I agree with this.I'm usually focused on getting all the underneath stuff done first...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Dart Swinger Project!

- Thread starter Dartfreak75

- Start date

-

Dartfreak75, nice to see you are moving forward with the Dart project. I guessing the work place didn't close their doors after the last mishap, good. I am sure the primer you use will be just fine, prep work as you know is the foundation to a great paint job. Are you still going with the crimson color you pick out earlier?

Dartfreak75

Restore it, Dont part it!

Yea I am getting all my primer and clear from spi i was gonna get my base from the restoration shop place but Barry at spi gave me a number to call I'm gonna check their prices first. I will call tomorrow.Whatever you do make sure all your paints are compatible...

Are you going to put the motor in with the K frame? Are you going to rebuild the suspension on the K frame?

I'm not removing the kframe I'm gonna set the motor and trans in from the top. I am gonna put all my suspension back in before the motor except for the tie rod and torsion bars because of the header room issue. After I get all that in I will slide on the tbars and reconnect the tierod ends. As far of the underneath stuff I have some more welding to do. I want to go ahead and do my frame connections. And I have all new brake lines and gas lines and all that but I dont want to put them in until the paint is done. I wonder how much it would rust if I went ahead and started sanding and blasting it to bare metal in three weeks time?

Dartfreak75

Restore it, Dont part it!

Yea we are back up and running another guy damn near lost a finger the very next day. Ocha came in and assessed the place and all the did was take our latters!! No joke! I'm not even kidding. I looked at my boss and said he wasnt on the latter when he got his hand ripped off?? My boss just shook his head.Dartfreak75, nice to see you are moving forward with the Dart project. I guessing the work place didn't close their doors after the last mishap, good. I am sure the primer you use will be just fine, prep work as you know is the foundation to a great paint job. Are you still going with the crimson color you pick out earlier?

Anyway yes I'm going with fk5 burnt orange It's kinda rusty redish in the dark but burst orange in the sun.

j par

Well-hung Member

Just get as much as you can. Again I would start on the bottom stuff...Yea I am getting all my primer and clear from spi i was gonna get my base from the restoration shop place but Barry at spi gave me a number to call I'm gonna check their prices first. I will call tomorrow.

I'm not removing the kframe I'm gonna set the motor and trans in from the top. I am gonna put all my suspension back in before the motor except for the tie rod and torsion bars because of the header room issue. After I get all that in I will slide on the tbars and reconnect the tierod ends. As far of the underneath stuff I have some more welding to do. I want to go ahead and do my frame connections. And I have all new brake lines and gas lines and all that but I dont want to put them in until the paint is done. I wonder how much it would rust if I went ahead and started sanding and blasting it to bare metal in three weeks time?

Dartfreak75

Restore it, Dont part it!

What other bottom stuff do you think I need?? From the doors up everything underneath is gonna be brand new. The rear end I'm not really gonna mess with yet because I have the 8.8 I'm gonna put in it.Just get as much as you can. Again I would start on the bottom stuff...

I could go ahead and drop the tank and clean it and check the sending unit. The exhaust is new. The rear shocks and springs getting replaced with the 8.8 so no point in doing that yet. So frame connections and gas tank. Anything else I'm forgetting?

how is all the frame work.... in the back where the leaf shackles mount?What other bottom stuff do you think I need?? From the doors up everything underneath is gonna be brand new. The rear end I'm not really gonna mess with yet because I have the 8.8 I'm gonna put in it.

I could go ahead and drop the tank and clean it and check the sending unit. The exhaust is new. The rear shocks and springs getting replaced with the 8.8 so no point in doing that yet. So frame connections and gas tank. Anything else I'm forgetting?

j par

Well-hung Member

Well there you go. I would be working on all that stuff you just mentioned. If it's all going to be done before the motor is running you need to get it done? The underneath stuff start hauling that rear end out start welding those frame connectors on. Get that new rear end in there and what about the transmission again?What other bottom stuff do you think I need?? From the doors up everything underneath is gonna be brand new. The rear end I'm not really gonna mess with yet because I have the 8.8 I'm gonna put in it.

I could go ahead and drop the tank and clean it and check the sending unit. The exhaust is new. The rear shocks and springs getting replaced with the 8.8 so no point in doing that yet. So frame connections and gas tank. Anything else I'm forgetting?

Dartfreak75

Restore it, Dont part it!

It looks good. I will get some pics for you tomorrow.how is all the frame work.... in the back where the leaf shackles mount?

Sounds like a plan. I have 2 transmissions to choose from one a 904 lockup the other is a 999 non lock. The 999 is the plan it was the original trans with my engine. But I got that 904 for a backup and I just got a b&m 360 spi flexplate so I can use the a different torque converter if need be.Well there you go. I would be working on all that stuff you just mentioned. If it's all going to be done before the motor is running you need to get it done? The underneath stuff start hauling that rear end out start welding those frame connectors on. Get that new rear end in there and what about the transmission again?

Yes that's the color I was thinking of, like your choice! Glade to hear you are still working. If you get it down to bare metal get some primer on it right away, even then primer will start to have surface rust issues. Most primers are porous, to help give paint something to grip to, so it also wants to suck up moisture like a sponge. Epoxy is the way to go if it has to sit for a length of down time...Keep us posted enjoying your thread.I wonder how much it would rust if I went ahead and started sanding and blasting it to bare metal in three weeks time?

74 DART'

Well-Known Member

I think my Dart is starting to get jealous of yours!! Yours is actually getting worked on lol! Keep it up man!

Now we're cookin'

Rock on!

Dartfreak75

Restore it, Dont part it!

Thanks man! When I start thinking about everything that has to be done it gets very overwhelming but when I step back and look at it and see my vision for it it keeps me motivated. The reality is started to hit me this is gonna take longer than expected. My time to actually work on the car is so limited, between work and family its really hard to find good quality time to spend just working with no interruptions. I have to make the most of an hour or two when I get it. LolView attachment 1715340709

I think my Dart is starting to get jealous of yours!! Yours is actually getting worked on lol! Keep it up man!

74 DART'

Well-Known Member

I totally understand. Mine has been sitting in the garage since the end of 2016. Work and 3 kids ( one being a 6 month old) doesn’t leave much time for my car. Dislocated my left shoulder 2 weeks ago so I’m still recovering from that. Spent this weekend off working on a corner pantry I’m building for my wife. Got a couple other house projects to do then should be good for awhile. I’m going to try hard to get some stuff done on the Dart this summer!!Thanks man! When I start thinking about everything that has to be done it gets very overwhelming but when I step back and look at it and see my vision for it it keeps me motivated. The reality is started to hit me this is gonna take longer than expected. My time to actually work on the car is so limited, between work and family its really hard to find good quality time to spend just working with no interruptions. I have to make the most of an hour or two when I get it. Lol

Dartfreak75

Restore it, Dont part it!

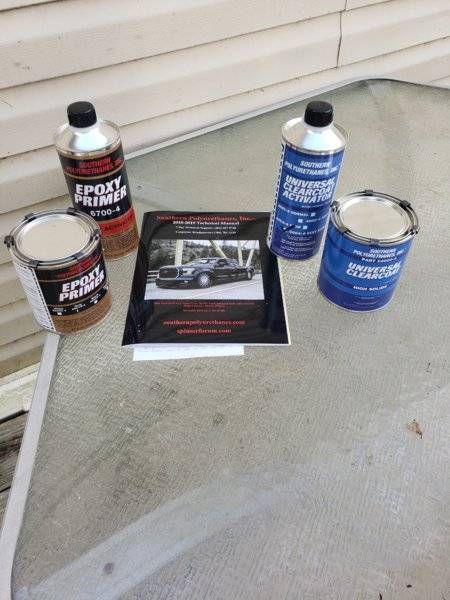

Ok good news. I ordered my epoxy and clear from southern polyurethane (spi) today he said it would be here in 1 to 3 days!! Barry gave me a number to call for my basecoat I called him today he was super helpful and not that much more expensive then the cheap crap paint. He told me for the color I'm using i need to use an underlying coat, like a tricoat system under the basecoat but using that it will give me better coverage and a better color. For around 200 bucks for a quart unreduced vs 130 a quart premixed.

moparmat2000

Well-Known Member

Glad to hear about the progress. If you are going to do any sandblasting i recommend not sandblasting the exterior panels, as sandblasting can warp the sheetmetal. I would limit that to door jambs, under carriage, trunk, wheel wells etc. I would only sandblast what you can dust off and epoxy prime to seal up in a single day. Leaving it bare metal for days or weeks one end it will flash rust quickly. Post up progress pix.

Dartfreak75

Restore it, Dont part it!

Thanks yes I am only sandblasting the frame rails inner fenders engine bay trunk etc. The rest of the the stripping I'm gonna use a electric sander and a strip wheel on a angle grinder. The under carriage and firewall forward is my first priority.Glad to hear about the progress. If you are going to do any sandblasting i recommend not sandblasting the exterior panels, as sandblasting can warp the sheetmetal. I would limit that to door jambs, under carriage, trunk, wheel wells etc. I would only sandblast what you can dust off and epoxy prime to seal up in a single day. Leaving it bare metal for days or weeks one end it will flash rust quickly. Post up progress pix.

Dartfreak75

Restore it, Dont part it!

Talk about fast service. I ordered my primer and clearcoat from spi at 1pm yesterday. I was outside working on my car a while ago around 5pm and ups pulled in the driveway and handed me this! I couldnt believe it.

Dartfreak75

Restore it, Dont part it!

I got a little bit done today on my car I straightened out my bent radiator support. And started sanding on the engine bay some more I have a question what is the best way to protect the bulkhead during sanding and spraying? I wish i had an old connection i could plug into it. Anyone have a scrap harness that has the bulkhead connection on it? Or a better idea?

moparmat2000

Well-Known Member

Push the metal tangs inward , and pop bulkhead connector out at firewall, lay it on the floor of the car, and tape over the firewall hole. Heck, DMT makes new gaskets for it.

Dartfreak75

Restore it, Dont part it!

Thanks i didn't even think about that!! Am gonna get some plastic from work to cover the holes to keep the sandblasting media out of the inside of the car. So I can cover that hole too!Push the metal tangs inward , and pop bulkhead connector out at firewall, lay it on the floor of the car, and tape over the firewall hole. Heck, DMT makes new gaskets for it.

On the bulkhead connector, blast it with baking soda, just the common food store stuff, before you remove it, it will clean the connectors, you will thank me later, when your wiring has a clean connection.Thanks i didn't even think about that!! Am gonna get some plastic from work to cover the holes to keep the sandblasting media out of the inside of the car. So I can cover that hole too!

Tractor supply sells a hand held QT blaster for like $20, dump a box of store brand baking soda in it, and it will literally polish the connectors.

This is a set of emblems off my grandpas farm tractor, that my uncle restored.

He said he could not get the trim bright, 10 seconds with a cheap blaster, and 50 cents worth of soda. Before and after, you decide.

Dartfreak75

Restore it, Dont part it!

Cool deal thank you!! I wonder if I can modify my blaster to use the soda. I have one of the blast out of a bucket style setup. I have seen home made soda blasters using a spray nozzle and a 2 liter bottle! I will do some research I may just buy the canister style blaster. What all media can you run out of yours?On the bulkhead connector, blast it with baking soda, just the common food store stuff, before you remove it, it will clean the connectors, you will thank me later, when your wiring has a clean connection.

Tractor supply sells a hand held QT blaster for like $20, dump a box of store brand baking soda in it, and it will literally polish the connectors.

This is a set of emblems off my grandpas farm tractor, that my uncle restored.

He said he could not get the trim bright, 10 seconds with a cheap blaster, and 50 cents worth of soda. Before and after, you decide.

View attachment 1715342575

Dartfreak75

Restore it, Dont part it!

Here is the one I have it looks exactly like yours but has a hose instead of the canister!

Dartfreak75

Restore it, Dont part it!

I love this picture Marshall loves to get in every picture I take and he even posed in this one lol

-