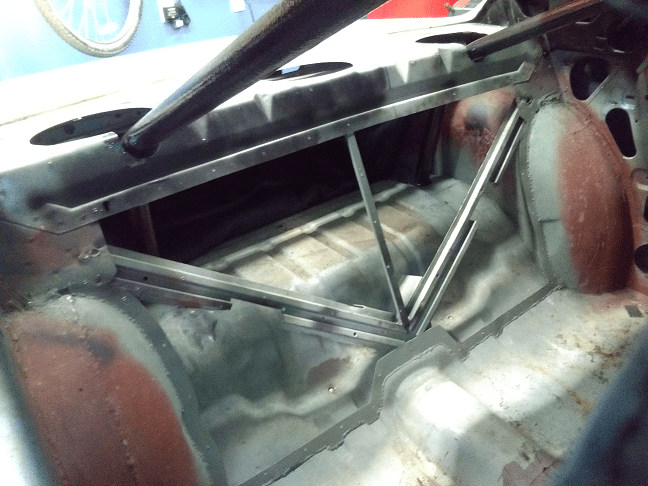

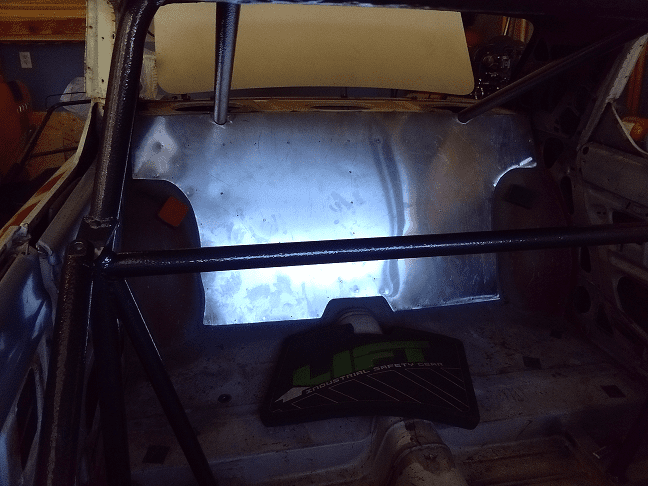

I guess it's time to update this. Up next was working on de-rusting the interior and re-doing the rear cage bars.

Before:

After some reciprocating saw and grinder work:

Before:

After some reciprocating saw and grinder work:

mopowers

Well-Known Member

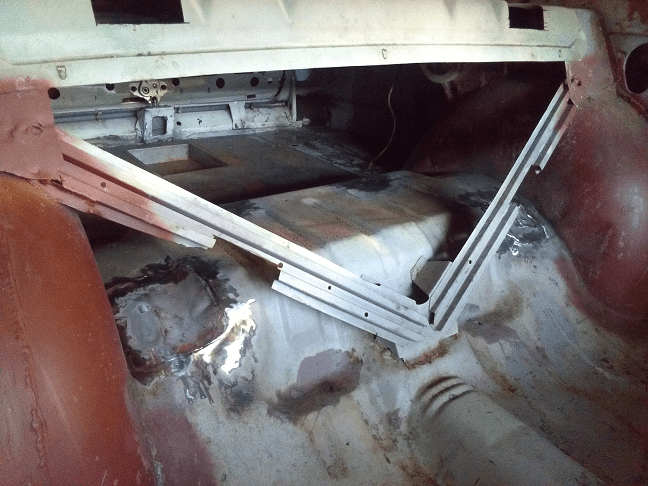

Next up was patching the package tray notches that were cut out.

mopowers

Well-Known Member

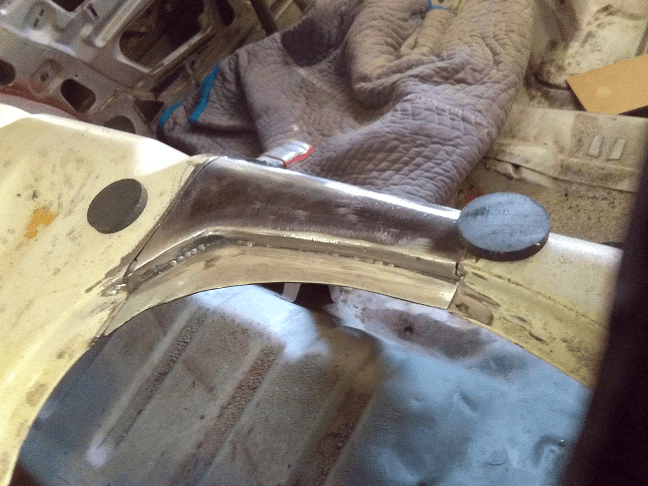

Then I decided to weld on a flange where I'll be attaching the rear bulkhead with rivets:

Last edited:

mopowers

Well-Known Member

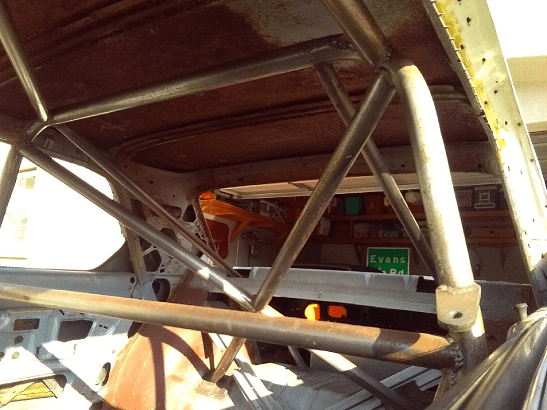

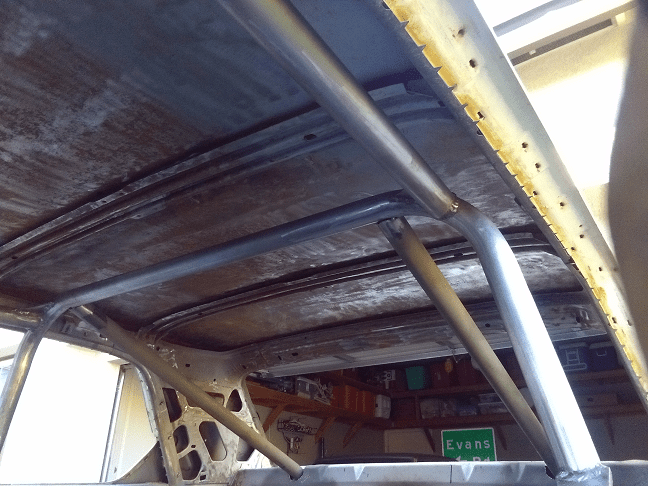

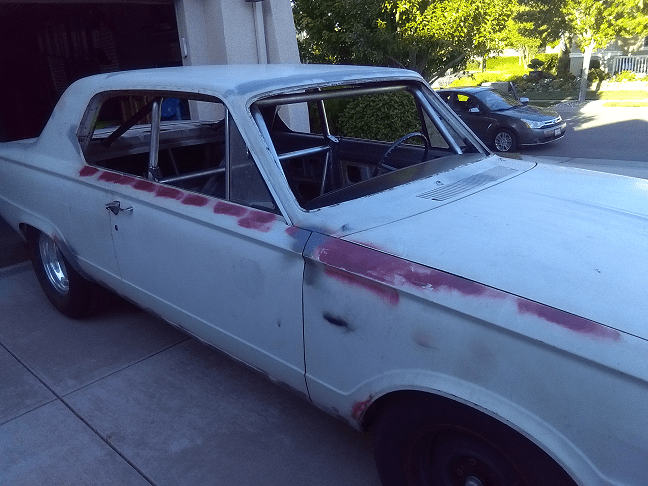

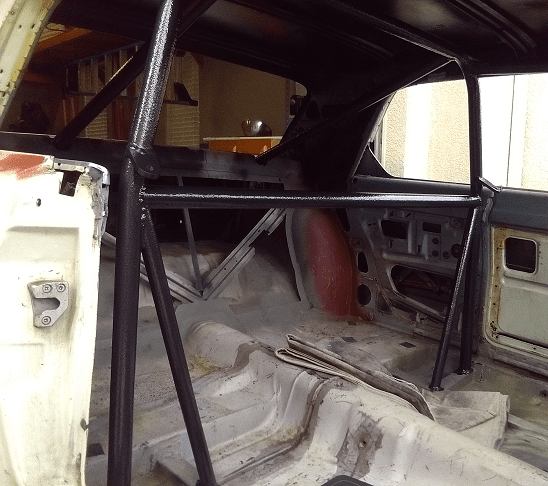

New bent rear bars are mocked up and fit very well. Also started going to town on the surface rust on the roof panel. What a pain in the *** that was.

Before:

After:

After some Ospho rust treatment and finish welding the new rear bars.

After a coat of Zero-Rust:

Before:

After:

After some Ospho rust treatment and finish welding the new rear bars.

After a coat of Zero-Rust:

Last edited:

mopowers

Well-Known Member

It's getting there. Little by little. It does feel good to have all of the fabrication done and the cage cleaned up and ready for paint.

mopowers

Well-Known Member

mopowers

Well-Known Member

Though I've been tied up in other things lately and haven't had a chance to get much done on the '66, I was able to paint the cage over the weekend. Next up is rebuilding the window mechanisms and making some interior panels.

mopowers

Well-Known Member

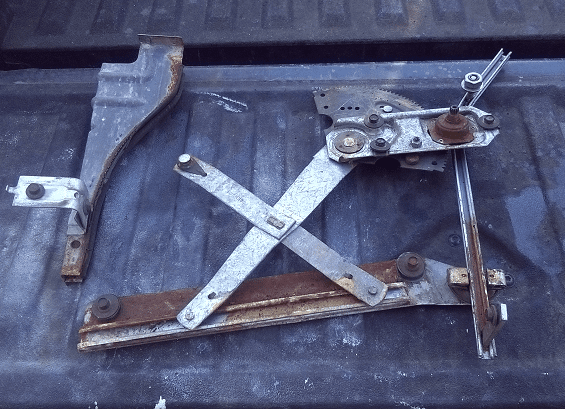

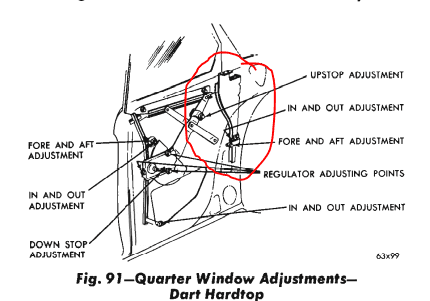

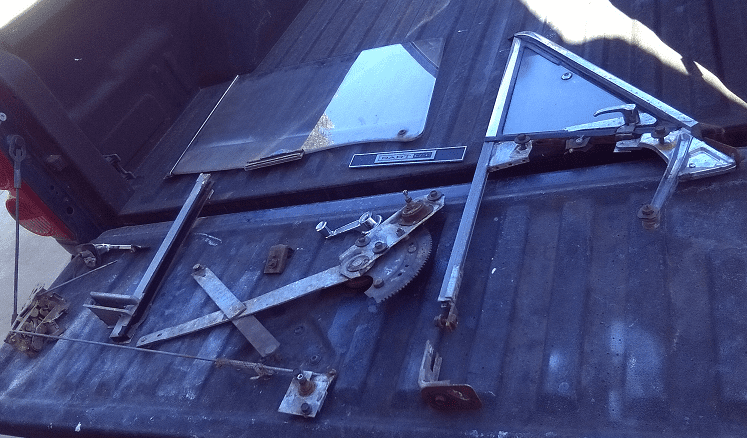

Got the quarter glass out to clean up the mechanisms and re-install. For the sake of my sanity, I'll only be doing one side at a time.

A huge thanks to @Jim Kueneman for the excellent write-ups on his builds. A 66 Dart is slightly different than the 63, but his write-up on his 63 Dart convertible helped a lot with the order of operations. His build threads are GREAT resources in general.

A huge thanks to @Jim Kueneman for the excellent write-ups on his builds. A 66 Dart is slightly different than the 63, but his write-up on his 63 Dart convertible helped a lot with the order of operations. His build threads are GREAT resources in general.

mopowers

Well-Known Member

Does anyone know where I can find these pieces new? This is the rear guide channel for the quarter window for a 66 Dart HT. The guide felts are similar to the horizontal window felts (cat whiskers), but they're stapled on. I couldn't find them on DMT's website.

Any ideas?

This is where this piece goes:

Any ideas?

This is where this piece goes:

mopowers

Well-Known Member

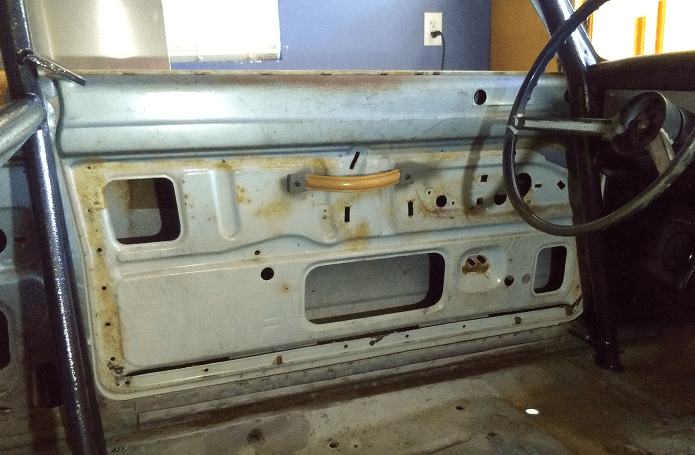

Got the driver's door gutted this afternoon. It amazes me how automotive engineers always seem to find a way to put 10 lbs of **** in a 5 lb bag. I'm not looking forward to putting all this back together, that's for sure. At least everything looks to be in great shape. It just needs to be cleaned up and re-greased. Speaking of, what do you all use to grease your window tracks and regulators?

I wish my fab skills were 1/10 as good. Nice work!

mopowers

Well-Known Member

I wish my fab skills were 1/10 as good. Nice work!

Thanks, but like most people around here, I just learn as I go. Just wish I had more time to dedicate to this car. You know the drill though.

Yeah well, some people learn better than others. lolThanks, but like most people around here, I just learn as I go. Just wish I had more time to dedicate to this car. You know the drill though.

mopowers

Well-Known Member

I got the window mechanisms all cleaned up and painted and figured it'd be a good time to do some tin work. I ended up using .035" aluminum. I apologize for the crappy photos. I'll take better ones once it's all finished up. I still need to finish install them with rivets and sealer around the edges.

And one of my redneck sheet metal break.

And one of my redneck sheet metal break.

mopowers

Well-Known Member

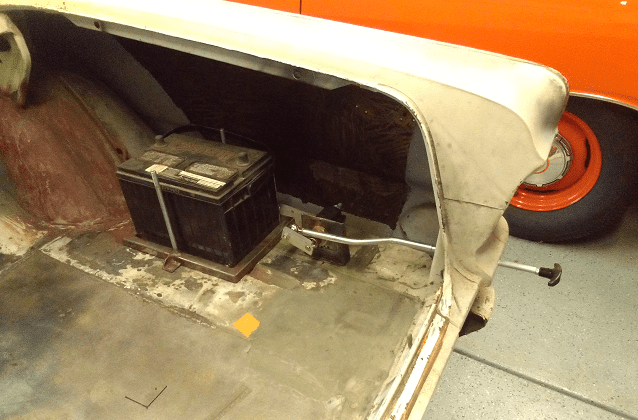

Not much to look at, but I've been focused on getting the trunk buttoned up and ready for paint so I can mount the firewall and package tray for good and paint the trunk, door jams and start putting this ***** back together. Today, I got the kill switch and battery tray located and mounted up. I also got some of the flaking factory quarter panel sound deadener scraped off. I just have to finish wiping the residual sound deadener off; Goo Gone works great for that.

rmchrgr

Skate And Destroy

Nice job on both the switch and firewall, looks similar to what I did.

mopowers

Well-Known Member

I certainly will. I just have to finish cleaning up the trunk before riveting on the package tray and firewall for good.Nice job on both the switch and firewall, looks similar to what I did.

I may also replace my current 20gal fuel cell with a 15gal model. The 20 gallon cell is obnoxiously large.

Do you have any photos of your switch/battery install? Or trunk photos in general? I'm trying to figure out a logical place to mount a CD relay, Ford solenoid, circuit breaker, etc.

rmchrgr

Skate And Destroy

I certainly will. I just have to finish cleaning up the trunk before riveting on the package tray and firewall for good.

I may also replace my current 20gal fuel cell with a 15gal model. The 20 gallon cell is obnoxiously large.

Do you have any photos of your switch/battery install? Or trunk photos in general? I'm trying to figure out a logical place to mount a CD relay, Ford solenoid, circuit breaker, etc.

I use a 4 pole Moroso disconnect for use with an alternator, saves a lot of hassle since you eliminate having to use a CD solenoid in the alternator output line to prevent keeping power alive to the dash after the switch is thrown. Most garden-variety disconnect switches aren't rated to have much current going through the secondary poles hence the need for a high-amp rated CD solenoid.

It's not in this picture but the starter relay will be attached to a little bracket that will bolt to the back of the wheel well where the jack goes. I actually am using a starter solenoid from a Jeep application since it has a provision for a neutral safety switch though it looks almost identical to the Ford one. There's a small ground lug on the back of the Jeep one that the NSS attaches to. That also helps to clean up the wiring. It's a Standard Parts one but I forget the number.

The lever is 3/8" aluminum bar stock. I heated it up with a torch and bent around a makeshift jig in my vise. One end was tapped for the handle stud on the outside and the other for the rod end by the switch.

This was a mockup I did before painting the trunk.

I also really wanted to avoid drilling a hole in my nice, pristine rear panel so I used this little space between the license plate and bumper for the lever to go through. It's not visible but the lever is supported by a little bracket I welded to the floor right behind the panel. The lever will get trimmed so it does not stick out too far. It only requires an inch or two of linear travel to activate the switch.

First coat of color. Note the switch bracket painted to match.

This is what the disconnect switch used to look like. The photo is during mockup so it was not complete. Plus, it actually is wired backwards here, the Ford solenoid power 'in' is on the left. Note that it's a regular "Ford" starter solenoid (bottom) without the extra ground lug. The CD solenoid is mounted above it. The switch was outside under the bumper.

With this setup I was using a "normal" 4 pole cutoff switch. The secondary lugs on that switch were not rated to handle a lot of current which is why you need the high-amp CD solenoid. This was NOT easy to figure out because the solenoids needed to be wired in such a way that one would power the other while being controlled by both the key and the switch downstream when necessary. It worked but I never liked it, too complex.

Hope that all Makes sense?

mopowers

Well-Known Member

I use a 4 pole Moroso disconnect for use with an alternator, saves a lot of hassle since you eliminate having to use a CD solenoid in the alternator output line to prevent keeping power alive to the dash after the switch is thrown. Most garden-variety disconnect switches aren't rated to have much current going through the secondary poles hence the need for a high-amp rated CD solenoid.

It's not in this picture but the starter relay will be attached to a little bracket that will bolt to the back of the wheel well where the jack goes. I actually am using a starter solenoid from a Jeep application since it has a provision for a neutral safety switch though it looks almost identical to the Ford one. There's a small ground lug on the back of the Jeep one that the NSS attaches to. That also helps to clean up the wiring. It's a Standard Parts one but I forget the number.

The lever is 3/8" aluminum bar stock. I heated it up with a torch and bent around a makeshift jig in my vise. One end was tapped for the handle stud on the outside and the other for the rod end by the switch.

This was a mockup I did before painting the trunk.

View attachment 1715993821

I also really wanted to avoid drilling a hole in my nice, pristine rear panel so I used this little space between the license plate and bumper for the lever to go through. It's not visible but the lever is supported by a little bracket I welded to the floor right behind the panel. The lever will get trimmed so it does not stick out too far. It only requires an inch or two of linear travel to activate the switch.

View attachment 1715993822

First coat of color. Note the switch bracket painted to match.

This is what the disconnect switch used to look like. The photo is during mockup so it was not complete. Plus, it actually is wired backwards here, the Ford solenoid power 'in' is on the left. Note that it's a regular "Ford" starter solenoid (bottom) without the extra ground lug. The CD solenoid is mounted above it. The switch was outside under the bumper.

With this setup I was using a "normal" 4 pole cutoff switch. The secondary lugs on that switch were not rated to handle a lot of current which is why you need the high-amp CD solenoid. This was NOT easy to figure out because the solenoids needed to be wired in such a way that one would power the other while being controlled by both the key and the switch downstream when necessary. It worked but I never liked it, too complex.

View attachment 1715993827

Hope that all Makes sense?

View attachment 1715993819

I like it! Nice install. I like the battery box too. I may end up using one instead of the tray I made a while back. I like that it doubles as a mounting surface for some of the electrical components.

rmchrgr

Skate And Destroy

Thanks. Frankly, I probably wouldn’t mount the solenoids to the box as it’s supposed to be sealed. It was never raced like that so I can’t say whether it would have passed tech or not. I‘m still using the same battery box so the plan is to plug/cover the holes. Just something to think about, probably be OK either way as long as it’s a sanitary job and does not invite extra scrutiny.I like it! Nice install. I like the battery box too. I may end up using one instead of the tray I made a while back. I like that it doubles as a mounting surface for some of the electrical components.

mopowers

Well-Known Member

I could be wrong, but I believe the battery only needs to be in a sealed box if you're not running a rear firewall that meets the minimum thickness specs.Thanks. Frankly, I probably wouldn’t mount the solenoids to the box as it’s supposed to be sealed. It was never raced like that so I can’t say whether it would have passed tech or not. I‘m still using the same battery box so the plan is to plug/cover the holes. Just something to think about, probably be OK either way as long as it’s a sanitary job and does not invite extra scrutiny.

That actually brings up another question I need to do some research on. Is there a need to use a sealed battery box vented to outside the car if using a firewall? I vaguely remember reading that there's a potential for corrosion issues in the trunk area if you leave the battery open. Is there any truth to that statement?? I'd imagine if you're using a sealed battery like an Optima, it's a moot point.

rmchrgr

Skate And Destroy

"In lieu of rear firewall, battery may be located in a sealed .024" steel, .032" aluminum or NHRA accepted poly box. If sealed box is used in lieu of rear firewall, box may not be used to secure battery and must be vented to outside of body".

"Relocated batteries must be fastened to frame or frame structure with a min. of two 3/8" dia. bolts."

"Metal battery hold-down straps mandatory. Strapping tape prohibited."

Can't answer about the battery causing corrosion - the battery in my car has always lived in a box, be it aluminum or one of those blue plastic ones made by Moroso. If you don't want to deal with a sealed box I'd at least use a tray at a minimum.

"Relocated batteries must be fastened to frame or frame structure with a min. of two 3/8" dia. bolts."

"Metal battery hold-down straps mandatory. Strapping tape prohibited."

Can't answer about the battery causing corrosion - the battery in my car has always lived in a box, be it aluminum or one of those blue plastic ones made by Moroso. If you don't want to deal with a sealed box I'd at least use a tray at a minimum.

-