FABO Friends,

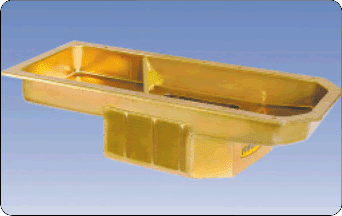

Hoping someone can give me a PN or an application for a HARD TUBE and dipstick for a Gen III Hemi, VVT block, mid sump swap pan...with Headers, such as the one pictured below.

I've ordered in probably a dozen aftermarket, and OE tubes, and they ALL hit the headers besides the holley (which has the mounting tab welded on in the completely wrong position)

The braided flex ones i'm not a fan of, and the 3 i have tried are very poor fitting, and the wrong length.

looking to provide a hard tube on this engine, which we eventually just produce in house, but I need to have one that fits before we get to that point!

our block is a new hellcat BGE block. pretty sure this would have to be a 2009+ VVT stick. pretty sure the earlier engines are different.

Note the one in the picture below is close, but the tab is the wrong height, and we can't take the time to cut/weld 1000 dipsticks a year until we have our own.

THANK YOU ALL in advance if you can provide me with a solution.

Hoping someone can give me a PN or an application for a HARD TUBE and dipstick for a Gen III Hemi, VVT block, mid sump swap pan...with Headers, such as the one pictured below.

I've ordered in probably a dozen aftermarket, and OE tubes, and they ALL hit the headers besides the holley (which has the mounting tab welded on in the completely wrong position)

The braided flex ones i'm not a fan of, and the 3 i have tried are very poor fitting, and the wrong length.

looking to provide a hard tube on this engine, which we eventually just produce in house, but I need to have one that fits before we get to that point!

our block is a new hellcat BGE block. pretty sure this would have to be a 2009+ VVT stick. pretty sure the earlier engines are different.

Note the one in the picture below is close, but the tab is the wrong height, and we can't take the time to cut/weld 1000 dipsticks a year until we have our own.

THANK YOU ALL in advance if you can provide me with a solution.