Where do ppl get these weird *** ideas from? Kim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

400/450 stroker....Cheap parts, lotta work.

- Thread starter IQ52

- Start date

-

The internet and car gatherings are full of funny people who claim some of the most unusual and dangerous things worked out great form them so “It must be true!”Where do ppl get these weird *** ideas from? Kim

Right? LMAO! A lot!!!!

I didn't get pictures of the actual damper installation, Cody and I were just having too much fun working together and I forgot to take any pictures.

So from this morning here are pictures of what we used to hone the 440 Source damper to my idea of the correct size. Used the mic to measure the crankshaft snout diameter, set the dial bore gauge to zero with the mic and measured the inside bore size of the damper. There was going to be .002" press fit.

Then we used the wheel cylinder hone for a single cylinder disc brake caliper to hone the damper bore to .001" press fit. You need a hone that has stones wide enough that they don't fall into the keyway slot in the damper while you are honing. For us it was the single cylinder brake caliper hone.

Welcome to our genuine Mopar damper installation kit. I've had two "installation kits" that broke the first time outta the box. This installation kit has never failed me. This time I slathered the long bolt and two washers the the ARP lube and tightened the bolt a bit. Then pulled the bolt back out and added the third washer and went until the short bolt would work with one washer.

We used a dab of oil on the crank snout and a dab on both the inside of the damper bore and the outer surface that runs in the timing cover seal. With crank snout temperature at approximately 70F and the damper at 50F or so, the damper then went up smoothly at less than 50 ft-lbs on the torque wrench and never clicked. I never tried a lower setting on the torque wrench 'cause everything was going so nice I didn't care what the torque really was. Both the Factory Service Manual (FSM) and the 440 Source instructions recommend the final torque on the damper bolt be 135 ft-lbs.

So from this morning here are pictures of what we used to hone the 440 Source damper to my idea of the correct size. Used the mic to measure the crankshaft snout diameter, set the dial bore gauge to zero with the mic and measured the inside bore size of the damper. There was going to be .002" press fit.

Then we used the wheel cylinder hone for a single cylinder disc brake caliper to hone the damper bore to .001" press fit. You need a hone that has stones wide enough that they don't fall into the keyway slot in the damper while you are honing. For us it was the single cylinder brake caliper hone.

Welcome to our genuine Mopar damper installation kit. I've had two "installation kits" that broke the first time outta the box. This installation kit has never failed me. This time I slathered the long bolt and two washers the the ARP lube and tightened the bolt a bit. Then pulled the bolt back out and added the third washer and went until the short bolt would work with one washer.

We used a dab of oil on the crank snout and a dab on both the inside of the damper bore and the outer surface that runs in the timing cover seal. With crank snout temperature at approximately 70F and the damper at 50F or so, the damper then went up smoothly at less than 50 ft-lbs on the torque wrench and never clicked. I never tried a lower setting on the torque wrench 'cause everything was going so nice I didn't care what the torque really was. Both the Factory Service Manual (FSM) and the 440 Source instructions recommend the final torque on the damper bolt be 135 ft-lbs.

Last edited:

Sweet. U will be done in no time. Kim

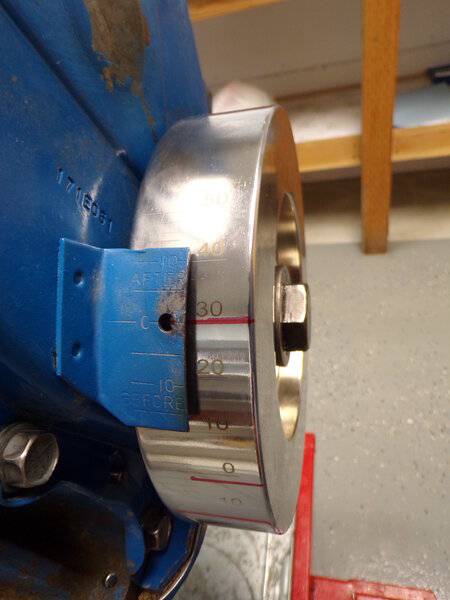

After installing the damper we needed to check the damper timing degree marks with the chain cover timing indicator. With the heads installed there would need to be a piston stop that was used in the #1 cylinder spark plug hole.

Enter a piston stop that Dad made for factory iron heads with an old spark plug, a piece of 3/8-16 all thread and a 3/8 jam nut. This same tool has been used by this family for at least 50 years.

With the crankshaft about 90 degrees before TDC on #1 cylinder, we install the piston stop in the #1 spark plug hole. Then slowly and GENTLY turn the crankshaft clockwise until it hits the pistons top. Mark a line on the damper corresponding to zero (0) on the cover timing tab.

Then go counter-clockwise with crankshaft until the piston hits the stop in that direction and mark the damper again at where zero (0) is on the cover tab. This time it just happens to be at 30 degrees on the damper. Now turn the crankshaft a little clockwise and remove the piston stop. It is no longer needed and this will prevent you from smashing into the piston stop during the rest of the process.

Now we need to rotate the engine until we can measure and make a third mark in the center of the two marks we made. This will be TDC on #1 cylinder when the center red line on the damper is placed at zero on the timing cover. Let's do that....

Huh! The timing cover zero doesn't match the damper zero.

No Rob (RRR), after the aluminum intake manifold bolt down theory, we are not going to remark the entire damper to get the zeros to align.

I think we'll just put a line of paint on the timing cover tab corresponding to the damper zero. Because if we use the original timing cover zero and the damper zero, we're always going to be, what, in reality 2 degrees advanced from where we think we are? Sometimes I get really damned confused at this point.

Enter a piston stop that Dad made for factory iron heads with an old spark plug, a piece of 3/8-16 all thread and a 3/8 jam nut. This same tool has been used by this family for at least 50 years.

With the crankshaft about 90 degrees before TDC on #1 cylinder, we install the piston stop in the #1 spark plug hole. Then slowly and GENTLY turn the crankshaft clockwise until it hits the pistons top. Mark a line on the damper corresponding to zero (0) on the cover timing tab.

Then go counter-clockwise with crankshaft until the piston hits the stop in that direction and mark the damper again at where zero (0) is on the cover tab. This time it just happens to be at 30 degrees on the damper. Now turn the crankshaft a little clockwise and remove the piston stop. It is no longer needed and this will prevent you from smashing into the piston stop during the rest of the process.

Now we need to rotate the engine until we can measure and make a third mark in the center of the two marks we made. This will be TDC on #1 cylinder when the center red line on the damper is placed at zero on the timing cover. Let's do that....

Huh! The timing cover zero doesn't match the damper zero.

No Rob (RRR), after the aluminum intake manifold bolt down theory, we are not going to remark the entire damper to get the zeros to align.

I think we'll just put a line of paint on the timing cover tab corresponding to the damper zero. Because if we use the original timing cover zero and the damper zero, we're always going to be, what, in reality 2 degrees advanced from where we think we are? Sometimes I get really damned confused at this point.

Last edited:

I had to do this exact same thing with the 340 I built. But mine was 2 * the other way. Kim

80fbody

Well-Known Member

Could simply drill out the two spot welds and adjust the pointer on the cover.

Unless something moved when I installed the damper (and I don't think it did) I had a similar result. And yes I have since cleaned and painted the block.

Chrysler engineering always was a little ahead

Chrysler engineering always was a little ahead

After installing the damper we needed to check the damper timing degree marks with the chain cover timing indicator. With the heads installed there would need to be a piston stop that was used in the #1 cylinder spark plug hole.

Enter a piston stop that Dad made for factory iron heads with an old spark plug, a piece of 3/8-16 all thread and a 3/8 jam nut. This same tool has been used by this family for at least 50 years.

With the crankshaft about 90 degrees before TDC on #1 cylinder, we install the piston stop in the #1 spark plug hole. Then slowly and GENTLY turn the crankshaft clockwise until it hits the pistons top. Mark a line on the damper corresponding to zero (0) on the cover timing tab.

View attachment 1715724241 View attachment 1715724242

Then go counter-clockwise with crankshaft until the piston hits the stop in that direction and mark the damper again at where zero (0) is on the cover tab. This time it just happens to be at 30 degrees on the damper. Now turn the crankshaft a little clockwise and remove the piston stop. It is no longer needed and this will prevent you from smashing into the piston stop during the rest of the process.

View attachment 1715724243

Now we need to rotate the engine until we can measure and make a third mark in the center of the two marks we made. This will be TDC on #1 cylinder when the center red line on the damper is placed at zero on the timing cover. Let's do that....

View attachment 1715724244

Huh! The timing cover zero doesn't match the damper zero.

No Rob (RRR), after the aluminum intake manifold bolt down theory, we are not going to remark the entire damper to get the zeros to align.

I think we'll just put a line of paint on the timing cover tab corresponding to the damper zero. Because if we use the original timing cover zero and the damper zero, we're always going to be, what, in reality 2 degrees advanced from where we think we are? Sometimes I get really damned confused at this point.

View attachment 1715724245

<snort> You know me all too well, sir. lol

beanhead

Well-Known Member

Really huh.Where do ppl get these weird *** ideas from? Kim

A machinist I ain't, but a lot of stuff those guys at H-youzz put on their "tech" page makes me scratch my head...IQs response set that straight.

Just a quick thing that I had to rediscover when doing a prelube.....To oil the 1,3,5,7 rockers (left bank) you need to be on #8 TDC (fire). To oil the right bank rockers (2,4,6,8) you need to be on #6 TDC (fire). Now I must clean the oil off the shop floor and then crawl around in the irrigation ditch to measure for the new mainline offset. Oh Joy!

mopowers

Well-Known Member

Just a quick thing that I had to rediscover when doing a prelube.....To oil the 1,3,5,7 rockers (left bank) you need to be on #8 TDC (fire). To oil the right bank rockers (2,4,6,8) you need to be on #6 TDC (fire). Now I must clean the oil off the shop floor and then crawl around in the irrigation ditch to measure for the new mainline offset. Oh Joy!

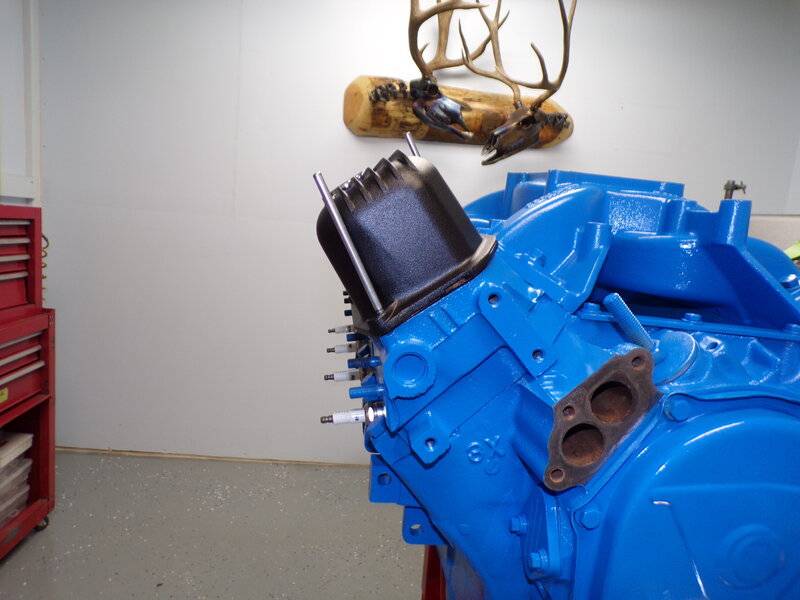

View attachment 1715726567

I love the detail of this build! Quick question - what paint did you use on it? It looks killer?

Just a quick thing that I had to rediscover when doing a prelube.....To oil the 1,3,5,7 rockers (left bank) you need to be on #8 TDC (fire). To oil the right bank rockers (2,4,6,8) you need to be on #6 TDC (fire). Now I must clean the oil off the shop floor and then crawl around in the irrigation ditch to measure for the new mainline offset. Oh Joy!

View attachment 1715726567

The paint is Dupli-Color DE 1601 FORD BLUE. Off the shelf at my local NAPA. Heh heh. I paint all my personal engines with the lighter colored Ford Blue.I love the detail of this build! Quick question - what paint did you use on it? It looks killer?

Funny that I never had any customer ever want my Ford Blue. It was always some kinda orange something-or-other they required.

Last edited:

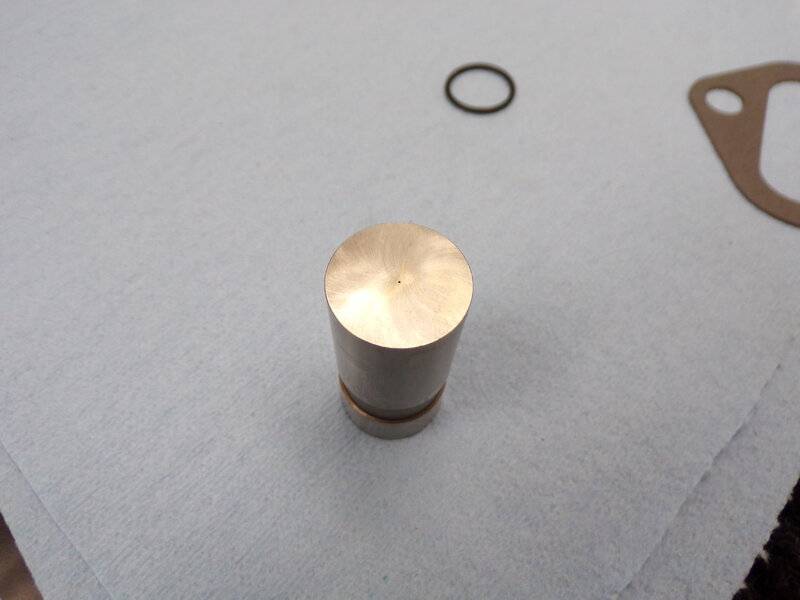

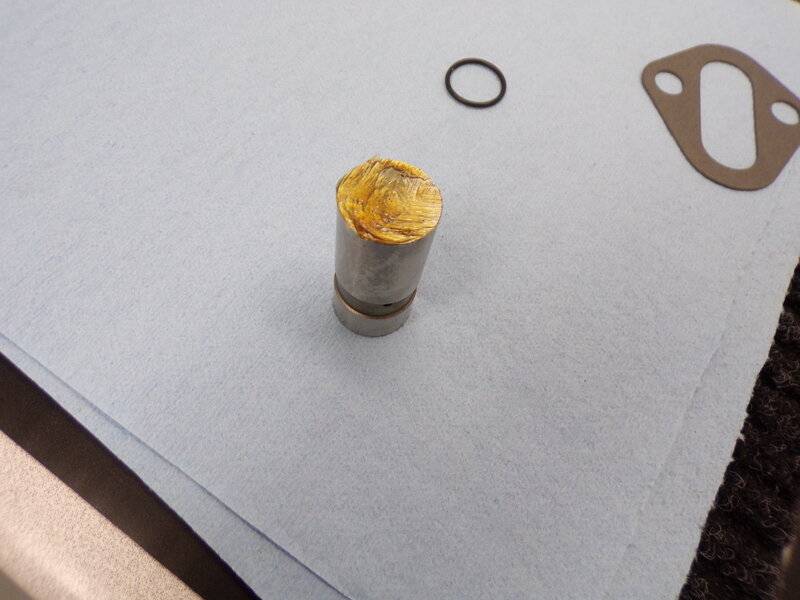

We're using the Comp Cams EDM solid lifters......

Spray clean them with solvent and blow air through this oil supply hole in the lifter body and make sure I can feel air against my finger tip blowing out of the EDM hole............

The lifter sides get break-in oil and the face gets Driven engine assembly grease....

Spray clean them with solvent and blow air through this oil supply hole in the lifter body and make sure I can feel air against my finger tip blowing out of the EDM hole............

The lifter sides get break-in oil and the face gets Driven engine assembly grease....

Love these Mopar Performance cast aluminum valve covers. They are tall enough to fit all my aftermarket rockers and the rocker shaft correction kit at the same time.................

They do however present a problem bolting them up to a factory iron head.....................

Must have been a 'better idea' from an ex-Ford engineer to think the valve cover bolts should come off the head at these angles.

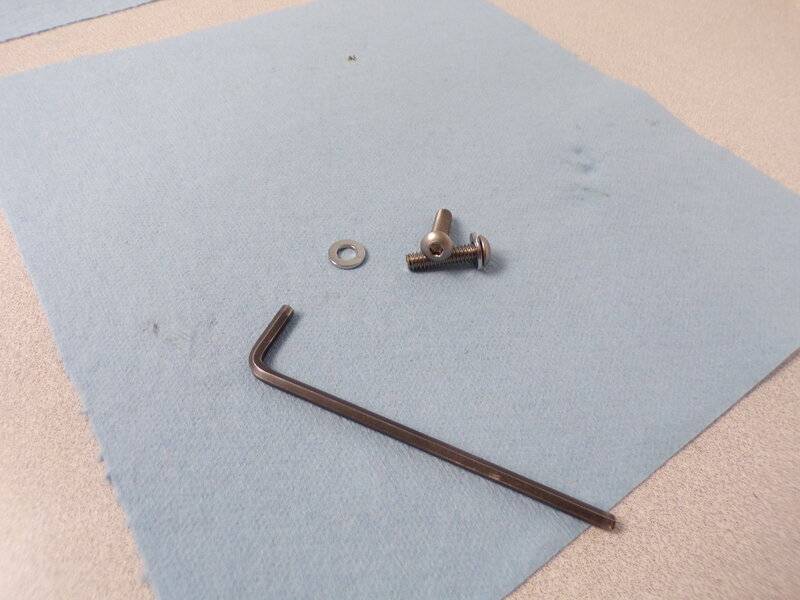

Studs with factory 6-point nuts or factory bolts are almost impossible to tighten in the bottom holes. I just use these stainless steel button-head allen screws...........

An allen wrench (even better if it has a ball end) works like a charm and the stainless steel looks clean............

Oh goody...it looks like I get to go now and fabricate the irrigation line offset we measured up in the ditch yesterday.......hot damn!

They do however present a problem bolting them up to a factory iron head.....................

Must have been a 'better idea' from an ex-Ford engineer to think the valve cover bolts should come off the head at these angles.

Studs with factory 6-point nuts or factory bolts are almost impossible to tighten in the bottom holes. I just use these stainless steel button-head allen screws...........

An allen wrench (even better if it has a ball end) works like a charm and the stainless steel looks clean............

Oh goody...it looks like I get to go now and fabricate the irrigation line offset we measured up in the ditch yesterday.......hot damn!

GTMaracucho

Well-Known Member

Nice Job

Your hand is lookin chubby. You been pickin up on the twinkies again, haven't you?

LOL!Your hand is lookin chubby. You been pickin up on the twinkies again, haven't you?

Roberto!

Chubby hand?

Really?

Chubby hand!

You couldn't point out how clean my hand was while working with the lifters?

Well the agape is still intact but the phileo may have taken a small hit with the 'chubby hand' crack.

The camera tilts the valve tips and chubbies up my hand. My story and I'm stickin' to it.

Now NOBODY gets to hear about the low compression 440 rock crawler engine for Cody's Plymouth Trail Duster because of you...

Signed, poor old sensitive Jim

What! No tails of Cody’s Trail Duster?!?!?!?!?!?!?

Quick! Where’s the wood pile and matches for to tie up Rusty to?!?!?!

Quick! Where’s the wood pile and matches for to tie up Rusty to?!?!?!

What! No tails of Cody’s Trail Duster?!?!?!?!?!?!?

Quick! Where’s the wood pile and matches for to tie up Rusty to?!?!?!

Easy now. It was only a "chubby hand" comment......and......and........and.......was I wrong? LOL

LMAO!

Hi, I gotta question for you since you're doing this and probably done what I'm going to do. I have a 440 crank cut to b mains, I have a very nice 400 block, I'm going to mock up the b-rods & pistons to get a visual on just how far the deck clearances will be. The question is, I'm sure of bearings needing champers but have you just cut them with a carbide or something to just make some mock up bearings ?Our steel flywheel returns from the loan out tomorrow so maybe we can get this dog on the dyno soon.

Or is it best to buy some ?

Your advice please & thank you !

-