You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Street Cruser

- Thread starter my68barracuda

- Start date

-

my68barracuda

Well-Known Member

Seems like a pretty stout build.

Getting the air in has ways been the more difficult part of running the slant. The small bore doesn't allow for big valves without shrouding them really bad.. which of course has effect on the flow characteristics from one side of the port to the next. I hear 200-220 cfm is about it. Most I've gotten was 202cfm on one port and the rest 196-199cfm w/1.7 intakes.

port flow numbers. I have 30 degree seats on this head. This gives up some flow at the higher lifts, but comes off the seat faster to get the flow started sooner.

Lift Intake Exhaust

0.050 27.1 17.2

0.100 56.4 35.9

0.150 82.5 55.3

0.200 106.5 70

0.250 126.3 85.2

0.300 144.6 101.2

0.350 156.8 112.1

0.400 163.0 120.1

0.450 168.5 126.4

0.500 172.5 131.1

0.550 173.3 136.3

0.600 173.5 138.1

Last edited:

my68barracuda

Well-Known Member

These numbers are at 10" flow right?

my68barracuda

Well-Known Member

converted to 28 inches, as that is common today.

MOPAROFFICIAL

Oogliboogli

Wish all you slant and iron small block folks were closer.converted to 28 inches, as that is common today.

my68barracuda

Well-Known Member

68 B 061022 - YouTube

a list of the bigger projects completed on the 68 B over the Winter 2021 and Spring 2022 months

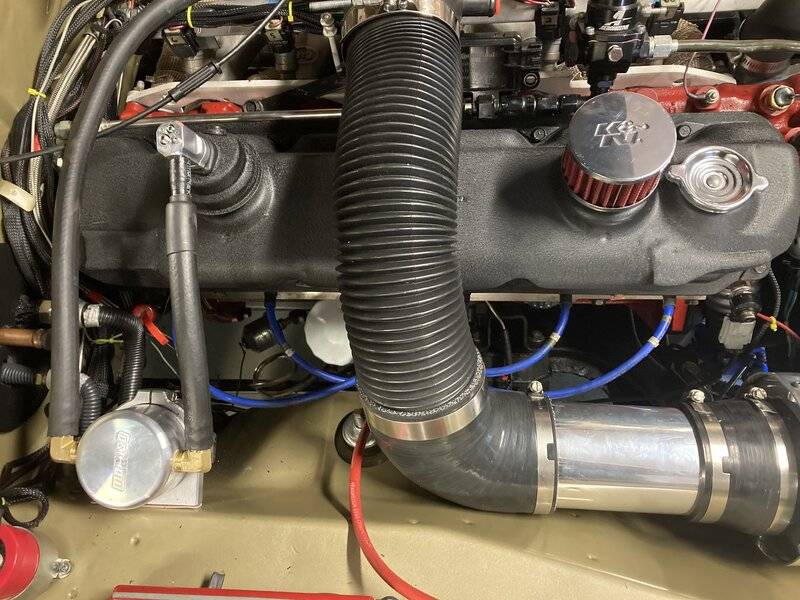

* Installed Roller Rockers, B3 valve train optimization shims, new pushrods, installed

valve spring retainer bushings, modified the valve cover to accept the higher positioned valve train

* Installed Tuff Wheel and adapter

* Re built 8.75 differential with new 3:55 ring and pinion

* Installled a Wagner adjustable PCV and Moroso vapor catch can

* Built brackets and trim necessary to mount quad headlights and custom grill work.

I am quickly running out of reasons to not drive this car.

I had rolled the odometer back to zero, when I started this project. The odometer is currently setting on 260 miles.

It is a 'Go' from there.

I will post a few more photos of the projects listed.

a list of the bigger projects completed on the 68 B over the Winter 2021 and Spring 2022 months

* Installed Roller Rockers, B3 valve train optimization shims, new pushrods, installed

valve spring retainer bushings, modified the valve cover to accept the higher positioned valve train

* Installed Tuff Wheel and adapter

* Re built 8.75 differential with new 3:55 ring and pinion

* Installled a Wagner adjustable PCV and Moroso vapor catch can

* Built brackets and trim necessary to mount quad headlights and custom grill work.

I am quickly running out of reasons to not drive this car.

I had rolled the odometer back to zero, when I started this project. The odometer is currently setting on 260 miles.

It is a 'Go' from there.

I will post a few more photos of the projects listed.

my68barracuda

Well-Known Member

The B3 rocker shaft shims significantly reduced the travel of the rocker rollers across the valve stem tip.

But they also moved the rocker shaft up over .200 and to make that work I needed new pushrods and a modified valve cover.

I added up lifts on the ends of the valve cover for clearance and moved the vapor containing baffles to the outside of the valve cover. To make a nicer routing of the PCV piping I swapped PCV and air intake positions.

But they also moved the rocker shaft up over .200 and to make that work I needed new pushrods and a modified valve cover.

I added up lifts on the ends of the valve cover for clearance and moved the vapor containing baffles to the outside of the valve cover. To make a nicer routing of the PCV piping I swapped PCV and air intake positions.

Last edited:

my68barracuda

Well-Known Member

The goal of the new grill was to add an engine air intake, reminiscent of what was hot Rod stuff in the 60's and at the same time make it look like something Mopar could have done in 1968 and at the same time not do any changes that would impact re installing the original OE head lights and bezels.

This was an interesting project, and its done.

This was an interesting project, and its done.

my68barracuda

Well-Known Member

The OE steering wheel on this 68 Barracuda is just absolutely perfect. Has a nice shine, no cracks.

I am wanting to drive the car aggressively and I felt that a thicker steering wheel rim would give better turning grip and at the same time I would not be stressing the nice OE steering wheel. I like the way the Tuff Wheel looks and feels.

I am wanting to drive the car aggressively and I felt that a thicker steering wheel rim would give better turning grip and at the same time I would not be stressing the nice OE steering wheel. I like the way the Tuff Wheel looks and feels.

my68barracuda

Well-Known Member

Been doing some local driving to run up a few break in miles and to establish the reliability of the car.

The photo below is of the car using it as a Grocery Getter. That day in the parking lot independently had two sets of folks approach me saying

"that car is just beautiful, what is it?"

I now have 330 miles on the car. The last trip was a 20 mile out and back, all highway. The fuel milage was 17.9 mpg on that stint.

Pulled the sparkplugs to do a compression test

the cranking pressure for 1 to 6 are

195, 190, 183, 190, 183, 185

I also adjusted the valves

I have the AF and VE tables adjusted good enough that the car starts and drives easily. No bogs or hesitations.

I think I can tune it a bit better for more performance and economy.

The photo below is of the car using it as a Grocery Getter. That day in the parking lot independently had two sets of folks approach me saying

"that car is just beautiful, what is it?"

I now have 330 miles on the car. The last trip was a 20 mile out and back, all highway. The fuel milage was 17.9 mpg on that stint.

Pulled the sparkplugs to do a compression test

the cranking pressure for 1 to 6 are

195, 190, 183, 190, 183, 185

I also adjusted the valves

I have the AF and VE tables adjusted good enough that the car starts and drives easily. No bogs or hesitations.

I think I can tune it a bit better for more performance and economy.

Last edited:

my68barracuda

Well-Known Member

I had always planned at some point in time to convert the 68 Baracuda to a 4 speed car. When I put the car together years ago I put in the pedals, 4 speed hump and carpet set.

Some time ago I had an adapter plate made that mates a SBM bell to a slant, so that is part of the project also. The SBM bell and 130 tooth flywheel opens a world of performance clutches.

Using straight dowels the adapter plate and bell indicated in really close.

Some time ago I had an adapter plate made that mates a SBM bell to a slant, so that is part of the project also. The SBM bell and 130 tooth flywheel opens a world of performance clutches.

Using straight dowels the adapter plate and bell indicated in really close.

my68barracuda

Well-Known Member

Using an aluminum case a833 OD transmission out of a 1975 F body.

I worked with Brewers Transmissions for the Hurst Shifter, shift rods and bushings and clips. The 1-2 and reverse rods are Mopar A body the 3-4 rod is a F body OD part.

Interesting thing about this transmission is it is stamped as a 230 three speed transmission on the s/n pad. Just another day in the Mopar assembly plant.

The Speedometer gear is a different design than what I am familiar with.

I plan to have the transmission gone through internally prior to installing it.

I worked with Brewers Transmissions for the Hurst Shifter, shift rods and bushings and clips. The 1-2 and reverse rods are Mopar A body the 3-4 rod is a F body OD part.

Interesting thing about this transmission is it is stamped as a 230 three speed transmission on the s/n pad. Just another day in the Mopar assembly plant.

The Speedometer gear is a different design than what I am familiar with.

I plan to have the transmission gone through internally prior to installing it.

abdywgn

dismantler

Do you plan to sell the adapter plates? That speedo gear is quite unique, almost looks worn out. Can't say I remember, but I had a 75 Dart Lite with the OD trans that didn't have a part like that. I enjoy watching your progress!

mygasser

Well-Known Member

or at least scan it (or have it scanned) so it can be replicated if need be.Do you plan to sell the adapter plates?

neil.

-