I will look around and see if I can find you one!Looking good, Don!

I would also like one of those dimming mirrors. It would be cool to have one on my '66 when our 2010 Audi doesn't have one!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

65 Dart Wagon Conversion to a Sedan Delivery

- Thread starter 65 Dartman

- Start date

-

Oh, that isn't at all necessary! I'm sure I can find one over here. Thanks!I will look around and see if I can find you one!

After fabrication of my little consolette for the Door Ajar/Fasten Seat Belt lights and Heated Seat switches, it just didn't "look" right.

So I fabricated a pair of ends. I did these in 2 pieces for each side - the flat front pieces and a double compound curve from front to back and side to side. After grinding and smoothing the welds with my little rolox, I think it the overall look is much better.

So I fabricated a pair of ends. I did these in 2 pieces for each side - the flat front pieces and a double compound curve from front to back and side to side. After grinding and smoothing the welds with my little rolox, I think it the overall look is much better.

Last edited:

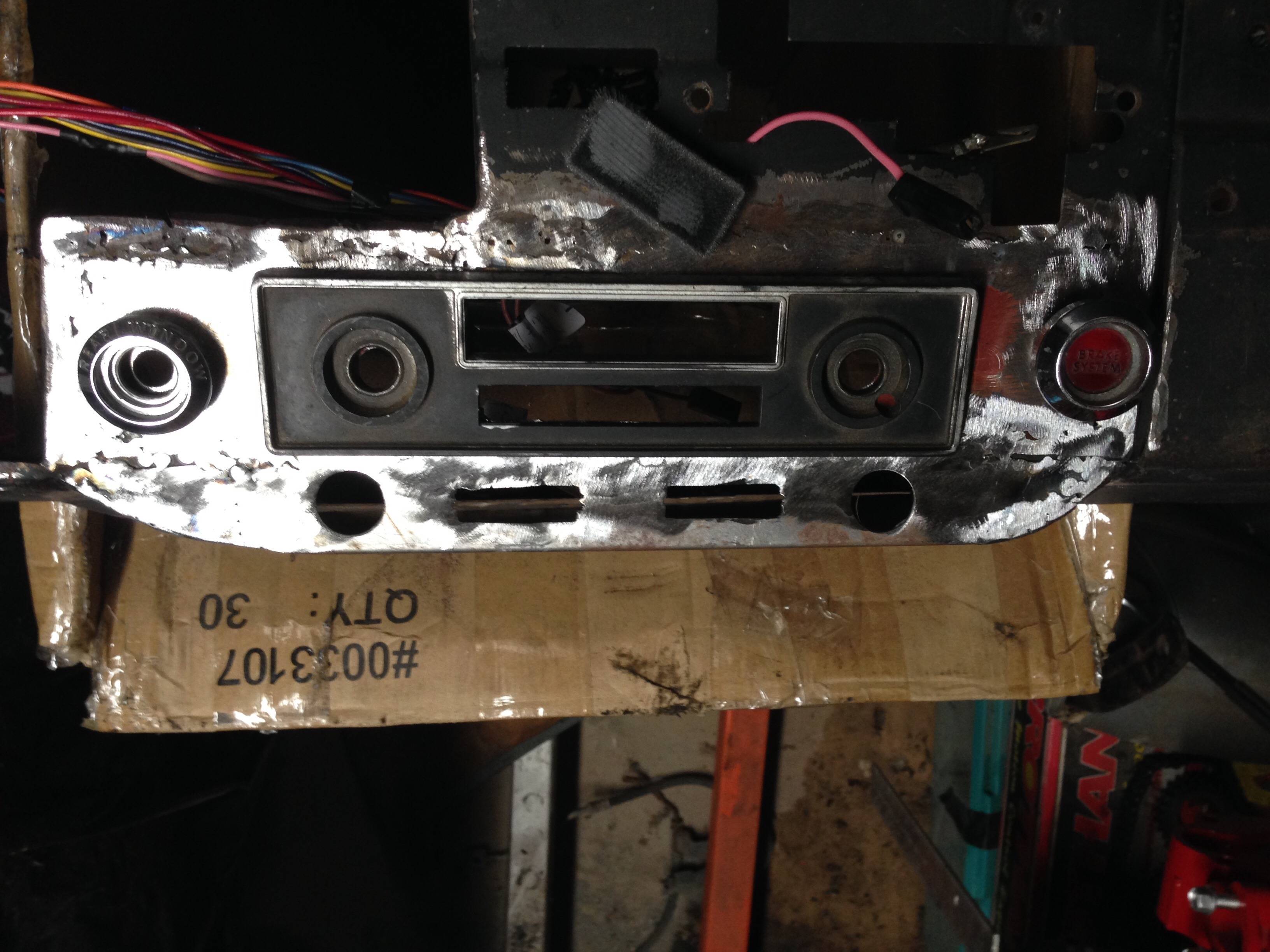

i have a Brake System warning light from a 67 Coronet and would like to use it to indicate a failure in the brake hydraulic system. My Dakota Digital dash has an icon for brakes which I will use for the emergency brake. I decided to move the cigarette lighter from the instrument cluster ignition switch to the right of the radio and install the Brake System light in the ignition switch hole. Looks good there!

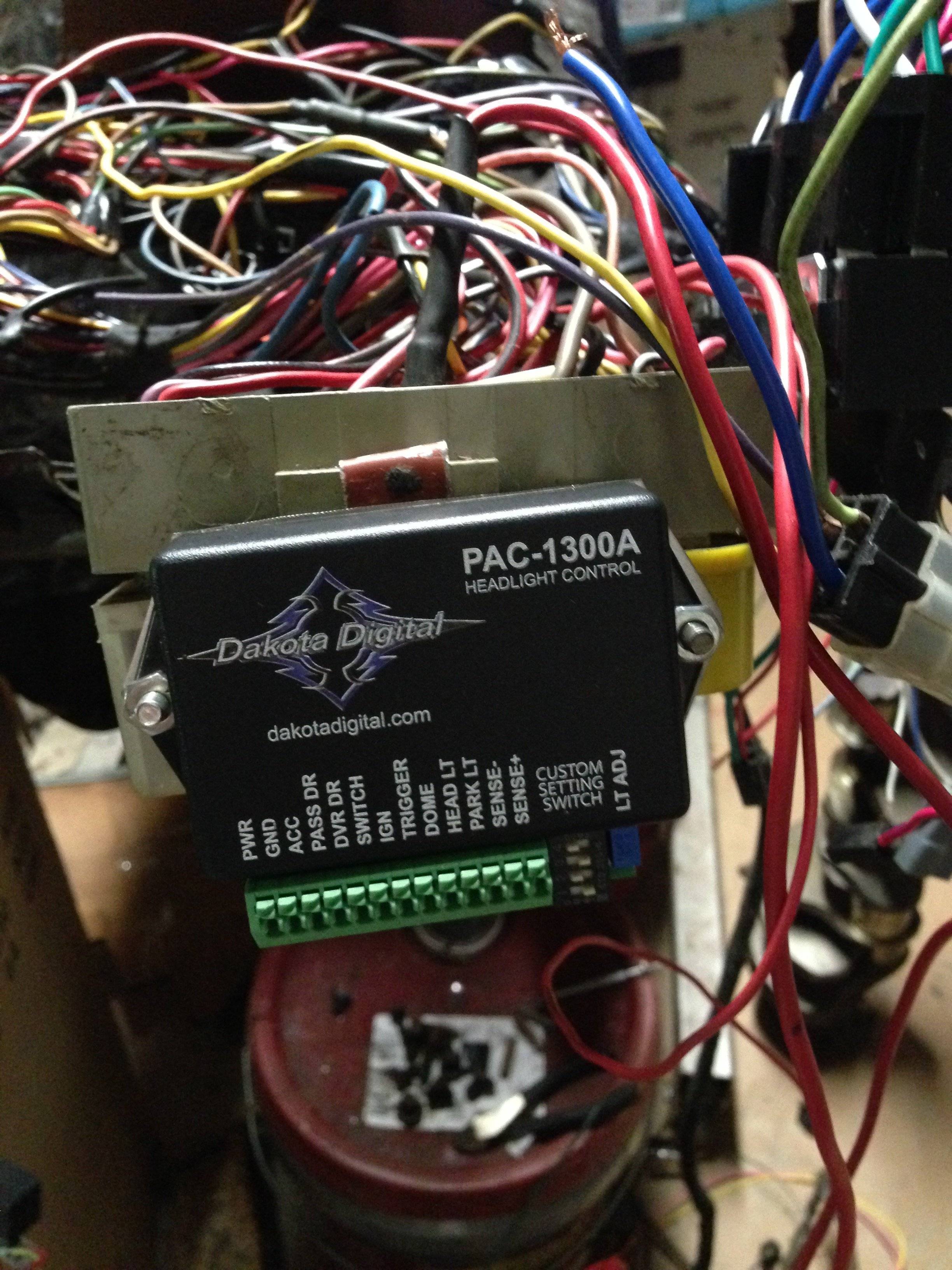

I'be got the cigarette lighter hole drilled to the right of the radio bezel and the hole on top of the dash for the Dakota Digital headlight sensor so it was time to fit the underdash harness to make sure everything is going to the right component. I found out the stock fuse panel bracket wasn't going to work with the Mirada fuse panel so I fabricated a bracket that would work with it. I needed to mount the relays included with the Dakota Digital PAC 1300 headlight and accessories module. The relays fit perfectly on the side of the fuse panel and the PAC1300 module fits great on the back side of the fuse panel.

Had to unwrap the harness to reroute the wiring for the Brake System and Oil light as well as reroute wiring going to the relays, PAC1300, wiring that will be connected to the dash module and to the rear body harness.

Had to unwrap the harness to reroute the wiring for the Brake System and Oil light as well as reroute wiring going to the relays, PAC1300, wiring that will be connected to the dash module and to the rear body harness.

All finished and harness rewrapped.

All finished and harness rewrapped.

Last edited:

Good work of art Don!I'be got the cigarette lighter hole drilled to the right of the radio bezel and the hole on top of the dash for the Dakota Digital headlight sensor so it was time to fit the underdash harness to make sure everything is going to the right component. I found out the stock fuse panel bracket wasn't going to work with the Mirada fuse panel so I fabricated a bracket that would work with it. I needed to mount the relays included with the Dakota Digital PAC 1300 headlight and accessories module. The relays fit perfectly on the side of the fuse panel and the PAC1300 module fits great on the back side of the fuse panel.View attachment 1714969122 Had to unwrap the harness to reroute the wiring for the Brake System and Oil light as well as reroute wiring going to the relays, PAC1300, wiring that will be connected to the dash module and to the rear body harness. View attachment 1714969120 All finished and harness rewrapped.View attachment 1714969123

View attachment 1714969116

Looks great, Don!

I left the dash harness in place in the dash in order to confirm there's enough slack to install the firewall junction block, to reach the body wiring harness plug, the door switches, etc and to locate the best place to mount the Dakota Digital instrument cluster control box and both auxiliary fuse panels.

The best place I found to install them was on the kick panel where they will be easily accessible to install wiring and check the fuses. One fuse panel is for stuff that requires a constant hot, such as the Dakota Digital control box, the PAC1300 and its associated relays, rear power window and driver's seat lumbar support. The other fuse box will have power only when the key is on or in ACC. It also powers part of the control box, part of the PAC1300, and heated seats - yes, the original 66 Barracuda seats will have heated seats and driver's lumbar support!

The best place I found to install them was on the kick panel where they will be easily accessible to install wiring and check the fuses. One fuse panel is for stuff that requires a constant hot, such as the Dakota Digital control box, the PAC1300 and its associated relays, rear power window and driver's seat lumbar support. The other fuse box will have power only when the key is on or in ACC. It also powers part of the control box, part of the PAC1300, and heated seats - yes, the original 66 Barracuda seats will have heated seats and driver's lumbar support!

Worldclass Don! What's next? Heated rear window. It's facinating to follow all your experiments on your wagon.

Worldclass Don! What's next? Heated rear window. It's facinating to follow all your experiments on your wagon.

IDK about a heated rear window since it goes up and down - might be a problem with the wires.

Nothing you can't work out.IDK about a heated rear window since it goes up and down - might be a problem with the wires.

I will be using a 6 speaker radio system - 2 6 x9's in the rear side panels and a pair of small 3 inch speakers at the ends of the dash with factory Mopar speaker grills. I saved the grills and speakers from some Mopar I parted out years ago. I'll probably upgrade them as they are just tweeters and speaker technology has really improved since I saved them.

I was trying to decide what would fit in the center where the original speaker was located. Using the original speaker frame as a guide,

I was trying to decide what would fit in the center where the original speaker was located. Using the original speaker frame as a guide,

I found a pair of 4 inchers could be used. Another member makes a bracket for later A Bodies to mount a couple of speakers in the original speaker area. So, using his idea I came up with a plate that I tack welded to the speaker frame, cut out for the speakers and got both 4 inch coaxials mounted. Best part it all fits in the original location.

I found a pair of 4 inchers could be used. Another member makes a bracket for later A Bodies to mount a couple of speakers in the original speaker area. So, using his idea I came up with a plate that I tack welded to the speaker frame, cut out for the speakers and got both 4 inch coaxials mounted. Best part it all fits in the original location.

Now I have to decide on a radio - a modern radio with a touchscreen, CD, Bluetooth, etc or the later A Body AM/FM I had converted to modern internals with multi speaker capability but no CD or any of the other modern conveniences. Decisions decisions!

Now I have to decide on a radio - a modern radio with a touchscreen, CD, Bluetooth, etc or the later A Body AM/FM I had converted to modern internals with multi speaker capability but no CD or any of the other modern conveniences. Decisions decisions!

PapstXX

Well-Known Member

Great work Don !

i am follow you Don

i am follow you Don

Mopar Tim had described in one of his threads how he converted from the hood torsion bars to gas struts off a Mitsubishi. I thought that was a great idea as it gets rid of those ugly torsion bars. Got my son and grandson to give me a hand the other day setting the hood in place. I got it all bolted and aligned yesterday and today found a complete Mitsu gas strut kit including all the hardware on eBay today and got it ordered. After I get it installed and make sure the hood opens and closes properly, I'll get my helpers to help remove the hood so work can continue on the engine compartment.

Will turn out great Don.Mopar Tim had described in one of his threads how he converted from the hood torsion bars to gas struts off a Mitsubishi. I thought that was a great idea as it gets rid of those ugly torsion bars. Got my son and grandson to give me a hand the other day setting the hood in place. I got it all bolted and aligned yesterday and today found a complete Mitsu gas strut kit including all the hardware on eBay today and got it ordered. After I get it installed and make sure the hood opens and closes properly, I'll get my helpers to help remove the hood so work can continue on the engine compartment.

I got my Mitsu strut kit yesterday. I had previously removed the hood torsion bars so that was already done.

I am using the forward hole in the hinge arm so I needed a nut to secure the ball studs. The stud takes a metric nut (can't remember the size as I bought a locking nut that fit the threads).

I am using the forward hole in the hinge arm so I needed a nut to secure the ball studs. The stud takes a metric nut (can't remember the size as I bought a locking nut that fit the threads).

I raised and supported the hood as high as I thought practical- I suspect it's higher than would be with the hood torsion bars.

To install the lower Strut mount, the fenders need to be removed (which mine are). I positioned the struts on the side of the cowl behind the where the splash panel is mounted and secured them with self-tapping screws.

I see the screws protrude more than I would prefer on the kick panel side. I will get some bolts just long enough to get a thin jam nut to tighten down. Can't be having these screws be making holes in my brand new kick panels!

And now the hood opens pretty much on it's own and no more ugly torsion bars!

I raised and supported the hood as high as I thought practical- I suspect it's higher than would be with the hood torsion bars.

To install the lower Strut mount, the fenders need to be removed (which mine are). I positioned the struts on the side of the cowl behind the where the splash panel is mounted and secured them with self-tapping screws.

I see the screws protrude more than I would prefer on the kick panel side. I will get some bolts just long enough to get a thin jam nut to tighten down. Can't be having these screws be making holes in my brand new kick panels!

And now the hood opens pretty much on it's own and no more ugly torsion bars!

Last edited:

Looks great Don!I got my Mitsu strut kit yesterday. I had previously removed the hood torsion bars so that was already done.View attachment 1714983773 I am using the forward hole in the hinge arm so I needed a nut to secure the ball studs. The stud takes a metric nut (can't rememember the size as I bought a locking nut that fit the threads).

View attachment 1714983781

I raised and supported the hood as high as I thought practical- I suspect it's higher than would be with the hood torsion bars. View attachment 1714983782

To install the lower Strut mount, the fenders need to be removed (which mine are). I positioned the struts on the side of the cowl behind the where the splash panel is mounted and secured them with self-tapping screws.

View attachment 1714983785 View attachment 1714983786

I see the screws protrude more than I would prefer on the kick panel side. I will get some bolts just long enough to get a thin jam nut to tighten down. Can't be having these screws be making holes in my brand new kick panels!View attachment 1714983800

And now the hood opens pretty much on it's own and no more ugly torsion bars! Now I will have to see if the tailgate can be done as well! After seeing the results, I will be doing the same modification on the 65 Barracuda hood and truck lid.View attachment 1714983788

Rockerdude

Rock n' Roll and A-bodies

Love the hood strut idea! Keep up the good work.

Looks pretty straight forward. How did you decide the mounting points?

Looks pretty straight forward. How did you decide the mounting points?

Mopar Tim said he used the hole closest to the front of the hinge for the ball stud, which slid right in place. The strut comes already extended so after attaching the strut to the ball stud and the hood opened to whatever height is desired and the strut hanging by the ball stud, the lower mounting point is pretty well fixed to a small arc at the bottom. I used a flat surface on both sides to install the lower mount and it worked out quite well.

Last edited:

Using a spare slant, I wanted to start mocking up the intakes I have with my Clifford long Tube headers and see what will fit with a Sanden AC compressor since I am adding factory AC to the wagon. The mount is from a 79 F Body. As I figured, it appears it will be impossible to run triple Webers with any kind of AC compressor - Sanden or RV2.

The Offy 4 barrel - no problem.

Much to my surprise the Dutra Hyperpak clears with room to spare.

With either 4 barrel intake I'll have to fabricate new rear braces Since the headers will definitely be in the way. Someone might ask why am I adding AC to a modified slant - because I want to be comfortable in the summer months and because I can!

The Offy 4 barrel - no problem.

Much to my surprise the Dutra Hyperpak clears with room to spare.

With either 4 barrel intake I'll have to fabricate new rear braces Since the headers will definitely be in the way. Someone might ask why am I adding AC to a modified slant - because I want to be comfortable in the summer months and because I can!

Mega cool, what you are doing here.

Only you can do it! You got some great skills. Can you put the compressor just in front of the steering box?Using a spare slant, I wanted to start mocking up the intakes I have with my Clifford long Tube headers and see what will fit with a Sanden AC compressor since I am adding factory AC to the wagon. The mount is from a 79 F Body. As I figured, it appears it will be impossible to run triple Webers with any kind of AC compressor - Sanden or RV2.

View attachment 1714987162

The Offy 4 barrel - no problem.

View attachment 1714987163

Much to my surprise the Dutra Hyperpak clears with room to spare.

View attachment 1714987164

With either 4 barrel intake I'll have to fabricate new rear braces Since the headers will definitely be in the way. Someone might ask why am I adding AC to a modified slant - because I want to be comfortable in the summer months and because I can!

Darthomas

Ashamed to be seen in foreign cars

I have changed so many gas struts over the years on printing presses that I find my Dart's torsion bar hood supports to be elegant and beautiful.

I like stuff that just keeps working.

Never had trouble with them.

I like stuff that just keeps working.

Never had trouble with them.

Mega cool, what you are doing here.

Thanks!

Only you can do it! You got some great skills. Can you put the compressor just in front of the steering box?

If I eliminate the power steering box I could use an A100 van alternator mounting bracket (I have one somewhere!) and possibly mount the AC compressor there. That particular bracket installs in place of the PS pump and I am not giving up my Stage III PS box Steer and Gear built for me!

I have changed so many gas struts over the years on printing presses that I find my Dart's torsion bar hood supports to be elegant and beautiful.

I like stuff that just keeps working.

Never had trouble with them.

I really liked what Mopar Tim did on his Dart hood struts, so I followed suit. And IMO, cleans up the engine compartment quite a bit.

-