Show us your home made tools

- Thread starter fishy68

- Start date

-

TrailBeast

AKA Mopars4us on Youtube

TrailBeast

AKA Mopars4us on Youtube

Here is a big "F'n" tool I made tonight. I think it might be Mopar specific. After I cleaned it up, I lengthened the "handle".

Care to guess what it is for?

C

Hood spring tool.

Had a winch but no frame. Frame unbolts into 3 sections for storage. Not mobile but I roll the car out from under the engine. Pulling a 340 here.

View attachment puller.jpg

View attachment puller.jpg

clhyer

Well-Known Member

- Joined

- Feb 24, 2007

- Messages

- 3,733

- Reaction score

- 322

fishy68

Tyr Fryr's Inc.

My big "F" is used to hold the water pump pulley while the fan clutch is loosened or tightened. Works good, leaves what little room that is there for the fan clutch wrench.

C

Good idea. I remember taking the fan off my 93 318 when I had to replace the water pump and man was it a bugger without anything to hold the pulley. Finally got it using the impact method. Put my big ole wrench on it and smacked it 3 or 4 times with a 2 lb. sledge and it popped loose. Tightened it the same way. Not the ideal method but it worked.

clhyer

Well-Known Member

- Joined

- Feb 24, 2007

- Messages

- 3,733

- Reaction score

- 322

Good idea. I remember taking the fan off my 93 318 when I had to replace the water pump and man was it a bugger without anything to hold the pulley. Finally got it using the impact method. Put my big ole wrench on it and smacked it 3 or 4 times with a 2 lb. sledge and it popped loose. Tightened it the same way. Not the ideal method but it worked.

LOL - I did my first one the same way. I need to replace the fan clutch on a friends 2003 Dakota next week. Told him I would do it after I made this wrench...

C

LOL - I did my first one the same way. I need to replace the fan clutch on a friends 2003 Dakota next week. Told him I would do it after I made this wrench...

C

silvadful

Well-Known Member

SirDan

Well-Known Member

nice. how d you make the hinge for your metal break? got any good pics of that?

X2 my dad has been thinking of making one of these for a while now. there too damned expensive to buy!

Inertia

Well-Known Member

I made these tools over 30 yrs ago..

1st is for doing up pinion nut, on or off the car,

2nd, an axle remover/slide hammer made from an old diff,

3rd, is a pinion depth tool, using axle centreline to the face of pinion with a 0.500 piece to transfer the pinion surface, enabling use vernier caliper..

1st is for doing up pinion nut, on or off the car,

2nd, an axle remover/slide hammer made from an old diff,

3rd, is a pinion depth tool, using axle centreline to the face of pinion with a 0.500 piece to transfer the pinion surface, enabling use vernier caliper..

Attachments

-

Sundeck frame 014.jpg56.9 KB · Views: 1,903

-

Sundeck frame 013.jpg52.6 KB · Views: 1,866

-

Sundeck frame 012.jpg57.6 KB · Views: 1,911

-

P1010047.jpg126.1 KB · Views: 1,866

-

P1010046.jpg56.1 KB · Views: 1,898

-

P1010043.jpg50.9 KB · Views: 1,873

-

P1010041.jpg48.9 KB · Views: 1,890

-

P1010040.jpg46.9 KB · Views: 2,285

67Dart273

Well-Known Member

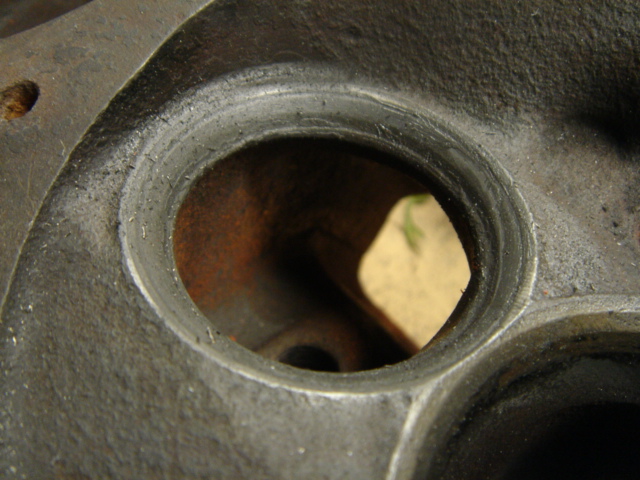

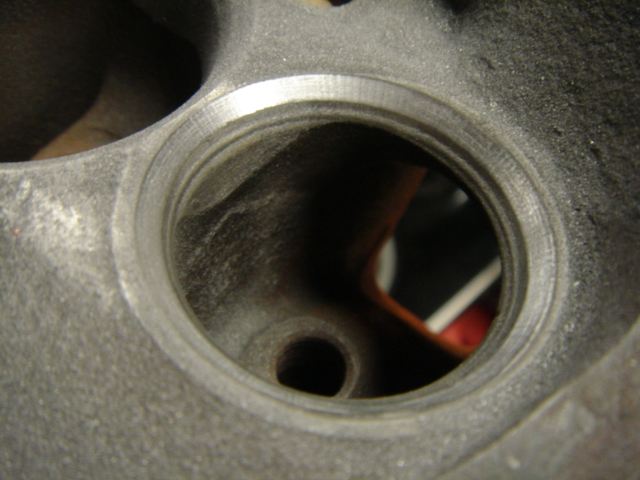

My meager attempt at a homemade A arm bushing tool.

Got a steel pipe coupler. These are normally used on the ends of 20' lengths of pipe for thread protection. Around here, only malleable iron couplers are used operationally.

I clamped it in my Drill / Mill and cut a notch for clearance. You don't need a mill, you can do this with a hacksaw, as it's not critical

The bolt is a scrap of 1/2" allthread.

I bought some (called locally) "flat plate washers." These are not only very large OD, like a fender washer, they are thick as can be, maybe 3/16" ? "I used two" LOL

I could've gotten the new ones in, but the arms really should be cleaned up

Got a steel pipe coupler. These are normally used on the ends of 20' lengths of pipe for thread protection. Around here, only malleable iron couplers are used operationally.

I clamped it in my Drill / Mill and cut a notch for clearance. You don't need a mill, you can do this with a hacksaw, as it's not critical

The bolt is a scrap of 1/2" allthread.

I bought some (called locally) "flat plate washers." These are not only very large OD, like a fender washer, they are thick as can be, maybe 3/16" ? "I used two" LOL

I could've gotten the new ones in, but the arms really should be cleaned up

Attachments

Sc2ner

Well-Known Member

fishy68

Tyr Fryr's Inc.

That's a hoss for sure!

Del, Nice bushing puller

younggun2.0

Well-Known Member

Idaho

Well-Known Member

- Joined

- Oct 17, 2006

- Messages

- 2,595

- Reaction score

- 274

just made my sheet metal brake this last weekend.

bends meterial up to 1/8" x 36" wide.

Nice. I like the seat mount too.

(Check out my thread to see how I used your spring slider idea)

younggun2.0

Well-Known Member

just made my sheet metal brake this last weekend.

bends meterial up to 1/8" x 36" wide.

Nice. I like the seat mount too.

(Check out my thread to see how I used your spring slider idea)

looks good man.

fishy68

Tyr Fryr's Inc.

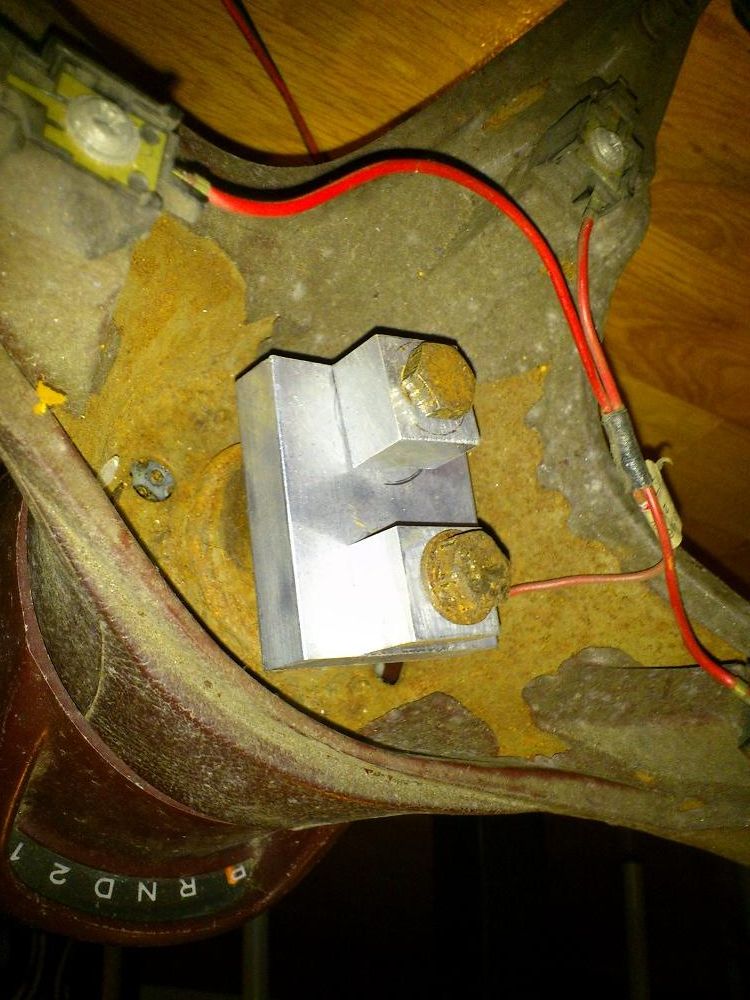

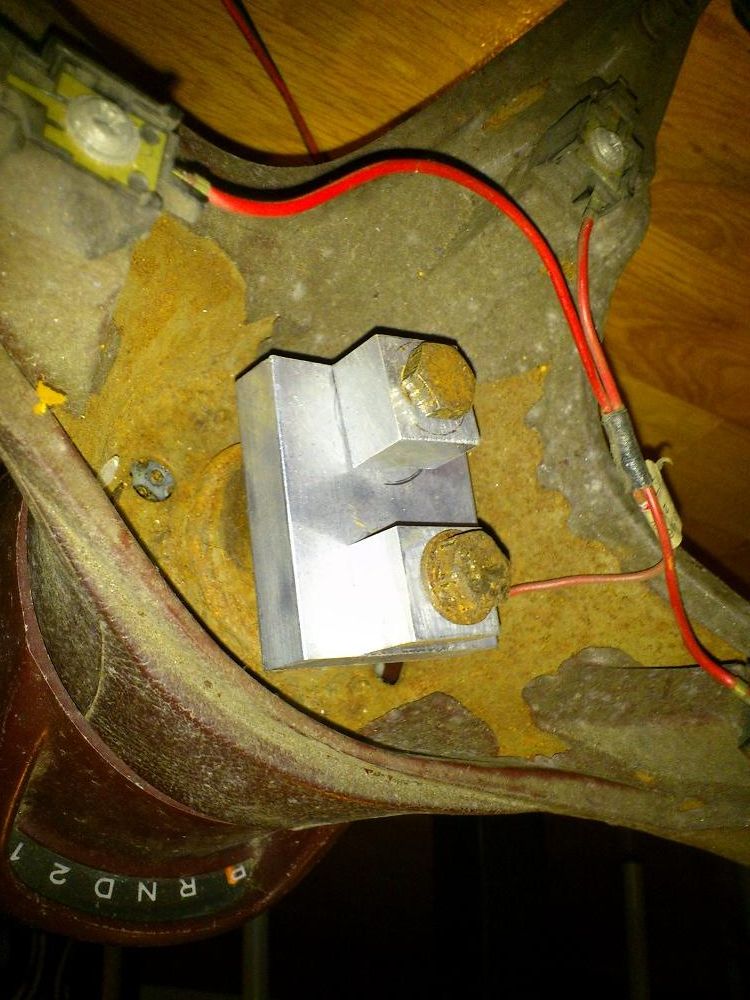

I made these tools over 30 yrs ago..

1st is for doing up pinion nut, on or off the car,

2nd, an axle remover/slide hammer made from an old diff,

3rd, is a pinion depth tool, using axle centreline to the face of pinion with a 0.500 piece to transfer the pinion surface, enabling use vernier caliper..

Nice job. I don't do much differential work anymore so I don't need one of these real bad but I have a couple rounds pieces of steel that just fit into a 8-3/4 carrier bearing opening so I may have to dig up some round rod and make one of these.

fishy68

Tyr Fryr's Inc.

just made my sheet metal brake this last weekend.

bends meterial up to 1/8" x 36" wide.

http://s370.photobucket.com/user/johnnydart_photo/media/DSCN0672-Copy_zps277a4acc.jpg.html

Nice job man!

pishta

I know I'm right....

home made valve seat scraper...cut slow with cordless drill and use cutting oil...

Thanks this thread gave me some good ideas. Maybe some one can get some good ideas from what I've made.

1: Degreeing wheel made of a degreeing wheel printed on a 11 x 17 inches paper then glued on a pizza cardboard. Took a welding rod that I've bent to a pointer.

2: Piston stop. Using it when the head is removed when I degreeing a cam.

3: A copper pipe flattened. Placing the flattened copper pipe thing behind a hole then welding the hole together without the weld sticking to it. On aluminium use a flat steel piece behind instead.

4: Steering wheel puller.

5: Modified puller to pull the steering column thingy.

1: Degreeing wheel made of a degreeing wheel printed on a 11 x 17 inches paper then glued on a pizza cardboard. Took a welding rod that I've bent to a pointer.

2: Piston stop. Using it when the head is removed when I degreeing a cam.

3: A copper pipe flattened. Placing the flattened copper pipe thing behind a hole then welding the hole together without the weld sticking to it. On aluminium use a flat steel piece behind instead.

4: Steering wheel puller.

5: Modified puller to pull the steering column thingy.

-