Dustin The PcP

Well-Known Member

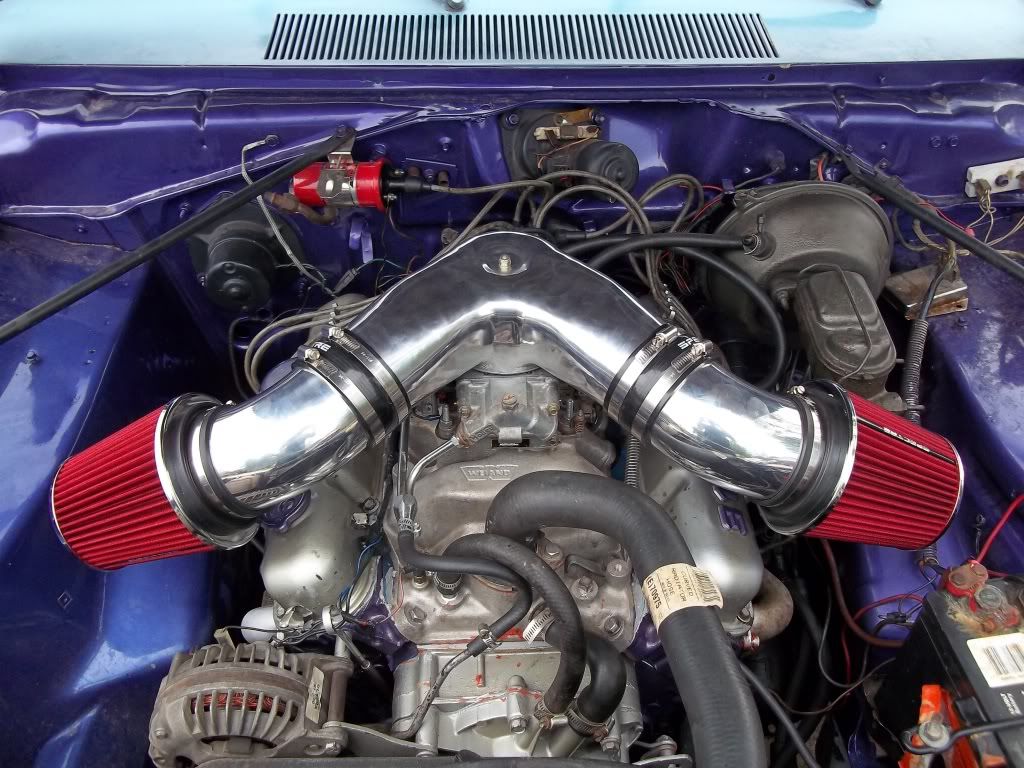

Well I went up to work today to try and put my new rear shocks on, but ended up not being able to. The diameter of the bushing hole was to small, so I am sending them back, and hoping to get the right ones this time! But here is a little bit of what I have to do for the suspension =)!

Front sway bar 1" diameter, Rear sway bar 7/8" diameter, Traction bars, Coil over shocks with 1200lb springs, and I just added some edelbrock classic IAS shocks to the front.

Front sway bar 1" diameter, Rear sway bar 7/8" diameter, Traction bars, Coil over shocks with 1200lb springs, and I just added some edelbrock classic IAS shocks to the front.