Jeezz, the one with the junk, get with it Mam!!!Which one is Frank again??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stop in for a cup of coffee

- Thread starter toolmanmike

- Start date

-

TooljunkieWhich one is Frank again??

zkx14

Duster De-ruster

lolWhich one is Frank again??

He’s even got junk in his screen name!Jeezz, the one with the junk, get with it Mam!!!

Chris you sound so smart. Sometimes!!Not wrong, but that’s not the whole story either. A HUGE part of the labor shift besides just it being cheaper was /is the available, young work force. China being the largest population, had an ungodly number of available workers and those were willing to work in crappy conditions.

that said, China as well as Japan will be having a major demographic problem in the next couple decades. Both of their populations have aged so dramatically due to the stringent population controls ongoing since the 1940s that there are actually more people dying or aging out of the work force in China than there are young people to replace them. Japan is the same way

Chris you sound so smart. Sometimes!!

Hahaha and I didn’t pull that off Google or Wikipedia like some either

I really learned a crap ton during my MBA program that led me to want to know more. Believe it or not, I’m actually actively trying to convince on of the nations leading demographic researchers to let me help him on his next project. He pointed me to a lot of good data sources during my Grad thesis so we have an open dialogue still.

I really learned a crap ton during my MBA program that led me to want to know more. Believe it or not, I’m actually actively trying to convince on of the nations leading demographic researchers to let me help him on his next project. He pointed me to a lot of good data sources during my Grad thesis so we have an open dialogue still.

Fixed it for ya.Way cheaper to make junk.

You firgitted aready??Which one is Frank again??

Sorry, I was thinking Fred, Fabian or maybe Finnegan. Frank, really slipped my mindYou firgitted aready??

It is and itsn't.Let me clarify, it’s not that the product itself is junk, it’s the QC process. I deal with QC daily and with companies all over the globe, in 60 plus countries, those 3 countries have the absolute worst QC protocols of all. And it’s not a single supplier from those countries, it’s generally all of them. I think it’s a cultural thing. For those three countries, it’s widely accepted to have a large defect rate because labor and material is so much cheaper than having to pay for the expensive QC processes.

Arguably some of the best 'smart phones' in the world are made in red China. The QC practices depend on the company back in wherever their engineering is, and goes right through product engineeing and manufacturing. We had it good when the majority of our raw materials and designs were overkill to begin with - most of those countries never had that, and of course we've lost most of what we had.

Gonna haveto change your name to Fargo Frank.You firgitted aready??

Y’all’s so funny!

Then im laughing and have to clue in the wife.

And of course explain how it started.

And i e-mailed champion,told them what i think of their product. 3 times in 3 years. 2x center electrode floating around, now this.

Then im laughing and have to clue in the wife.

And of course explain how it started.

And i e-mailed champion,told them what i think of their product. 3 times in 3 years. 2x center electrode floating around, now this.

You’re not wrong. That’s what is so confusing. Electronic wise, the Asian companies stuff generally speaking are very good. But get to mechanical stuff, even steel, and The QC starts falling off.It is and itsn't.

Arguably some of the best 'smart phones' in the world are made in red China. The QC practices depend on the company back in wherever their engineering is, and goes right through product engineeing and manufacturing. We had it good when the majority of our raw materials and designs were overkill to begin with - most of those countries never had that, and of course we've lost most of what we had.

No way. Too many years with tooljunkie. Although Fargo Frank has a nice ring to it.Gonna haveto change your name to Fargo Frank.

The global top smart phone company is Samsung which came from South Korea. Chinese brands sell the majority of their brands within China and they limit foreign competition so the Chinese brands stay isolated to China.It is and itsn't.

Arguably some of the best 'smart phones' in the world are made in red China. The QC practices depend on the company back in wherever their engineering is, and goes right through product engineeing and manufacturing. We had it good when the majority of our raw materials and designs were overkill to begin with - most of those countries never had that, and of course we've lost most of what we had.

We should be doing that here with our brands.

Ddaddy

Just doing what I do

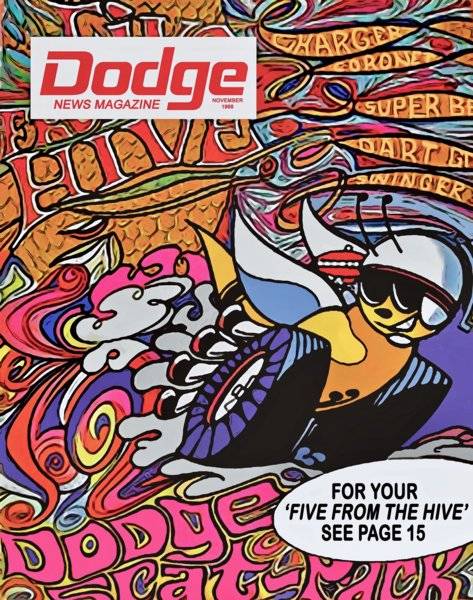

This damn image has made me crazy for 5 years trying to rebuild and restore it.

It was the cover of the November 1968 Dodge News Magazine for the Scat Pack.

The only image of it I could ever find was this postage stamp size crappy one...

I gave up ever finding a good image to work from and have been slowly redrawing it by hand. Today I finally got it to a decent place. Still not done yet, but good enough to share...

It was the cover of the November 1968 Dodge News Magazine for the Scat Pack.

The only image of it I could ever find was this postage stamp size crappy one...

I gave up ever finding a good image to work from and have been slowly redrawing it by hand. Today I finally got it to a decent place. Still not done yet, but good enough to share...

Speaking of mechanical parts, anyone else seeing part shortages at the parts stores? All the ones around me are telling me there having trouble getting parts. I guess their regional distributors are heavily rationing supplies because of the coronavirus having ports and factories closed over there in China

I think the pic I sent you was a big challenge. I was going to ask how it's going, but I didn't want to seem like I'm bugging.This damn image has made me crazy for 5 years trying to rebuild and restore it.

It was the cover of the November 1968 Dodge News Magazine for the Scat Pack.

The only image of it I could ever find was this postage stamp size crappy one...

View attachment 1715473313

I gave up ever finding a good image to work from and have been slowly redrawing it by hand. Today I finally got it to a decent place. Still not done yet, but good enough to share...

View attachment 1715473316

Goigled fargo frank.

Theres a Frank Fargo.

But that’s it.

Theres a Frank Fargo.

But that’s it.

Not that confusing. Most of their steel wasn't great to begin with and they have little incentive to provide better for exports. Whether through ignorance or uncaring doesn't matter. If the specs don't call it out, or the agreed QC doesn't insure it, then they use or do whatever to 'get the job done.' I see this all the time. People in charge who beleive everything can be done by contract and specs. The only way to make that work is with an organization with the skills and knowledge to cover every little detail, and then enforce it (and maybe reward it too). In reality its often better just to hire someone who knows what they are doing.You’re not wrong. That’s what is so confusing. Electronic wise, the Asian companies stuff generally speaking are very good. But get to mechanical stuff, even steel, and The QC starts falling off.

Ddaddy

Just doing what I do

I haven’t seen it. Are you sure you sent it to the right email address? PM me and I will give it to you again.I think the pic I sent you was a big challenge. I was going to ask how it's going, but I didn't want to seem like I'm bugging.

Samsung is a top global cell phone manufacturer. That doesn't mean I-phones are not one the best smart phones in the world. (No I don't have one)The global top smart phone company is Samsung which came from South Korea. Chinese brands sell the majority of their brands within China and they limit foreign competition so the Chinese brands stay isolated to China.

We should be doing that here with our brands.

Makes perfect sense. Wait. This is the tip of the iceberg. Once the world gets a handle on the virus then the recovery can begin. Will take a long time to get caught up with all the goods.Speaking of mechanical parts, anyone else seeing part shortages at the parts stores? All the ones around me are telling me there having trouble getting parts. I guess their regional distributors are heavily rationing supplies because of the coronavirus having ports and factories closed over there in China

WhaaaaaaaaI haven’t seen it. Are you sure you sent it to the right email address? PM me and I will give it to you again.

Ddaddy

Just doing what I do

Never came through...and I was watching for it.Whaaaaaaaa

Ddaddy

Just doing what I do

A couple more images from my continual rework file. Did some work on them today.

Almost ready for large format printing and framing...

Almost ready for large format printing and framing...

-