You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1968 Barracuda Notch 340

- Thread starter I8NEMO

- Start date

-

I decided to go with the E body ends on front bumper. Spent quite a bit of time adjusting the bumper position and massaging steel before any tacking began, including minor valance surgery. Top rail on the bumper return end gets a filler piece ( silver painted template in pick) I've learned that custom work is usually a series of compromises, especially on older cars. Im capable but Im no Chip Foose. Im happy with this.

mygasser

Well-Known Member

that little infill piece makes all the difference, it works now

neil.

neil.

Yesterday, with a plan already in place the passenger side bumper end fit up was easy. Im stretched pretty thin with several projects but it feels good. I started a spiral shower out by our jacuzzi, jacuzzi needs new side panels and cover. Im going with old pallets for the side boards I'd been saving. In about an hour I had the 24 linear board feet I needed saws all'd off the pallet frames and cut to length. Spiral shower walls will curve up to about 7 feet where I'll have a waterfall fixture/ pot for the shower head. Im laying in old pipe for this " cannon fire" thing I did with the jacuzzi walls and continued off the existing jacuzzi wall for continuity. Ishould have split the 8x8s but oh well. My youngest did his first oil change on his first car , wife has new carpet picked out and ive got 1200 sf of veneer pavers waiting to go down from back doors out to bbq surround.

Finished fitting the passenger side bumper return and was sharing pics with a talented young metal worker and he asked if I wanted the bumper TIG welded and blended so I said sure. $150 to weld and blend both ends. Amazing work.

mygasser

Well-Known Member

ooh, now that's more like it. nice job

neil.

neil.

I took a couple hours putting the bumper and brackets back on. I did this as if the car was painted kinda for practice since the bracket and bumper mods put everything much closer. It appears this bumper tuck is finally behind me. Was eyeballing the rear bumper recently which ive already tucked to rear of car via bracket mod but I didn't shorten it to bring the returns in, looks like that's next. Always something right? Looking ahead for what's next i think i really want to drive it before it goes back on the rotisserie. I need a clutch, install brake lines and a fuel tank. Today, this project finishing feels far far away, but that will change as it always does. Pic shows bumper tuck complete and driver side valance surgery complete

Brake hard lines done. Gear box is out, ordered a clutch and correct pilot bushing. After brakes and clutch are finished it's fuel tank and lines.

Took 2 weeks away from the Cuda, burned out from all the rabbit holes on what I thought were simple issues; like a friggin pilot bushing. A .94 was too fat and so was the .915 bushing I found on e- bay. Inside calipers I bought only measured in 100ths. So reached out to my buddy Austin, smart talented 23 year old kid ready to graduate and getting offers from aerospace companies. He said he'd be glad to make a new bushing from scratch, he bought a pin gauge set he's always wanted and measured the crank bore, had a bushing turned out in a day for me. Bushings in the freezer, maybe I get back to Cuda work today.

- Joined

- Mar 17, 2018

- Messages

- 15,217

- Reaction score

- 35,905

I just love the creativity on your build. Keep going it looks great!

Bushing is in. At room temp. the bushing slid over the input shaft nicely, Glad I had the hunk of brass round stock, took a bit more whacking than I anticipated. The i.d. of the bushing also provides for slight compression once inserted according to Austin.

Thanks much for the incentive, I needed that!I just love the creativity on your build. Keep going it looks great!

Keith Mopar

Mopar Nut

Wow that front bumper looks incredible.

Better than Chip could do!!!

Better than Chip could do!!!

Ever stuff a tranny in and forget the T.O. bearing? I did. The only reason I did I believe, is because I did it once before intentionally to have the trans in only for support of the engine with no clutch or t.o. bearing. Even after telling myself 100 times, don't forget the T.O. bearing. Even after laying out all the parts in order. Hilarious. It took only about 30 minutes more to back out the trans/slip in the fork/bearing, good practice. Jesus last night I locked my keys and wallet in the truck overnight, first time ever. So the tranny slid in and needed nudging via the mounting bolts for the final 3/4" of the way. I'm not chalking this up to pilot bushing or clutch alignment because the exact circumstances were experienced when I installed the tranny with no clutch or bearing. I then went to the parts bin, pulled out my Hurst shifter I rebuilt idk a year or 2 ago, handle, knob, boot, linkage rods. So nice when that stuff is done ahead of time and all I gotta do is unbag nice clean parts. It's looking like the only ugliness left is the car body itself. Really good to see a stick through the floor again! Got a new fuel tank on the way, new U joints going in drive line. Back to brakes next I believe, the braided stainless flex hoses that came with the front spindle kit sure are unforgiving, they need to be installed and then fill master and bleed, going with silicone brake fluid fingers crossed. Check out the before shifter pics from July 2015. Yeah, yesterday was a red letter day aside from struggling with Hursts replacement linkage clips, holy hell impossible!.

Dodge Metallic Gray is one of the body colors ive got in mind and have envisioned it on the rear axle for a long time so decided to paint it, looks good. The small pinion 3rd member is temporary, still, can't put filthy parts back on so it got a cleaning and some black. The car came with a bench seat, I later discovered it was built with buckets. I filled the previous owners seat holes and a friend gave me these 2 buckets a few years back. One step closer to test driving

Got the fuel tank rattled black. Cleaned up straps then a quick coat of clear. For now,Im giving coroplast a shot for tank top protection, used spray adhesive and Gorilla tape to hold it down and also to protect tank to strap interface. Cleaned up other parts, filler tube got weld nuts and machine screws in keeping with my extermination of all sheet metal screws possible. Im in the coatings business so mixed up some chemical resistant Novolac epoxy and soaked the inside of the filler tube to lock down any rust. Tomorrow my shop manager and I will lower the tank a bit and install the filler tube and fill cap. Feeling good about the progress

Last edited:

Trunk grommet and torque strap landed. Fuel tank and filler tube are in. Got a snag I think, with the master cylinder, was cleaning it to prep for the switch to DOT 5, and not sure about the forward spring and retainer that fits neither end of the spring. My overall plan for a fuel tank is/was in the spare well, I love a good look at a car's differential and didn't want it obscured by the tank but I actually like this look showing less shock. I'll probably run fuel line tomorrow. Test drive list is shrinking nicely.

mygasser

Well-Known Member

you know the easy way to show less shock is to paint them the same colour as the axle?

Ha, yeah, that may very well happenyou know the easy way to show less shock is to paint them the same colour as the axle?

Master cylinder bench bled and back in after cleaning DOT 4, and solving the secondary spring and retainer mystery. Door latches in, side mirrors on for fun ( passenger side was not factory, I added for symmetry) all brake fittings re checked. P/S pump was exhumed for brackets, picked up a new one on the way home at NAPA. Pressure side hose looks good after cleaning so going with it. Brackets wheeled and painted.

New p/s pump in. Power steering hose from factory pump to Borgeson box made up. Took 2 attempts, i did not notice the depth of the pressure side box inlet hole so the standard male double flare cannot seat before the threads are buried. So I pulled out the included adapter from Borgeson which required a female end on the hose requiring the second hose attempt. the good guys at Hose Power did the second hose for free. Front caliper to flex hose connection leaked horribly without any pressure input. The calipers came with wider seal washers and the hose kit came with narrower seal washers. The wider washers leaked, put the skinnies in and all good.

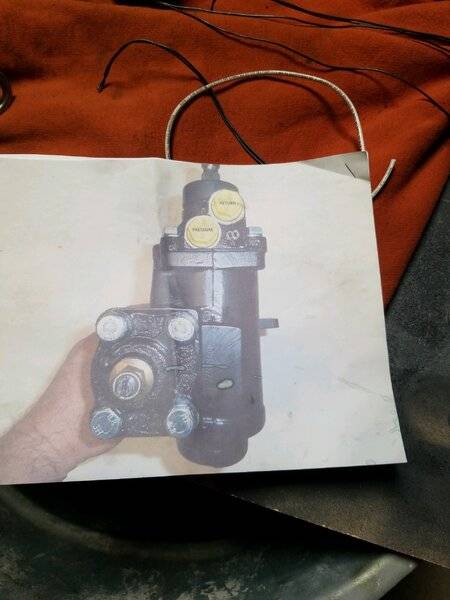

Fired the motor yesterday morning with power steering in for the first time and the wheel shook violently back and forth in my hand. All I could do was smirk, drop my head and shut it off, I knew I had made a mistake instantly. So even with a printed picture showing pressure and return I most certainly had the hoses bass ackwards. Off to buy a Turkey baster. Thankful the inlet fittings are identical, used the baster and some strategy to minimize the fluid mess and got the hoses switched, bled, and fired up this angry little 340. All appears well.

As for the front caliper leak, I remembered the d.b. kit came with large copper seal washers, the braided flex hose kit had much narrower seals I flipped a coin at the time and used the fatties. Decided to switch in the skinnier washers and hello! Leak gone.

As for the front caliper leak, I remembered the d.b. kit came with large copper seal washers, the braided flex hose kit had much narrower seals I flipped a coin at the time and used the fatties. Decided to switch in the skinnier washers and hello! Leak gone.

Didn't have a warm body to help bleed brakes so decided to fab in the centering bolts that will keep exhaust tips centered in the valance. Due to accessibility I put put 2 bolts near the bottom, and 1 bolt through the top that will be adjustable through a 3/8" hole in the trunk floor with a body plug. The original valance work was done using 1/8" pieces of steel tacked to tips to center seen in the pic showing exhaust tips on.

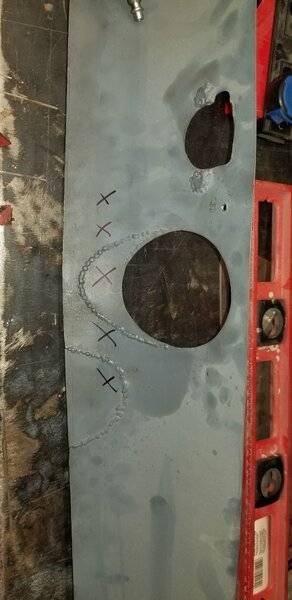

Front monroe shocks showed up yesterday so those will go on soon. Here's a finished pic of the through trunk top adjuster for the exhaust tips. Actual hardware will be headless slotted studs below the trunk floor covered via body plugs. Now ive gotta hammer out an issue in the rear valance where it had been smacked at some point before my ownership. Ther left side needs more curvature where ive marked with x's

-