Drive shaft angle doesn’t come into play on a car. If u have a jacked up 4x4 then they sure do. KimThese Driveshaft angles are like talking camshaft grinds with people . . .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vibration right off idle

- Thread starter plumkrazee70

- Start date

-

512Stroker

We are all here because we are not all there.

I never had an issue with mine until I installed a new set of ESPO springs, moved the pinion angle almost 2* negative. I had to install a 2* shim between the spring and the perch to correct it.Ok... So how did that happen? It's a factory 8.75 with espo springs and things 6 leaf springs. I never changes the perches...

plumkrazee70

Well-Known Member

I never had an issue with mine until I installed a new set of ESPO springs, moved the pinion angle almost 2* negative. I had to install a 2* shim between the spring and the perch to correct it.

Oh interesting. I'll re measure and write them down. I guess I was trusting the app. I'm gonna leave the trans where it is and move the pinion accordingly.

plumkrazee70

Well-Known Member

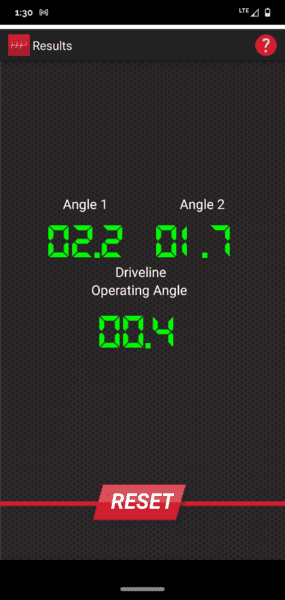

Ok, I re measured. Here is the approach I took and a recap.

I put an OD trans in my car and it has changed the driveline angle.

What I have is:

Trans: 2.5* down

Pinion: 1.5* down

So if I want to make the two angles parallel at rest, I need to add a 4* shim to the pinion, resulting in 2.5* up at the pinion.

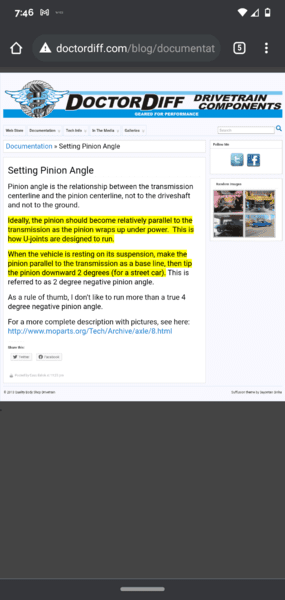

Cass (Dr. diff) wrote on his website that you want the pinion parallel with trans and then roll the pinion down 2 degrees for a street car.

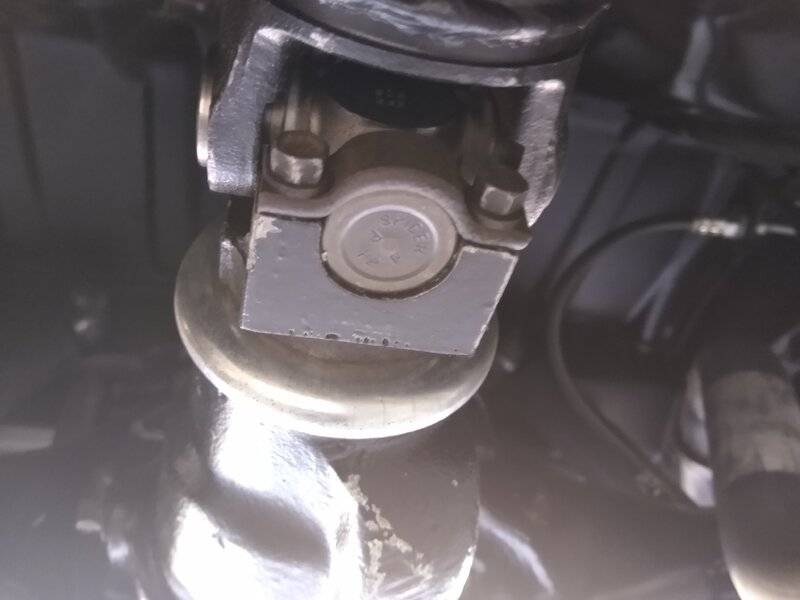

I measured the angles with the car on its wheels on the floor. The trans was taken at the tail shaft and the the pinion was taken at the yoke surface (pic attached)

What's interesting is that the Tremec app says, I'm good. Thanks for your help.

Mike

I put an OD trans in my car and it has changed the driveline angle.

What I have is:

Trans: 2.5* down

Pinion: 1.5* down

So if I want to make the two angles parallel at rest, I need to add a 4* shim to the pinion, resulting in 2.5* up at the pinion.

Cass (Dr. diff) wrote on his website that you want the pinion parallel with trans and then roll the pinion down 2 degrees for a street car.

I measured the angles with the car on its wheels on the floor. The trans was taken at the tail shaft and the the pinion was taken at the yoke surface (pic attached)

What's interesting is that the Tremec app says, I'm good. Thanks for your help.

Mike

No no no. The pinion needs to be lower than the trans angle by atleast 2.5*. U went the wrong way. Kim

plumkrazee70

Well-Known Member

No no no. The pinion needs to be lower than the trans angle by atleast 2.5*. U went the wrong way. Kim

Ok, but if the trans angle doesn't allow that then what?

I thought the bottom line was the trans and pinion need to be parallel? Trans -2.5 and pinion +2.5 ( those would be parallel)

Then roll the pinion down 2*.

I emailed Cass the same thread and he agreed with me, so I'm confused.

512Stroker

We are all here because we are not all there.

You are lostOk, but if the trans angle doesn't allow that then what?

I thought the bottom line was the trans and pinion need to be parallel? Trans -2.5 and pinion +2.5 ( those would be parallel)

Then roll the pinion down 2*.

I emailed Cass the same thread and he agreed with me, so I'm confused.

Listen

The trans output shaft MUST POINT UP or positive

The rear end pinion yoke MUST POINT DOWN or negative

This is not rocket surgery you are over thinking this.

Dartswinger70

Well-Known Member

It's the wheel hop from the rear wheels gyrating out of control...

Phreakish

Well-Known Member

I have never seen the output shaft on a car or truck point upward (toward the sky).

@plumkrazee70 has it correct. 2 degrees down from parallel may be too much though if the front half of the springs are super stiff. I'd try it with the pinion at parallel and at 1 Deg down from parallel just to see how it runs.

Could also be that the vibration is from the engine and when the OD kicks in, the revs drop and the vibration goes away. Could be in the trans too, but I wouldn't know where to start looking for that.

@plumkrazee70 has it correct. 2 degrees down from parallel may be too much though if the front half of the springs are super stiff. I'd try it with the pinion at parallel and at 1 Deg down from parallel just to see how it runs.

Could also be that the vibration is from the engine and when the OD kicks in, the revs drop and the vibration goes away. Could be in the trans too, but I wouldn't know where to start looking for that.

512Stroker

We are all here because we are not all there.

Dude have you ever physically measured one? I use a digital meter and believe me they point up, I am not trying to bullshit the OP or you.I have never seen the output shaft on a car or truck point upward (toward the sky).

@plumkrazee70 has it correct. 2 degrees down from parallel may be too much though if the front half of the springs are super stiff. I'd try it with the pinion at parallel and at 1 Deg down from parallel just to see how it runs.

Could also be that the vibration is from the engine and when the OD kicks in, the revs drop and the vibration goes away. Could be in the trans too, but I wouldn't know where to start looking for that.

The ONLY way you are going to make a driveshaft run vibration free is to have offsetting angles that equal 0* that makes it run parallel. The differential has to point down as it will move up as torque is applied to the rear springs, therefore the trans output must point up to offset the downward angle of the diffy. This is not difficult to understand there a dozens of online articles and videos that prove this out.

I agree that the OP has other issues that may be causing his vibration but if the shaft angles are not right is will shake.

I am out, again

Phreakish

Well-Known Member

Dude have you ever physically measured one? I use a digital meter and believe me they point up, I am not trying to bullshit the OP or you.

The ONLY way you are going to make a driveshaft run vibration free is to have offsetting angles that equal 0* that makes it run parallel. The differential has to point down as it will move up as torque is applied to the rear springs, therefore the trans output must point up to offset the downward angle of the diffy. This is not difficult to understand there a dozens of online articles and videos that prove this out.

I agree that the OP has other issues that may be causing his vibration but if the shaft angles are not right is will shake.

I am out, again

I've only measured a few dozen. All of them point down. Intake manifolds are slanted too in order to compensate for the engine and transmission angle... I can't imagine how I could get the trans output to point up, my shifter would hit the floor.

Dartswinger70

Well-Known Member

I remember welding the spring perches on a rear in a Dart. We used an angle gauge on the rear center section to set it before we tacked it. Indent recall the actual angle we used though. It wasn't parallel to the ground

plumkrazee70

Well-Known Member

@512Stroker I understand what you're way by, but the trans CANNOT go any higher. Besides, I don't think the driveline CARES whether one is up or down, as long the pinion and trans output are PARALLEL.

I've already talked to Dr. Diff to get his opinion and he verified I was correct. So I think I got my answer

I've already talked to Dr. Diff to get his opinion and he verified I was correct. So I think I got my answer

512Stroker

We are all here because we are not all there.

Good luck@512Stroker I understand what you're way by, but the trans CANNOT go any higher. Besides, I don't think the driveline CARES whether one is up or down, as long the pinion and trans output are PARALLEL.

I've already talked to Dr. Diff to get his opinion and he verified I was correct. So I think I got my answer

Let us know how that works for ya.

512Stroker

We are all here because we are not all there.

I believe yaI've only measured a few dozen. All of them point down. Intake manifolds are slanted too in order to compensate for the engine and transmission angle... I can't imagine how I could get the trans output to point up, my shifter would hit the floor.

I have set up 4 cars, 3 Mopars, like this in the last couple years. In all 4 cases the trans output shaft pointed up 1.5* - 2.0* - no vibration.

I still think the OP has other issues.

This is the exact reason I will not be installing a n A518 in my rig as I do not want to modify the tunnel and cross member to make it right.

No matter where your trans tail shaft angle is your pinion has to be at least 2* lower than the trans. Your pinion and trans angle is only parallel when your getting on it. Not when your cruising. You need the difference so the u joints can operate. Kim

plumkrazee70

Well-Known Member

Right. Is that not what I've been saying? Dr. Diff says it pretty plain and this is what I am planning.

Setting Pinion Angle - Quality Body Shop Drivetrain.

Setting Pinion Angle - Quality Body Shop Drivetrain.

-