Burntorange70

Well-Known Member

Patch looks good. Keep up the nice work.

Patch looks good. Keep up the nice work.

Did you mill the intake face of the heads as well, or the intake? One will need to be milled to get the intake to bolt down.

Nice score on the 8.75"! Just a thought, but if you found a B-Body one you wouldn't have to run wheel spacers, or you could run thinner ones. Not sure how the bolt pattern would work for you though, not clear on what you have or are doing (I know you are running the SRT-4 wheels, just not how).

Lookin' good there young gun! It's guys like you to keep the mopars going:cheers:

Not clear on what you see that you don't like.

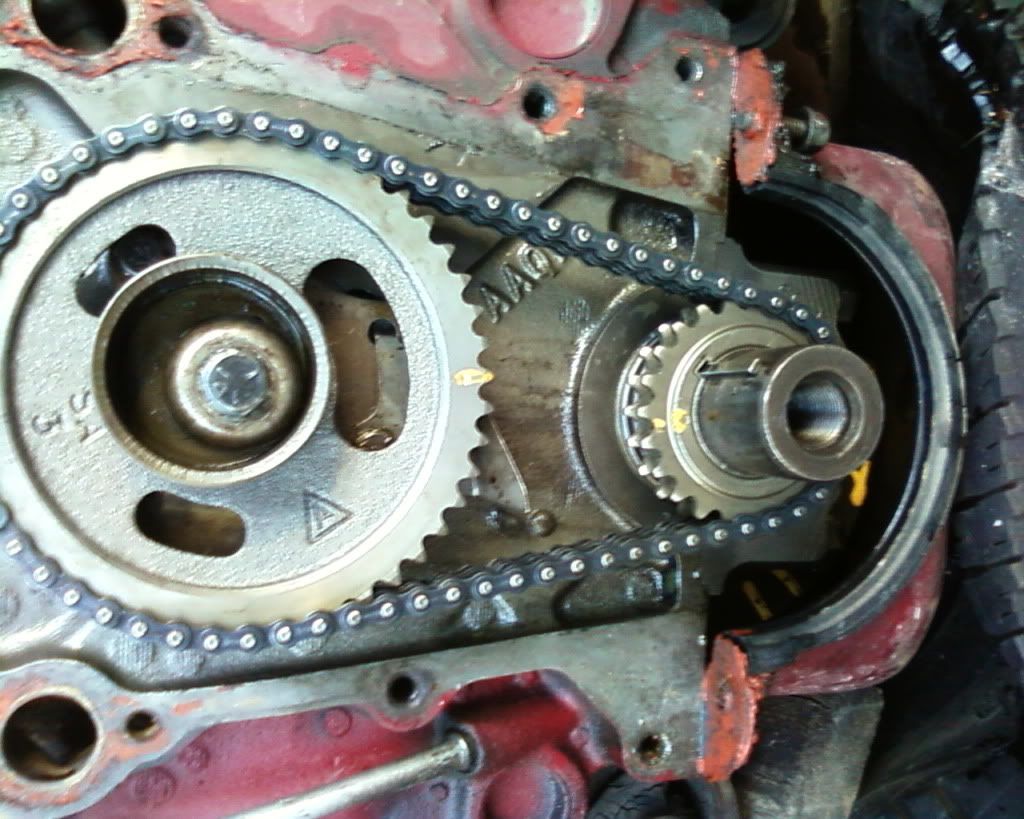

Not surprised the pistons are at 0 deck, with the notches they are definitely not stock. Should make a good motor, provided you don't have some work to do.