This is probably common knowledge but was new to me a couple weeks ago. Before you take the hood off your car drill a couple 1/8 inch holes through the hinge and hood a few inches apart. Going back together just get your bolts started and put drill bits through all the holes and tighten the bolts. The hood will be right back where it was originally.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weird tips and tricks

- Thread starter halifaxhops

- Start date

-

Nice!

zigs

Well-Known Member

GOJO hand cleaner (cream style) good degreaser and washes of with water.

famous bob

mopar misfit

drill a hole in the hood ? why not just scribe around the bolt flanges , under the hood ?!?GOJO hand cleaner (cream style) good degreaser and washes of with water.

Here is a good one razor blades for scraping surface rust, try it it works.

goldfish65

Well-Known Member

Ok this goes in the misc file on this thread, not exactly a tip about cars but this is a situation all car guys find ourselves in..lets say you are at a campground or anyplace away from home and you need to take care of your morning post-coffee "business," and you want to get the job done quick...bring a bar of strong-smelling soap (Irish Spring is good) and take some whiffs, the chemical smell triggers whatever it is that makes you go, and you can be on your way!

Best trick yet for removing undercoat a HF scraper!

Alaskan_TA

Well-Known Member

GOJO hand cleaner (cream style) good degreaser and washes of with water.

Related GOJO tip;

If you use it often & develop warts on your hands & fingers, stop using it.

After that episode I switched to the Orange cleaner & no issues, warts went away.

Dartnut

Don't hate me because i'm beautiful

I have a few.

-Want to clean grimy wiring, rubber body plugs etc?

Take an old pillow case and put 'em in and tie a knot in it.

Go to the laundromat and use the ''work clothes only'' washer and put in your favorite detergent and wash it.

The parts will come out as new, and will cost you a buck or two. Don't use it in your own washing machine!

-Have a stubborn crank bolt on your engine and you are trying to get it out in the car? (timing chain change etc.)

Get a 1/2'' or 3/4'' breaker bar with the right sized socket and a length of pipe and secure to the ground under the car.

Turn the engine over with the starter and it will loosen right off.

-When you are removing bolts (especially body bolts) if the bolt starts turning tight, turn it back on a bit and loosen more.

Go back and forth as many times as needed, and eventually it will come off without twisting it off.

-Removing a bearing cup out of a casting and don't need to save it?

Run a bead of weld on the bearing surface of the cup and wait a couple of minutes, and it'll shrink and be easy to remove.

-Remember, heat is your friend when removing stubborn bolts!

Always heat on the casting where the threads surround, not the bolt or stud itself if at all possible.

Again, let it cool off for a minute or so, and it should twist right out.

If not, retry until it does. The idea is that when the casting is heated, it expands and breaks the rust, locktite etc. free and also gives the the hole slightly more size to allow the bolt to turn inside.

-When installing rods onto a crank, use a few inches of vacuum hose on the threads of the bolts to keep from scoring the crank.

-Need to jump start an old car and don't have enough cable for both positive and negative connections?

If the cars have steel bumpers, drive the booster car so that the bumpers are touching.

Hook up the positive cables and start.

The bumpers touching provides the ground. (make sure that the bumpers are touching each other well, or they may arc destroying the chrome on both cars).

And finally i know this from personal experience............

Barrel roll your '70 Dart 4 door in the ditch two times at 60 mph after hitting some black ice in the winter?

The car starts, runs, and drives flawlessly, but you have no windshield? (And it's 10 below)

Drive the car slowly and freeze your butt off.

Orrrrrrrr...........Drive at 50 mph or so and the wind skips off the hood and it's not caught by the huge air scoop that you have created.

It actually was so calm in there that i could light a cigarette.

Obviously, it's not safe to do this, but when you are several miles from civilization, and are freezing to death, desperate times call for desperate measures................

True story, no ****...............

-Want to clean grimy wiring, rubber body plugs etc?

Take an old pillow case and put 'em in and tie a knot in it.

Go to the laundromat and use the ''work clothes only'' washer and put in your favorite detergent and wash it.

The parts will come out as new, and will cost you a buck or two. Don't use it in your own washing machine!

-Have a stubborn crank bolt on your engine and you are trying to get it out in the car? (timing chain change etc.)

Get a 1/2'' or 3/4'' breaker bar with the right sized socket and a length of pipe and secure to the ground under the car.

Turn the engine over with the starter and it will loosen right off.

-When you are removing bolts (especially body bolts) if the bolt starts turning tight, turn it back on a bit and loosen more.

Go back and forth as many times as needed, and eventually it will come off without twisting it off.

-Removing a bearing cup out of a casting and don't need to save it?

Run a bead of weld on the bearing surface of the cup and wait a couple of minutes, and it'll shrink and be easy to remove.

-Remember, heat is your friend when removing stubborn bolts!

Always heat on the casting where the threads surround, not the bolt or stud itself if at all possible.

Again, let it cool off for a minute or so, and it should twist right out.

If not, retry until it does. The idea is that when the casting is heated, it expands and breaks the rust, locktite etc. free and also gives the the hole slightly more size to allow the bolt to turn inside.

-When installing rods onto a crank, use a few inches of vacuum hose on the threads of the bolts to keep from scoring the crank.

-Need to jump start an old car and don't have enough cable for both positive and negative connections?

If the cars have steel bumpers, drive the booster car so that the bumpers are touching.

Hook up the positive cables and start.

The bumpers touching provides the ground. (make sure that the bumpers are touching each other well, or they may arc destroying the chrome on both cars).

And finally i know this from personal experience............

Barrel roll your '70 Dart 4 door in the ditch two times at 60 mph after hitting some black ice in the winter?

The car starts, runs, and drives flawlessly, but you have no windshield? (And it's 10 below)

Drive the car slowly and freeze your butt off.

Orrrrrrrr...........Drive at 50 mph or so and the wind skips off the hood and it's not caught by the huge air scoop that you have created.

It actually was so calm in there that i could light a cigarette.

Obviously, it's not safe to do this, but when you are several miles from civilization, and are freezing to death, desperate times call for desperate measures................

True story, no ****...............

Spray can noodle too short?use 1” of insulation from a 14 or 16 gauge wire to join on another.

Friction modifier bottle is good for many things, i use one with the noodle and insulation to drip sea foam as a penetrating oil. Add a little atf to speed things along.

Friction modifier bottle is good for many things, i use one with the noodle and insulation to drip sea foam as a penetrating oil. Add a little atf to speed things along.

Different colored paint scuffed on your paint?

Mr Clean Magic Erasure and water takes it right off.

Jeff

Mr Clean Magic Erasure and water takes it right off.

Jeff

famous bob

mopar misfit

I have a few.

-Want to clean grimy wiring, rubber body plugs etc?

Take an old pillow case and put 'em in and tie a knot in it.

Go to the laundromat and use the ''work clothes only'' washer and put in your favorite detergent and wash it.

The parts will come out as new, and will cost you a buck or two. Don't use it in your own washing machine!

-Have a stubborn crank bolt on your engine and you are trying to get it out in the car? (timing chain change etc.)

Get a 1/2'' or 3/4'' breaker bar with the right sized socket and a length of pipe and secure to the ground under the car.

Turn the engine over with the starter and it will loosen right off.

-When you are removing bolts (especially body bolts) if the bolt starts turning tight, turn it back on a bit and loosen more.

Go back and forth as many times as needed, and eventually it will come off without twisting it off.

-Removing a bearing cup out of a casting and don't need to save it?

Run a bead of weld on the bearing surface of the cup and wait a couple of minutes, and it'll shrink and be easy to remove.

-Remember, heat is your friend when removing stubborn bolts!

Always heat on the casting where the threads surround, not the bolt or stud itself if at all possible.

Again, let it cool off for a minute or so, and it should twist right out.

If not, retry until it does. The idea is that when the casting is heated, it expands and breaks the rust, locktite etc. free and also gives the the hole slightly more size to allow the bolt to turn inside.

-When installing rods onto a crank, use a few inches of vacuum hose on the threads of the bolts to keep from scoring the crank.

-Need to jump start an old car and don't have enough cable for both positive and negative connections?

If the cars have steel bumpers, drive the booster car so that the bumpers are touching.

Hook up the positive cables and start.

The bumpers touching provides the ground. (make sure that the bumpers are touching each other well, or they may arc destroying the chrome on both cars).

And finally i know this from personal experience............

Barrel roll your '70 Dart 4 door in the ditch two times at 60 mph after hitting some black ice in the winter?

The car starts, runs, and drives flawlessly, but you have no windshield? (And it's 10 below)

Drive the car slowly and freeze your butt off.

Orrrrrrrr...........Drive at 50 mph or so and the wind skips off the hood and it's not caught by the huge air scoop that you have created.

It actually was so calm in there that i could light a cigarette.

Obviously, it's not safe to do this, but when you are several miles from civilization, and are freezing to death, desperate times call for desperate measures................

True story, no ****...............

This reminded me of something that happened when I was 9 yrs old:

Don't run ur ford pick up off a bridge when it is 5 below and the ice is 10-12" thick, going thru, into the water upside down!

We dam near froze to death before we got to the next farmhouse !

Treblig

Well-Known Member

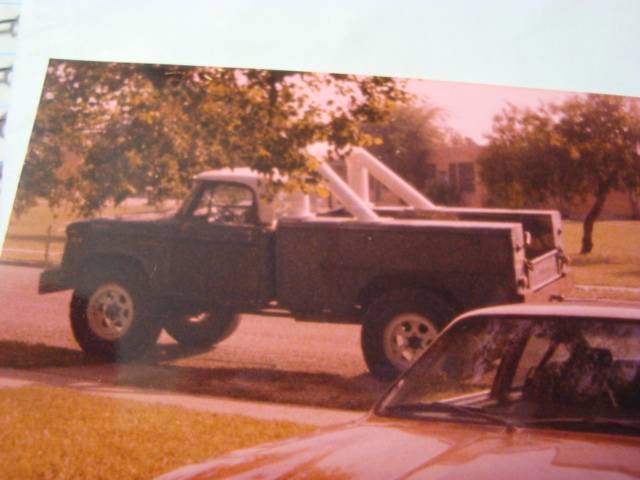

Yes, and don't drive up high into the Rocky Mountains on a sunny day (high 20s temp) to do some four wheeling (68 Dodge Power Wagon) and make the mistake of rolling the truck over, breaking all the glass as the sun starts setting. Then the long drive back to town (1 1/2 hours) as the temperature dropped to 30 below. I had two choices drive slow and slowly freeze to death with the 30 MPH, 30 below wind coming through the windshield OR drive fast (65 MPH) and freeze faster because of the wind chill. Driving faster got me home faster but it also made my body temp decrease faster. The heater was of use at all with a 60 MPH wind coming through the front glass opening. I made it home and went straight to the hospital to get treated for hypothermia. It took 8 hospital employees to keep me from shaking off the gurney as they attempted to remove the tiny glass shards from the broken windshield (that got blown into my eyes) out on eye balls. PS - Yes, I've had an exciting life!!!

Here's the truck after I replaced the top and installed a roll bar!!

Treblig

Here's the truck after I replaced the top and installed a roll bar!!

Treblig

Last edited:

diymirage

HP@idle > hondaHP@redline

Don't run a ford pick up

i think this is great advice

Cope

Fusing with fire

I'm also in the "roll your truck far from home in freezing temps club"... rolled my yota, broke all glass and had to drive home in the snow. Not fun....

Treblig

Well-Known Member

Man!! If it had been snowing I don't think I would have made it?? Luckily it was a clear, cold winter day. But being from S. Texas I had no idea how much the temperature can drop once the sun goes away!! I was at about 7500ft when I rolled the truck, had to drive down to 6000 feet (Cheyenne Wy.) I grew up in S. Texas so I couldn't handle the cold at all, especially in a 60 MPH wind???I'm also in the "roll your truck far from home in freezing temps club"... rolled my yota, broke all glass and had to drive home in the snow. Not fun....

Dartnut

Don't hate me because i'm beautiful

Here's a few pics of the '70 Dart that i rolled.

I rolled it twice, and on the second roll i heard a ''pop'' and the windshield came out.

It landed on it's wheels.

Also, it was a 56,000 mile car with mostly original paint and virtually no rust.

I took the 318 and trans with all of the suspension (i converted it to bbp discs etc. beforehand) and put it all in my '69 Valiant 2 door. I parted out the rest and sold the carcass to a friend of mine restoring a '70 340 Swinger.

Here's another tip:

Don't throw away or junk anything.

It's amazing what you can later use off of a parts car that you never thought of at the time you were parting it out.

For example, over 90% of what was left of this car will be reused to save others.

I rolled it twice, and on the second roll i heard a ''pop'' and the windshield came out.

It landed on it's wheels.

Also, it was a 56,000 mile car with mostly original paint and virtually no rust.

I took the 318 and trans with all of the suspension (i converted it to bbp discs etc. beforehand) and put it all in my '69 Valiant 2 door. I parted out the rest and sold the carcass to a friend of mine restoring a '70 340 Swinger.

Here's another tip:

Don't throw away or junk anything.

It's amazing what you can later use off of a parts car that you never thought of at the time you were parting it out.

For example, over 90% of what was left of this car will be reused to save others.

famous bob

mopar misfit

i think this is great advice

LOL

Ddaddy

I'm changing the World... one pixel at a time!

Here’s one we used recently to install the new rubber boots on a new set of torsion bars.

Create a stack of sockets with the smallest being the size of the opening of the boot and the largest being the diameter of the hex head end of the torsion bar. Run a long bolt through the middle of the socket stack and secure with a nut to hold the stack rigid. Then lube the boot and work slowly from one socket to the next until it reaches the largest size. Then place it against the hex head end of the t-bar and pull it over.

By slowly moving from one size socket to the next, the boot doesn’t get over stretched and rip.

Was very easy to do and worked like a charm.

Create a stack of sockets with the smallest being the size of the opening of the boot and the largest being the diameter of the hex head end of the torsion bar. Run a long bolt through the middle of the socket stack and secure with a nut to hold the stack rigid. Then lube the boot and work slowly from one socket to the next until it reaches the largest size. Then place it against the hex head end of the t-bar and pull it over.

By slowly moving from one size socket to the next, the boot doesn’t get over stretched and rip.

Was very easy to do and worked like a charm.

-