Swinger340Canuc

72 Swinger 340 Special

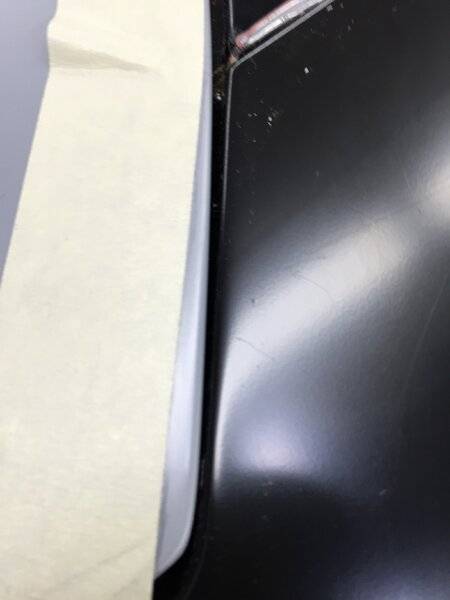

Had to do a bit of painting to repair the area on the tub where I had to bring the lip down to meet the tub so that spot-in needed to be done first,

A problem that gave me a headache for quite some time was my trunk gap at the corners was tight and there was no way to move the quarters ahead anymore and even if I could it would mess up the alignment at the back. All the gaps are good except at this point and the fact that the quarters are an 1/8th inch short might have something to do with it but I wasted enough time puzzling over this and decided the best solution was to shave the corners of the trunk lid and weld them up and think it looks fine.

Sound deadener from Rick's Restoration needs to go on next then I can get some paint on the inside,

Next is to get all the holes where i'm going to plug weld drilled and all the surfaces taken down to bare metal and the matching surfaces on the car itself as well and weld thru primer applied.

All ready to go for welding in place just need to get some more panel bonding adhesive for the small area were the rear cowl and corner of the window channel and quarter come together, a near impossible spot to get at to weld so this works great and assures a water tight joint.

A problem that gave me a headache for quite some time was my trunk gap at the corners was tight and there was no way to move the quarters ahead anymore and even if I could it would mess up the alignment at the back. All the gaps are good except at this point and the fact that the quarters are an 1/8th inch short might have something to do with it but I wasted enough time puzzling over this and decided the best solution was to shave the corners of the trunk lid and weld them up and think it looks fine.

Sound deadener from Rick's Restoration needs to go on next then I can get some paint on the inside,

Next is to get all the holes where i'm going to plug weld drilled and all the surfaces taken down to bare metal and the matching surfaces on the car itself as well and weld thru primer applied.

All ready to go for welding in place just need to get some more panel bonding adhesive for the small area were the rear cowl and corner of the window channel and quarter come together, a near impossible spot to get at to weld so this works great and assures a water tight joint.

Last edited: