:cheers::cheers::cheers:

I am the proud owner of Made in USA by pheonix powder coatings,one pair of beautiful bbm valve covers!!

These things are frikkin nice and Im sure they will draw EVERY EYE!

I did my best to capture the alien silver metal flake which has me continually marvelling at the miriad reflections it contains. VERY HYPNOTISING!!

Bob and Leanna;thanks for teaming together to get these to me. They re very inspirational to look at.

Im sure I will need to leave them accesible as the build progresses in order to draw more inspiration and get the work done.

I was in the doc's office yesterday. It appears my oxy pain meds are loosing thier effectiveness and unfortunately there is nothing my doc can do. Chronic pain is VERY tough to treat. He literally said the medical proffesion sucks at treating it,as there are not a ton of drugs available

I was taking something called Gabapentin at one time. It was effective at relief of all the minor stuff but very expensive and I found the cost vs relief ratio not very effective as the oxy was much better. Not anymore...

Sorry for driving off on a tangent but I feel I need to explain why there hasnt been anything done as of late...it seems every day is tougher to move about..

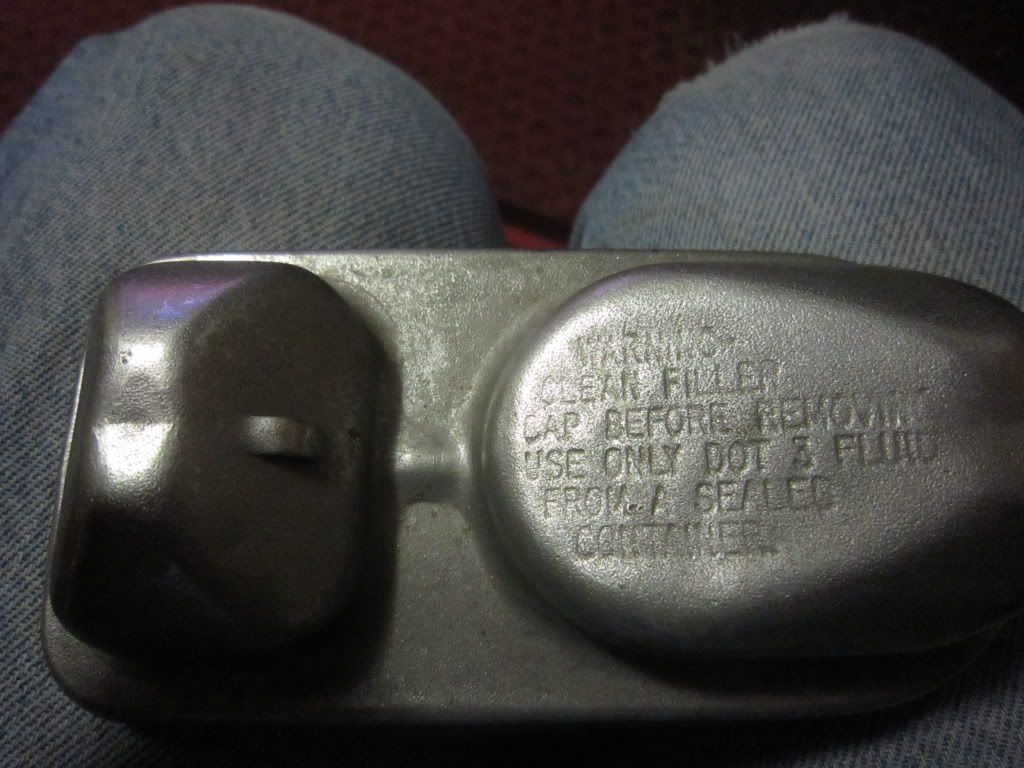

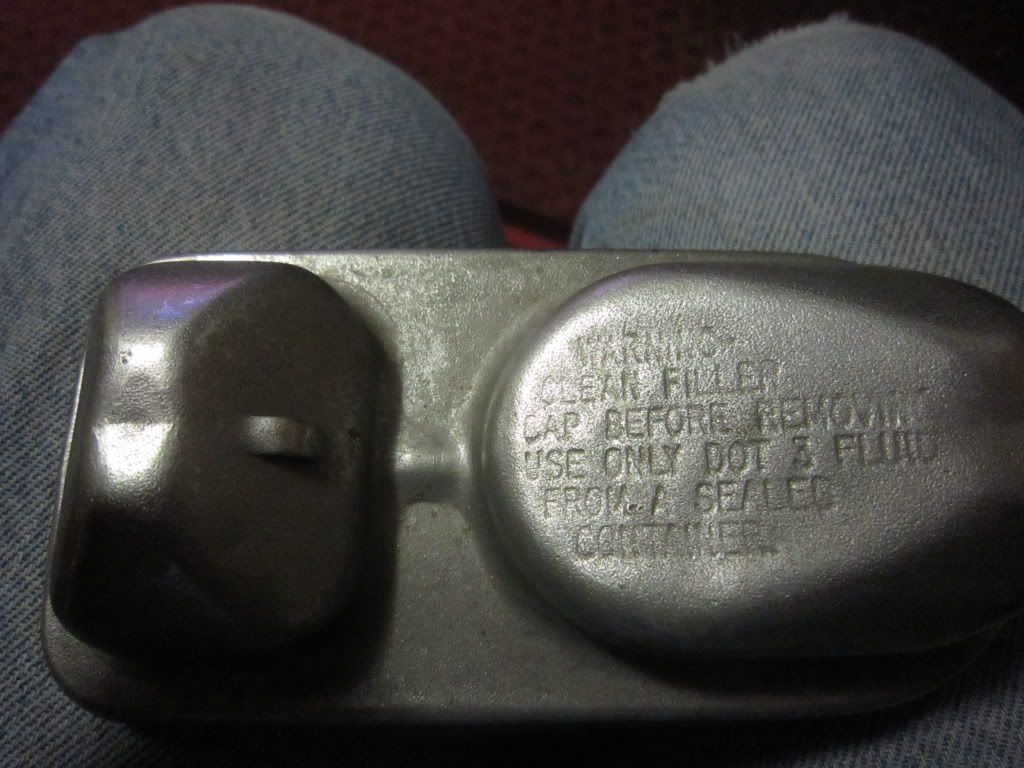

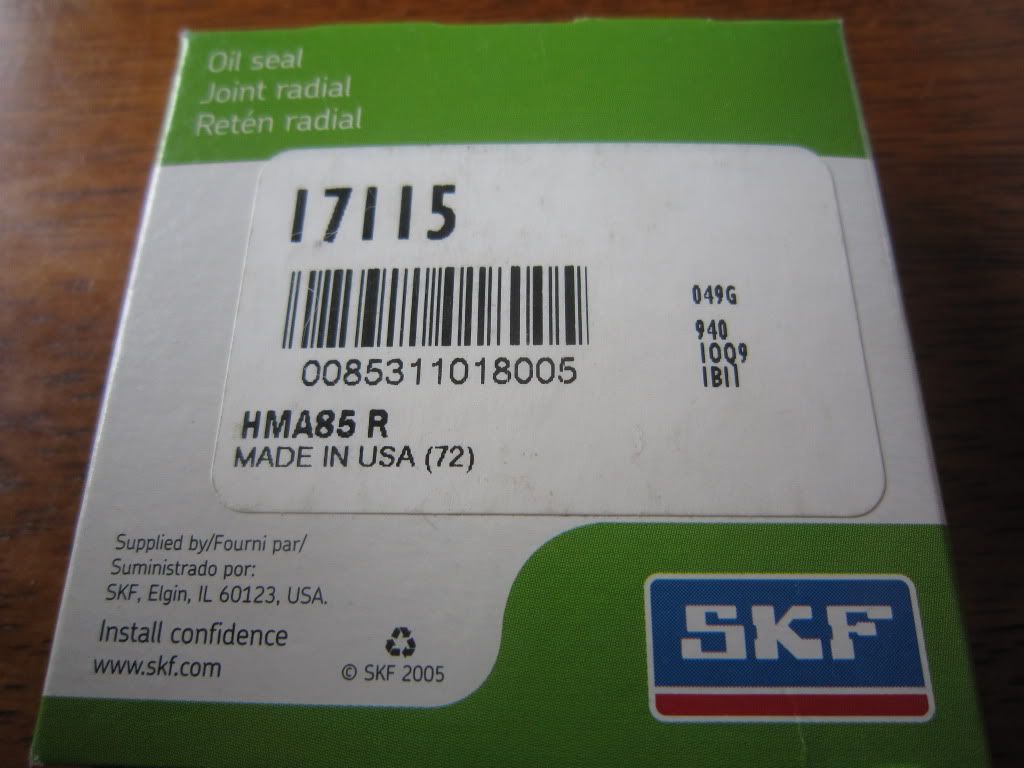

I also bought some new grease seals from the local jobber for my KH brake system.

They are SKF and made here!!!

They differ in construction from the national seal I pulled out,but in a good way. So solid looking I bet I could remove them without tweaking.

National on the right,SKF on the left.

Havent made any progress with the master,but all the other brake parts are blasted and waiting.

I did have to mod my little 110 arc welder to safely use my carbon arc torch. I was simply clamping cables together with vice grips!! Pertty sparks...

I'll get a few pics up of the connecter mod later.