I'm not saying a SoftLok didn't work for you, no doubt it was an effective alternative to breaking parts despite the $2000 price tag. What i am saying is that there are now alternatives that are more effective, cost less, and have less maintenance.

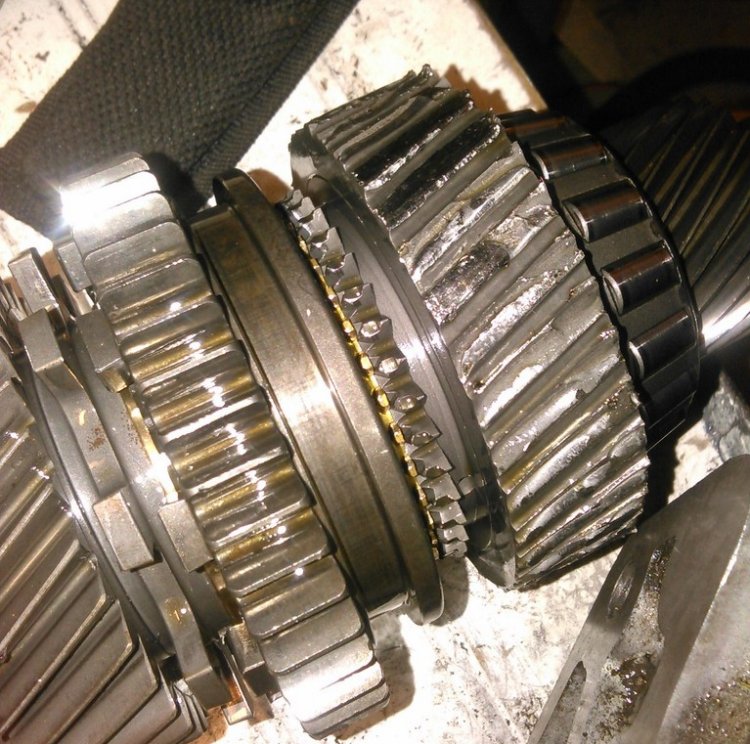

To illustrate what i'm talking about with regards to clutch slippage, here's some easy to interpret feedback on our ClutchTamer from an east coast NMRA Factory Stock racer. Powered by a 302ci crate engine, stick cars like his are required to run a diaphragm clutch. This guy was having a rough time, as he was a slick racer switching to radials. With a typical 4300 launch, the radials bogged the engine to 2300rpm and 1.7x 60's. Stepping up to a 4800rpm launch in an attempt to eliminate the bog, this is what happened to his faceplated TKO...

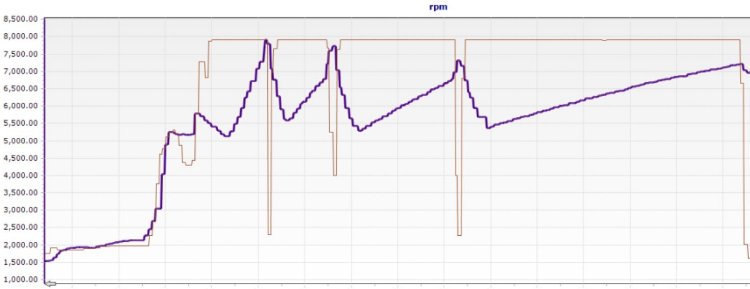

He repaired the transmission, and I sent him an in-dash version of the ClutchTamer to try. He installed the ClutchTamer, made a few test hits in the driveway to get familiar with it, then went to the track. His immediate results were dead hooked radials and back to back 1.45 60's. This graph is from a 1.42 run...

Couple months later, hes still putting down 1.4 60's at class weight with no transmission failures from 5200rpm launches. This increase in durability is due to two things-

1- a reduction of engine rpm loss before clutch lockup

2- spreading rpm loss over a longer time period

Both are beneficial on launch as well as after the shifts, as they team up to reduce shock to the drive train and tires.

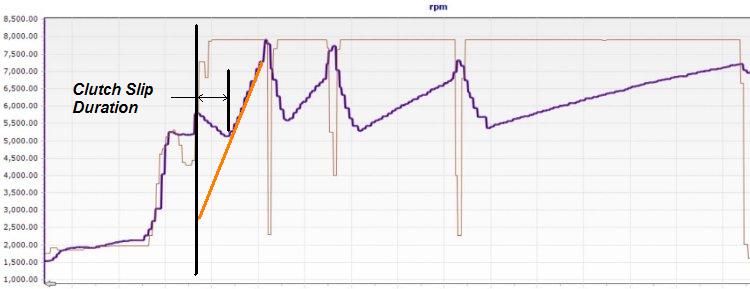

Here's the same graph w/ a couple lines added to help illustrate those benefits. His graph is fairly easy to understand, as there is very little wheelspin to confuse things...

The added orange line is a rough representation of the engine's ability to gain rpm in 1st gear.

The 1st added vertical black line represents the launch, or beginning of clutch engagement.

The 2nd added vertical black line represents the point of clutch lockup.

The distance between the two vertical black lines represents the time it took for clutch lockup to occur.

Clutch slip duration was roughly .7 seconds, engine rpm at lockup was about 5100.

If clutch lockup had occurred at .4 seconds, engine rpm would have been pulled down to appx 4200 on the orange line.

If clutch lockup had occurred at .25 seconds, engine rpm would have been pulled down to appx 3500 on the orange line.

This is a bit of a simplified explanation. Reduced engine output at lower rpms would also reduce the engine's ability to gain rpm, that added power loss is not reflected here. The basic point is- the earlier clutch lockup occurs, the lower the rpm point on the orange line that the engine will have to accelerate from.

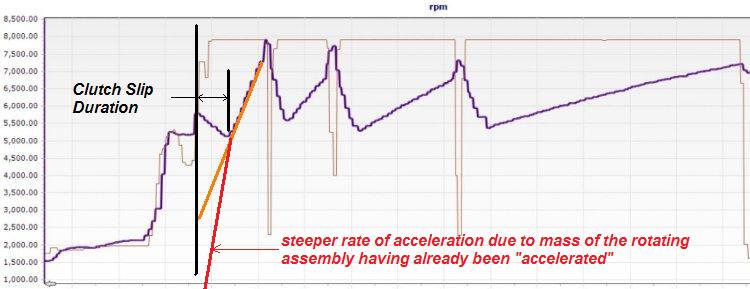

Anyone wonder why that orange line on the graph aligns with 2700rpm at launch instead of zero rpm? It's because a line representing rate of acceleration is actually even steeper before the clutch locks up. This happened because no power was used to accelerate the rotating assembly prior to clutch lockup, so more power was available to accelerate the car. Here's the same graph, with a red line added to represent acceleration rate before clutch lockup...

See how much steeper the car's acceleration rate was before clutch lockup?

This launch could have reached it's shift point even quicker if the clutch had slipped longer, as the car would have rode the trajectory of that steep red line to a higher point before switching to angle of the orange line. Same logic applies to clutch slip after the shifts, a car can simply accelerate quicker before the clutch locks up. Generally the longer you delay clutch lockup, the longer you ride a steeper acceleration rate.

My personal car has the deck stacked against it as far as parts choices, kept this way on purpose for proof of concept while developing my ClutchTamer project...

700whp

Toploader 4spd (faceplated) w/ small 1-1/16" input, 28 spl output, 2.78 1st

Steel 17# flywheel

Ram 2900lb diaphragm PP, 900 series disc currently

1310 u-joints, steel 2-1/2" x .065" driveshaft

10 bolt Chev rear 3.73 w/ TruTrac diff

275/60-15 MT radials

Driven everywhere it goes (gets 20mpg and burns 87 oct pump gas)

5.70's in the 1/8th w/ 1.30 60's, spraying right off the line without any delay at all

This is what happens in the 1st 6" off the line without delayed clutch lockup (simply disconnected the delay cylinder from the clutch pedal for a back to back test)...

That shaft was replaced with an identical 2-1/2" x .065" steel shaft, still in place 3 years later.

You don't need to buy anything from me to benefit from the concept, the refinements that evolved into the ClutchTamer mostly only make it more user friendly. My car still has the same modified $15 hydraulic screen door cylinder controlling the clutch pedal from when i started the project 5-6 years ago, it was the original "Hillbilly Clutch Slipper".