There has to be some grounding going on.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Someone please help me

- Thread starter Iwannabefast318

- Start date

-

Absolutely, without a doubt!There has to be some grounding going on.

But I suddenly see a lot of potential in all the clapped out four and six cylinder fox bodies sitting and rotting around here!

Exactly! Let the brand X’er’s roll over in there graves and LOL all the want. Hot rodding is alive and well!

first thing as always... have you put a timing light on it at idle? What is the initial timing?

Please get some terminals and a crimper and fix the wiring...

Please get some terminals and a crimper and fix the wiring...

67Dart273

Well-Known Member

Buddy TWISTING WIRES AROUND TERMINALS is no way to try and make connections.

1...As others have said the ignition module MUST BE GROUNDED. Not by a twisted wire, but BOLTED to a GROUND point.

2...The "whatever connectors" you are using into the ECU are QUESTIONABLE. I wasn't there, are they firm and tight on the terminals, or can you just lift them off? If so, pull that apart and get a pigtail connector. Last I knew, you could buy those and NAPA

3...I can't see, DO YOU HAVE a jumper between either the battery NEG and the body, or from the engine to the body? The engine, block, and body all must be grounded together.

4...GET THAT distributor pickup ( the trigger, the 2 wire black connector ) GET THAT away from the plug wires. "Dress" it close to the engine/ firewall for a shielding effect to prevent the plug wires (or other wiring) from inducing false triggers and cause misfiring

5....BALLAST resistor.......again, twisting wires is not "it." Buy yourself some "flag" push on terminals and do that right. TAPE on that ballast is NOT GOING to go far. Those ballasts run HOT and it will turn that tape into a "crisp" and may catch fire.

6...PLUS battery terminal.....how tight are those wires, can you pull on them and they "won't" come out? If they do, "redo" that. I do use those temporary battery terminals sometimes, TEMPORARY but you have to pay attention and get everything in there TIGHT

7...Can you detail how you have the coil/ ballast/ ECU wired?

One end of ballast goes to coil +. On your Ford does it have two small connectors on the starter solenoid? "I" and "S?"

Other end of ballast goes to key switched power. That terminal should also feed power to the box.

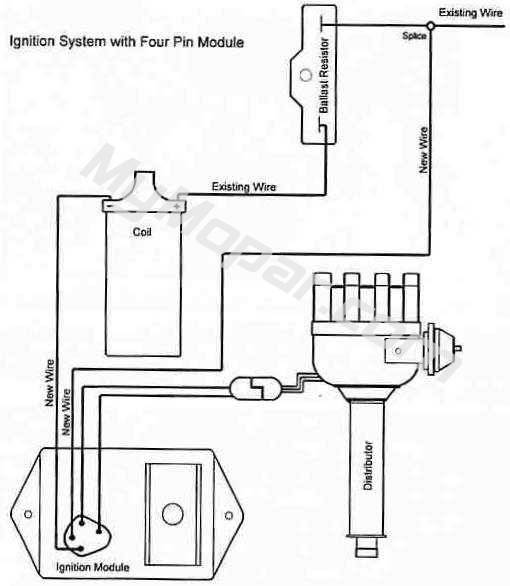

The "basic" diagram:

The wire at far top right goes to switched "run" power from the key. Your original harness may or may not have a RESISTOR WIRE IN the harness. Make sure that switched power TO THE ballast is actually "same as battery"

1...As others have said the ignition module MUST BE GROUNDED. Not by a twisted wire, but BOLTED to a GROUND point.

2...The "whatever connectors" you are using into the ECU are QUESTIONABLE. I wasn't there, are they firm and tight on the terminals, or can you just lift them off? If so, pull that apart and get a pigtail connector. Last I knew, you could buy those and NAPA

3...I can't see, DO YOU HAVE a jumper between either the battery NEG and the body, or from the engine to the body? The engine, block, and body all must be grounded together.

4...GET THAT distributor pickup ( the trigger, the 2 wire black connector ) GET THAT away from the plug wires. "Dress" it close to the engine/ firewall for a shielding effect to prevent the plug wires (or other wiring) from inducing false triggers and cause misfiring

5....BALLAST resistor.......again, twisting wires is not "it." Buy yourself some "flag" push on terminals and do that right. TAPE on that ballast is NOT GOING to go far. Those ballasts run HOT and it will turn that tape into a "crisp" and may catch fire.

6...PLUS battery terminal.....how tight are those wires, can you pull on them and they "won't" come out? If they do, "redo" that. I do use those temporary battery terminals sometimes, TEMPORARY but you have to pay attention and get everything in there TIGHT

7...Can you detail how you have the coil/ ballast/ ECU wired?

One end of ballast goes to coil +. On your Ford does it have two small connectors on the starter solenoid? "I" and "S?"

Other end of ballast goes to key switched power. That terminal should also feed power to the box.

The "basic" diagram:

The wire at far top right goes to switched "run" power from the key. Your original harness may or may not have a RESISTOR WIRE IN the harness. Make sure that switched power TO THE ballast is actually "same as battery"

Last edited:

Twisted wire on the left.There has to be some grounding going on

67Dart273

Well-Known Member

Not dependable.

Good catch, did not see that. Yikes!Twisted wire on the left.

Oh my goodness. I'm speechless.

hotrod swinger

Well-Known Member

Lol, probably goes without saying, but that’s the first time I’ve seen an ECU mounted to a master cylinder with a plastic zip tie.

Where is Dave Freiburger for the zip tie moment?!?!?!

OH! Here he is!!!!

OH! Here he is!!!!

Close race with the hose clamp transmission mount!

NOW THATS why I wanted pics!

Iwannabefast318

Well-Known Member

So this made me Crack up soo hard lol, I don't have a lot of money nor time to be doing this, usually weekends I can work on it but through the week I have about 100$ a week and about 2-3hrs of work time depending on if I get 8hrs of sleep ill try the fix the harness things with all new wire and re route it along the factory wire path so its not up against the headers, and I'm still failing to se why this would cause it to die if I barely touch the throttle under load. I'm also working on videos for YouTube, when I have the time I'll post a video and send links, you guys have been so responsive and helpful . Thank yall so muchLol, probably goes without saying, but that’s the first time I’ve seen an ECU mounted to a master cylinder with a plastic zip tie.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 25,998

- Reaction score

- 13,310

Ok I'm in, see Note-4,

If you find goofy strobing, then;

Reverse the polarity on the pick-up. You will have to change the initial timing. You will not need a timing light.

After the polarity is reversed, bring the #1 cylinder to TDC on the compression stroke. Then look on the balancer to verify TDC.

Next back the balancer up to around 10* advanced. Now remove the coil wire out of the cap, and near ground it, about .25 inch or so. Next push the distributor V-can back towards the firewall to nearly as far as it will go. Next, turn on the ignition key to "run". Go back to the distributor and while watching the near-grounded coil wire, watching for a spark, slowly pull the V-can towards the rad, stopping when you see the spark or hear the snap. (See note-1) Stop. tighten the hold down. Mark the outside of the distributor, where the rotor is pointing. Install the cap. Make sure the wire for #1 cylinder is directly above the mark you made. If it is not, move it there and then move the rest of them according to the firing order of 18436572, going CW. Reinstall the coil wire. Start the engine. Roadtest it.

Note-1

If you don't see or hear the spark, you may be turning the distributor too slowly, try a lil faster. If still no spark verify that the ECU is working; do the one-spark test.

Note 1B

On the Mopar ECU, it will spark every time you turn the key from off to run and back.Every time; go look for it. This proves that everything (except the pick-up) is working. If no spark, the first check is to be sure the case of the ECU is seeing the Battery negative. More tests to follow as may be needed.

FWI, the signal coming out of the pick-up is very tiny, therefore your connections have to be very good.

Note-2

if the engine doesn't start, remove all the plugs, dry them off. Put a lil squirt of any motor-oil, into each cylinder then wind it over for say 10 seconds to blow out the excess and distribute the oil around the rings.

Clean up the mess, then re-install the dry plugs. Now try again.

Note-3

If I am right about the polarity thing, then the engine will rev right up. There is a slim possibility that I am wrong about the polarity, and then the engine will run worse, but it will idle just fine.

Note-4

You can definitively prove that the polarity is wrong. Just hook up your timing light. Start the engine. Verify that the strobing of your light is working correctly. Shine it on any reflective surface, Now, while watching the strobing, attempt to rev up the engine. If the strobing immediately goes crazy with missed strobes or double strobes or strobes out of time; then the polarity is forabsolutely reversed; just flip the wires around, and reset the base-timing.

If you find goofy strobing, then;

Reverse the polarity on the pick-up. You will have to change the initial timing. You will not need a timing light.

After the polarity is reversed, bring the #1 cylinder to TDC on the compression stroke. Then look on the balancer to verify TDC.

Next back the balancer up to around 10* advanced. Now remove the coil wire out of the cap, and near ground it, about .25 inch or so. Next push the distributor V-can back towards the firewall to nearly as far as it will go. Next, turn on the ignition key to "run". Go back to the distributor and while watching the near-grounded coil wire, watching for a spark, slowly pull the V-can towards the rad, stopping when you see the spark or hear the snap. (See note-1) Stop. tighten the hold down. Mark the outside of the distributor, where the rotor is pointing. Install the cap. Make sure the wire for #1 cylinder is directly above the mark you made. If it is not, move it there and then move the rest of them according to the firing order of 18436572, going CW. Reinstall the coil wire. Start the engine. Roadtest it.

Note-1

If you don't see or hear the spark, you may be turning the distributor too slowly, try a lil faster. If still no spark verify that the ECU is working; do the one-spark test.

Note 1B

On the Mopar ECU, it will spark every time you turn the key from off to run and back.Every time; go look for it. This proves that everything (except the pick-up) is working. If no spark, the first check is to be sure the case of the ECU is seeing the Battery negative. More tests to follow as may be needed.

FWI, the signal coming out of the pick-up is very tiny, therefore your connections have to be very good.

Note-2

if the engine doesn't start, remove all the plugs, dry them off. Put a lil squirt of any motor-oil, into each cylinder then wind it over for say 10 seconds to blow out the excess and distribute the oil around the rings.

Clean up the mess, then re-install the dry plugs. Now try again.

Note-3

If I am right about the polarity thing, then the engine will rev right up. There is a slim possibility that I am wrong about the polarity, and then the engine will run worse, but it will idle just fine.

Note-4

You can definitively prove that the polarity is wrong. Just hook up your timing light. Start the engine. Verify that the strobing of your light is working correctly. Shine it on any reflective surface, Now, while watching the strobing, attempt to rev up the engine. If the strobing immediately goes crazy with missed strobes or double strobes or strobes out of time; then the polarity is forabsolutely reversed; just flip the wires around, and reset the base-timing.

Lol, probably goes without saying, but that’s the first time I’ve seen an ECU mounted to a master cylinder with a plastic zip tie.

ECU needs to be grounded. Alligator clips and 2 feet of wire will get you there. Zip tie down the excess wire.

In box full……

Ok I'm in, see Note-4,

If you find goofy strobing, then;

Reverse the polarity on the pick-up. You will have to change the initial timing. You will not need a timing light.

After the polarity is reversed, bring the #1 cylinder to TDC on the compression stroke. Then look on the balancer to verify TDC.

Next back the balancer up to around 10* advanced. Now remove the coil wire out of the cap, and near ground it, about .25 inch or so. Next push the distributor V-can back towards the firewall to nearly as far as it will go. Next, turn on the ignition key to "run". Go back to the distributor and while watching the near-grounded coil wire, watching for a spark, slowly pull the V-can towards the rad, stopping when you see the spark or hear the snap. (See note-1) Stop. tighten the hold down. Mark the outside of the distributor, where the rotor is pointing. Install the cap. Make sure the wire for #1 cylinder is directly above the mark you made. If it is not, move it there and then move the rest of them according to the firing order of 18436572, going CW. Reinstall the coil wire. Start the engine. Roadtest it.

Note-1

If you don't see or hear the spark, you may be turning the distributor too slowly, try a lil faster. If still no spark verify that the ECU is working; do the one-spark test.

Note 1B

On the Mopar ECU, it will spark every time you turn the key from off to run and back.Every time; go look for it. This proves that everything (except the pick-up) is working. If no spark, the first check is to be sure the case of the ECU is seeing the Battery negative. More tests to follow as may be needed.

FWI, the signal coming out of the pick-up is very tiny, therefore your connections have to be very good.

Note-2

if the engine doesn't start, remove all the plugs, dry them off. Put a lil squirt of any motor-oil, into each cylinder then wind it over for say 10 seconds to blow out the excess and distribute the oil around the rings.

Clean up the mess, then re-install the dry plugs. Now try again.

Note-3

If I am right about the polarity thing, then the engine will rev right up. There is a slim possibility that I am wrong about the polarity, and then the engine will run worse, but it will idle just fine.

Note-4

You can definitively prove that the polarity is wrong. Just hook up your timing light. Start the engine. Verify that the strobing of your light is working correctly. Shine it on any reflective surface, Now, while watching the strobing, attempt to rev up the engine. If the strobing immediately goes crazy with missed strobes or double strobes or strobes out of time; then the polarity is forabsolutely reversed; just flip the wires around, and reset the base-timing.

Iwannabefast318

Well-Known Member

Works just now slowing down, it's getting really hard to keep track of everyone on here, but reverse the polarity? I'm confused, like swap the two wires coming from the coil or distributor, or both, or are you talking about the whole system? Remember this is my very first project car and I got about 2 months worth of hands on experience. I'm a noob basically.Ok I'm in, see Note-4,

If you find goofy strobing, then;

Reverse the polarity on the pick-up. You will have to change the initial timing. You will not need a timing light.

After the polarity is reversed, bring the #1 cylinder to TDC on the compression stroke. Then look on the balancer to verify TDC.

Next back the balancer up to around 10* advanced. Now remove the coil wire out of the cap, and near ground it, about .25 inch or so. Next push the distributor V-can back towards the firewall to nearly as far as it will go. Next, turn on the ignition key to "run". Go back to the distributor and while watching the near-grounded coil wire, watching for a spark, slowly pull the V-can towards the rad, stopping when you see the spark or hear the snap. (See note-1) Stop. tighten the hold down. Mark the outside of the distributor, where the rotor is pointing. Install the cap. Make sure the wire for #1 cylinder is directly above the mark you made. If it is not, move it there and then move the rest of them according to the firing order of 18436572, going CW. Reinstall the coil wire. Start the engine. Roadtest it.

Note-1

If you don't see or hear the spark, you may be turning the distributor too slowly, try a lil faster. If still no spark verify that the ECU is working; do the one-spark test.

Note 1B

On the Mopar ECU, it will spark every time you turn the key from off to run and back.Every time; go look for it. This proves that everything (except the pick-up) is working. If no spark, the first check is to be sure the case of the ECU is seeing the Battery negative. More tests to follow as may be needed.

FWI, the signal coming out of the pick-up is very tiny, therefore your connections have to be very good.

Note-2

if the engine doesn't start, remove all the plugs, dry them off. Put a lil squirt of any motor-oil, into each cylinder then wind it over for say 10 seconds to blow out the excess and distribute the oil around the rings.

Clean up the mess, then re-install the dry plugs. Now try again.

Note-3

If I am right about the polarity thing, then the engine will rev right up. There is a slim possibility that I am wrong about the polarity, and then the engine will run worse, but it will idle just fine.

Note-4

You can definitively prove that the polarity is wrong. Just hook up your timing light. Start the engine. Verify that the strobing of your light is working correctly. Shine it on any reflective surface, Now, while watching the strobing, attempt to rev up the engine. If the strobing immediately goes crazy with missed strobes or double strobes or strobes out of time; then the polarity is forabsolutely reversed; just flip the wires around, and reset the base-timing.

We like pictures. Can we get a picture (or three) of the whole car?

Iwannabefast318

Well-Known Member

I'll try to get some but you guys gotta understand I work, and I'm at work rn, if you give me say an hr, I can have some crappy night photos lolWe like pictures. Can we get a picture (or three) of the whole car?

Take your time brother, take your time….

I applaud you for diving into this project. You'll learn a lot through all of this! None of us were born knowing what we know, but had to start somewhere. Be a sponge and soak up what this forum has to offer you & have fun!So first things first..my 318 is in a mustang. Ik blow me up on why the hell I'd do that but I seriously need help, this place seems friendly and like it has smart ppl to help. So the 318 that is in my 2002 Mustang that was an original V6 Mustang. It is stalling whenever I barely tap the throttle, it idles great, it revs great, it even drives great but as soon as I try to barely go up the RPM it tries to stall on me. even some occasions where I would try to back out of somewhere and it will just shut off. I don't know what the issue is I've tried ignition, I've tried timing, I tried a little work with the carburetor but don't know much about it, it's a stock 2 Barrel. At first I thought it was the 727 transmission that also came with the engine that was messed up and causing parasitic losses but then again this engine puts out roughly 200 horsepower and I'd be willing to bet 30 horsepower could spin this transmission, There is no backfire out of the carburetor there is no fueling issues that I can see although I haven't revved the engine and looked directly over the carburetor as that seems kind of unsafe but I'll do what I have to if I need. Also second question the two screws that are on front of the two-barrel carburetor that came stock with this engine are to adjust fuel enrichment for idle right?

Did I miss how the engine and trans mounts were addressed and any clearance issues?

I have several "spare" running Mopar engine/trans and frequently see brand x and y projects without engines.

My favorite was a nearly rust free 65 ford step side truck for $600.

If I knew a 318/904 would bolt in fairly easy, I would have bought it.

I have several "spare" running Mopar engine/trans and frequently see brand x and y projects without engines.

My favorite was a nearly rust free 65 ford step side truck for $600.

If I knew a 318/904 would bolt in fairly easy, I would have bought it.

Nothing a sawzall and a welder can’t fix…… or fit…Did I miss how the engine and trans mounts were addressed and any clearance issues?

I have several "spare" running Mopar engine/trans and frequently see brand x and y projects without engines.

My favorite was a nearly rust free 65 ford step side truck for $600.

If I knew a 318/904 would bolt in fairly easy, I would have bought it.

Pictures ???

(with the hood open too)

2002 Mustang ^^^

(with the hood open too)

2002 Mustang ^^^

Last edited:

-