Drove up to the Kroger and filled up with Rec90 and hammered it all the way and back. Last show of the year this weekend and damn its time to put it away and get started on those Christmas lights!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Are You Doing To/With Your Car Today?

- Thread starter MobileCustoms

- Start date

-

Better start untangling them now if you want them up by Christmas!Drove up to the Kroger and filled up with Rec90 and hammered it all the way and back. Last show of the year this weekend and damn its time to put it away and get started on those Christmas lights!

Jeff

Better start untangling them now if you want them up by Christmas!

Jeff

They were put away correctly but at 25k or more it takes lots of time to get them all up! The wife wants lights on T-Giving night right after dinner! Course the string I left up on the neighbors shed would classify as “Lights”.

What did I do with my car today? Nothing more than checking on a intake I bought.

lgjhn

"The faster you go, the faster you go..."

Finished blasting my rotors and calipers yesterday before the rain moved in here.

Put a little paint on em...not so much for good looks but to keep em from rusting back up.

Today, I'm inside the shop cleaning up the rotor internals and adding new bearings/seals. Then, on to rebuilding the calipers with new seals, hoses, etc.

Need to get her back to "roller status" so I can get her outside where I can start prepping for paint.

Put a little paint on em...not so much for good looks but to keep em from rusting back up.

Today, I'm inside the shop cleaning up the rotor internals and adding new bearings/seals. Then, on to rebuilding the calipers with new seals, hoses, etc.

Need to get her back to "roller status" so I can get her outside where I can start prepping for paint.

JeffisOld

Old, Ugly and generally Disagreeable!

Completely removed the original front suspension today!

Tomorrow I will do some clean up and lay down some primer for a clean mounting surface. I have an RMS Alternation to mount up in the next two days. The engine compartment needs a complete mock up so I can plan my routing of wires and lines which will most likely differ with the 512 vs the original 273 engine. Holes to fill, and new ones to make. Battery going to the trunk, etc!

What a BLAST!

Tomorrow I will do some clean up and lay down some primer for a clean mounting surface. I have an RMS Alternation to mount up in the next two days. The engine compartment needs a complete mock up so I can plan my routing of wires and lines which will most likely differ with the 512 vs the original 273 engine. Holes to fill, and new ones to make. Battery going to the trunk, etc!

What a BLAST!

Last edited:

skep419

5.9 Magnum 4 speed afficionado

ddartdude

Well-Known Member

Replaced the mini starter and starter relay in the D/Dart. Could only find a relay for an automatic so I used it. Just grounded the extra terminal.

I mounted 2 REAL NICE used 235 60 14 Goodrich tires on 2 of the wheels I recently painted for RobKat.

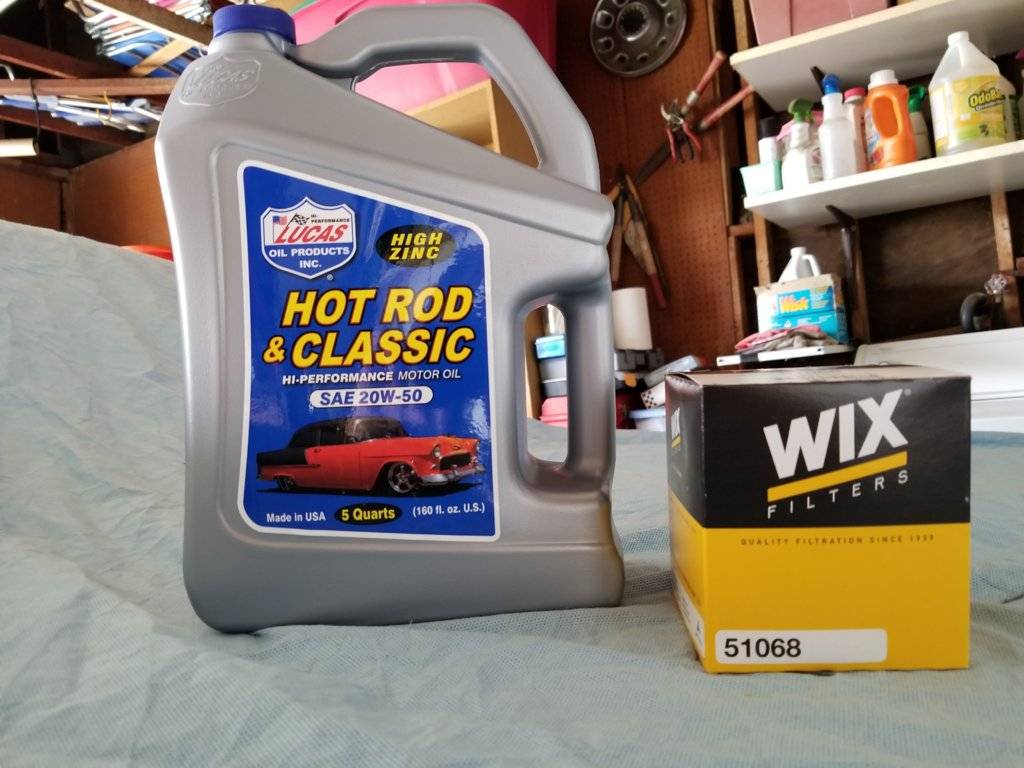

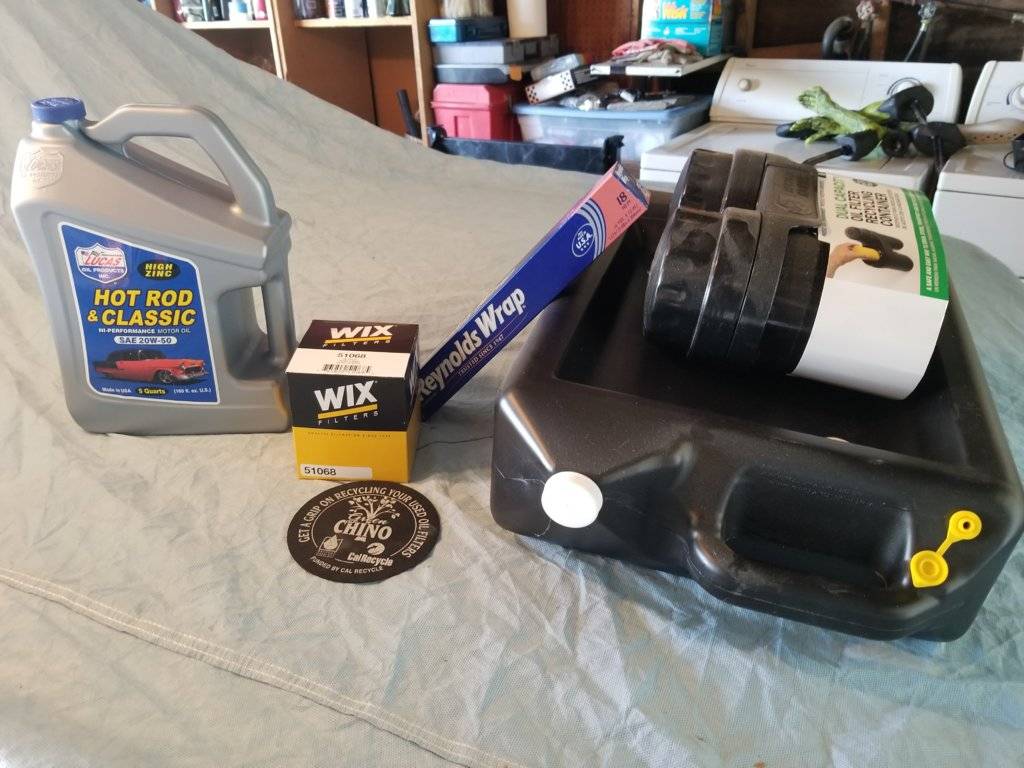

Oil change yesterday. ..woohoo!

She's happy now!

Jeff

She's happy now!

Jeff

JeffisOld

Old, Ugly and generally Disagreeable!

Well, temporarily mounted the "K" frame, more like a "C" frame for the RMS front end. It will have to come out again to finish cleaning and paint. Got my ***-whooped by the lower bump stop removal also. Now I have holes to weld too.

Besides I am dying to put it together long enough to put the wheels and tires and see how the stance will be adjustable. I've never seen a 69 Dart with:

18 x 10 rear wheels with 295/45R18 rubber

16 x 7 wheels on the fronts with 205/50R16 rubber

Besides I am dying to put it together long enough to put the wheels and tires and see how the stance will be adjustable. I've never seen a 69 Dart with:

18 x 10 rear wheels with 295/45R18 rubber

16 x 7 wheels on the fronts with 205/50R16 rubber

Went to our last car show this year and took home another award, bit foggey this morning with lots of water on the car and thwarted the rain this afternoon.

Best deal is a friend with his 440 duster finally scored an award, it is a “really” nice car that somehow has not got the recognition it deserves!

Anyhow we got two awards the other brands did not! Go Mopar!

Best deal is a friend with his 440 duster finally scored an award, it is a “really” nice car that somehow has not got the recognition it deserves!

Anyhow we got two awards the other brands did not! Go Mopar!

Last edited:

I’m looking forward to seeing that! I’m planning on putting 295/45/18s on the back of my Duster.Well, temporarily mounted the "K" frame, more like a "C" frame for the RMS front end. It will have to come out again to finish cleaning and paint. Got my ***-whooped by the lower bump stop removal also. Now I have holes to weld too.

Besides I am dying to put it together long enough to put the wheels and tires and see how the stance will be adjustable. I've never seen a 69 Dart with:

18 x 10 rear wheels with 295/45R18 rubber

16 x 7 wheels on the fronts with 205/50R16 rubber

Went to our last car show this year and took home another award, bit foggey this morning with lots of water on the car and thwarted the rain this afternoon.

Best deal is a friend with his 440 duster finally scored an award, it is a “really” nice car that somehow has not got the recognition it deserves!

Anyhow we got two awards the other brands did not! Go Mopar!

View attachment 1715107410

I should add that this show was participant only voting with about 170 cars and 17 classes. So to get 2 A body Mopars awarded is difficult at best. Bad thing is the other brands in our classes after hearing results all left revving their engines as soon as the results were announced. What the F, could they not wait and clap for all the other class winners? Spoiled rotten other brands hate to loose, Why we Mopar guys humbly wait and clap for all! Win or not we stay and honor the others. Love the diehard Mopar guys!

moper

Well-Known Member

Gut the plow truck's wiper linkage re-bushed - reinstalled it. Now it has no wipers at all. It had low speed prior to the linkage being removed... sigh... Must need a motor. I wish I knew if the variable speed piece was part of the motor. The relay clicks so it's got to be the motor.

Switched gears to the LHS and spent 3 hours replacing one rear strut. Car is really clean, but man is the suspension rusted together. Torches, torches, and more torches to get it apart. At least the second side will go a lot faster now that I know what the speed bumps are.

Switched gears to the LHS and spent 3 hours replacing one rear strut. Car is really clean, but man is the suspension rusted together. Torches, torches, and more torches to get it apart. At least the second side will go a lot faster now that I know what the speed bumps are.

JeffisOld

Old, Ugly and generally Disagreeable!

Cleaned up and primed the area where the K frame used to mount. Hung the Alternation cross member and drilled the required bolt holes. Installed hardware, lower tubular control arms and the front coil-overs on both sides. Put upper control arm on passenger side and I took absolutely no pictures.

Guess I need to remember that now huh!

Guess I need to remember that now huh!

You’ve been on this forum for 4 months and you still haven’t learned that...Cleaned up and primed the area where the K frame used to mount. Hung the Alternation cross member and drilled the required bolt holes. Installed hardware, lower tubular control arms and the front coil-overs on both sides. Put upper control arm on passenger side and I took absolutely no pictures.

Guess I need to remember that now huh!

lgjhn

"The faster you go, the faster you go..."

Continued working on the brakes for my '73 Dart Sport. Finally got the pistons out of the calipers....whadda job!!!

Tried everything, including compressed air...yeah, I know...dangerous. Used penetrant oil to try and loosen and lube the internal seal a little.

I almost gave up and was thinking of just ordering new ones from RockAuto, but I decided to give it one more good shot: I loaded up my grease gun with a fresh tube of grease and put a rubber tip on it. Made sure the bleeder was closed, crammed the rubber tip into the threaded hose connection and pumped the grease to her while tightly holding the rubber tip in there....viola!!! The piston moved on out to about the last 1/4" or so. Some gentle taps with a hammer and punch around the outside edges and they were out.

This method cost me about 3/4 of a tube of grease but it was worth it to get em on out.

Pistons looked great and no serious pitting in the cylinders!!! I was pretty concerned since they've been sitting in the shop for over 17 years...LOL

Glass bead-blasted the internals clean, including the seal slots, etc. Washed everything completely spotless with brake cleaner. Made sure the piston fit without the seal first.

All was good and assembled with new seals using a tad of silicone grease for lubricant. Got one completely rebuilt and ready to install on the car. I should have the other one ready to go by lunchtime tomorrow. Getting this old gal back to roller status has been a chore....but I love it.

Tried everything, including compressed air...yeah, I know...dangerous. Used penetrant oil to try and loosen and lube the internal seal a little.

I almost gave up and was thinking of just ordering new ones from RockAuto, but I decided to give it one more good shot: I loaded up my grease gun with a fresh tube of grease and put a rubber tip on it. Made sure the bleeder was closed, crammed the rubber tip into the threaded hose connection and pumped the grease to her while tightly holding the rubber tip in there....viola!!! The piston moved on out to about the last 1/4" or so. Some gentle taps with a hammer and punch around the outside edges and they were out.

This method cost me about 3/4 of a tube of grease but it was worth it to get em on out.

Pistons looked great and no serious pitting in the cylinders!!! I was pretty concerned since they've been sitting in the shop for over 17 years...LOL

Glass bead-blasted the internals clean, including the seal slots, etc. Washed everything completely spotless with brake cleaner. Made sure the piston fit without the seal first.

All was good and assembled with new seals using a tad of silicone grease for lubricant. Got one completely rebuilt and ready to install on the car. I should have the other one ready to go by lunchtime tomorrow. Getting this old gal back to roller status has been a chore....but I love it.

chryslerfat

Well-Known Member

The grease trick also can work to free up a stuck engine.Continued working on the brakes for my '73 Dart Sport. Finally got the pistons out of the calipers....whadda job!!!

Tried everything, including compressed air...yeah, I know...dangerous. Used penetrant oil to try and loosen and lube the internal seal a little.

I almost gave up and was thinking of just ordering new ones from RockAuto, but I decided to give it one more good shot: I loaded up my grease gun with a fresh tube of grease and put a rubber tip on it. Made sure the bleeder was closed, crammed the rubber tip into the threaded hose connection and pumped the grease to her while tightly holding the rubber tip in there....viola!!! The piston moved on out to about the last 1/4" or so. Some gentle taps with a hammer and punch around the outside edges and they were out.

This method cost me about 3/4 of a tube of grease but it was worth it to get em on out.

Pistons looked great and no serious pitting in the cylinders!!! I was pretty concerned since they've been sitting in the shop for over 17 years...LOL

Glass bead-blasted the internals clean, including the seal slots, etc. Washed everything completely spotless with brake cleaner. Made sure the piston fit without the seal first.

All was good and assembled with new seals using a tad of silicone grease for lubricant. Got one completely rebuilt and ready to install on the car. I should have the other one ready to go by lunchtime tomorrow. Getting this old gal back to roller status has been a chore....but I love it.

Painted the car last month, now for the daunting task of wet sanding and buffing. This is my practice car, if I can make it at least a “five footer” the Dart that I have will be next. I told my two daughters, that I would build them each a car. The youngest wanted an older stang, The oldest said, “Dad, build me something that you would want”. Ding, ding, ding, correct answer, Mopar Muscle. The bad thing about this I started on the stang first........but I am enjoying driving the Dart for now.

DustyDuster

Imfamous member

You're going to need a bigger tube for that trick to work!The grease trick also can work to free up a stuck engine.

chryslerfat

Well-Known Member

It`s not the size of the tube that makes it turn. Take an old spark plug and weld a grease fitting to it then just pump away.You're going to need a bigger tube for that trick to work!

-