Nice work. Doing it out in the open like that is the way to go. I may abandon my plans for same as the cross member is installed and the new AMD floor pan is in. I am worried about butchering the cross member. At least if it were out in the open, I could buy another if need be. Keep up the good work.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

67/68/69 cuda dilemma

- Thread starter moparmat2000

- Start date

-

moparmat2000

Well-Known Member

My plan was to leave it semi boxed in instead of just flat strapping it in like most of these are done. Doing most of this from inside the car with no floor pan installed is for sure the cats meow.

I feel leaving it semi boxed helps keep more of the strength than just cutting it all completely out and flat strapping it. The OD unit is pretty straight and isnt wider at the front where the crossmember mod is. This is one of the reasons I am leaving it semi boxed, plus it's easier to fabricate the strap that way. The drawing shown, the blue is the original crossmember, red is the added piece, the orange is the floor pan angle.

The bolt in crossmember will be made of 11 gage sheet steel, and be bolted with 4 bolts to the torsion bar crossmember. This should all be plenty strong.

I feel leaving it semi boxed helps keep more of the strength than just cutting it all completely out and flat strapping it. The OD unit is pretty straight and isnt wider at the front where the crossmember mod is. This is one of the reasons I am leaving it semi boxed, plus it's easier to fabricate the strap that way. The drawing shown, the blue is the original crossmember, red is the added piece, the orange is the floor pan angle.

The bolt in crossmember will be made of 11 gage sheet steel, and be bolted with 4 bolts to the torsion bar crossmember. This should all be plenty strong.

Last edited:

Leaving it partially boxed is a great idea.......That is what I was planning. Cutting the loop right out didn't sit right with me.

moparmat2000

Well-Known Member

Leaving it partially boxed is a great idea.......That is what I was planning. Cutting the loop right out didn't sit right with me.

It leaves room if you want to add an extra strap on top of the one that's there. This car will get upgraded subframe connectors from what's currently in there as well. Even if your floor is in, you can still carefully cut out the section of the floorpan where it overlaps the crossmember, modify the crossmember from inside the car, then weld the floor section back in. Carpet covers it up anyways.

moparmat2000

Well-Known Member

Made 2 more weld passes at the front to beef it up more, and ground the rest down. Welded in 2 of the mount tube reinforcements, will weld up the other 2 when I build the mount. A little primer, and onto the next job. Getting that trans under there, and temp bolted in.

Last edited:

Sweet....Looks like it could have bees done at the factory. You should reproduce a kit with the cross member and trans support. Bet they'd move quick.

moparmat2000

Well-Known Member

Would be a great idea, but it was a lot of fiddling around to get it just right before burning it in. I suppose they are all a little bit different. I left a roadmap for anybody wanting to duplicate though.Sweet....Looks like it could have bees done at the factory. You should reproduce a kit with the cross member and trans support. Bet they'd move quick.

moparmat2000

Well-Known Member

Done for the night, but wanted to slide that trans under there. Fortunately for me it lines up with my chain hoist and theres no floor in the car. Easy to lift it into place for mock up. That OD unit is effing big!!!

Nice...That is a lot of room.

moparmat2000

Well-Known Member

Well I did a little caliper measuring and also feeler gage and straight edge measured the TDC of the old pistons before removal and they were .080" in the hole at TDC. The new ones are KB167s at current deck height if my math is correct they will be .009" in the hole at TDC. The block will be surfaced probably .004" -.005" to clean up the gasket surfaces. The CR calculator I used puts this .030 overbore 318 with the 302s and felpro permatorque gaskets at 9.33-1 CR . Unless I decide on thinner steel shim headgaskets. Should be just fine. I need to do a CC check on the heads to get an exact number, but it should be close.

Last edited:

moparmat2000

Well-Known Member

Got the trans up and in. Tailshaft blocked up. Chassis has been leveled, and engine block and transmission set to 5° down. Industry standard is 3° to 5° on engine and trans angle. I figure after I build the mount to a 5° driveline angle, I can always shim it up to 3° pretty easy if i needed to. Looks like theres a few appendages on the trans that others have lopped off on their installs to make it fit the floor pan. I will be doing the same as well when the time comes. Mid 70s GM truck mount is installed. Got to get the bolt in crossmember fabbed up and installed. Chain hoist made it super easy with no floor in there lol.

Last edited:

mygasser

Well-Known Member

looking good

did you set the driveline angle off the carb pad? that should be pretty much level (for fuel in the carb bowls levelishness), the motor/trans will then be at an angle as they design in the level carb pad to allow for driveline angle.

if you set it off the crank' centreline ignore me

neil.

did you set the driveline angle off the carb pad? that should be pretty much level (for fuel in the carb bowls levelishness), the motor/trans will then be at an angle as they design in the level carb pad to allow for driveline angle.

if you set it off the crank' centreline ignore me

neil.

moparmat2000

Well-Known Member

Hi Neil,

With chassis level front to back and side to side, and carb pad level. The angle finder on the front of the engine block on timing cover mating surface is at 3° pointing down at the trans. I wanted to bring it further down to 5° because should I need to shim the trans it's easier to go up with shims, than have it set at 3°, welded in, and have to go down. Heres where we were at before I lowered the back end to 5° . Carb level. driveline angle tipped down 3°.

With chassis level front to back and side to side, and carb pad level. The angle finder on the front of the engine block on timing cover mating surface is at 3° pointing down at the trans. I wanted to bring it further down to 5° because should I need to shim the trans it's easier to go up with shims, than have it set at 3°, welded in, and have to go down. Heres where we were at before I lowered the back end to 5° . Carb level. driveline angle tipped down 3°.

mygasser

Well-Known Member

i knew you'd have it sussed mate. i refer to my last statement then...... ignore me

moparmat2000

Well-Known Member

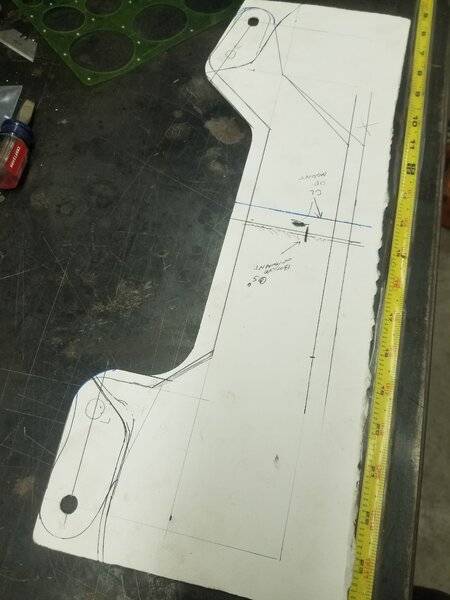

Working on that trans mount crossmembers. Built a template out of cardstock, transferred it to 14 gage steel sheet which is the same as the stock one. I think it turned out great. I have a bit more to go on it, but so far I am happy with the results. It's similar to the US cartool one, but not an exact copy. Theirs uses thicker steel, however once its boxed and welded its plenty strong. Part looks welded crooked, but that's the camera angle, its straight.

Working on that trans mount crossmembers. Built a template out of cardstock, transferred it to 14 gage steel sheet which is the same as the stock one. I think it turned out great. I have a bit more to go on it, but so far I am happy with the results. It's similar to the US cartool one, but not an exact copy. Theirs uses thicker steel, however once its boxed and welded its plenty strong. Part looks welded crooked, but that's the camera angle, its straight.

View attachment 1715711170

View attachment 1715711171

View attachment 1715711172

View attachment 1715711173

View attachment 1715711174

View attachment 1715711175

You are definitely an artist brother.

Nice work Matt!

JDMopar

Well-Known Member

Looks awesome! The welds on the white one are absolutely perfect!!!!

moparmat2000

Well-Known Member

I used unidirectional bonding strips on that one.Looks awesome! The welds on the white one are absolutely perfect!!!!

moparmat2000

Well-Known Member

I think I'm just about done with this one. Will sandblast and primer our "new" trans mount. Still have to drill the remaining holes in the crossmember and weld in the tubular reinforcements. The plate that the rubber mount bolts to is 10 gage plate.

Last edited:

moparmat2000

Well-Known Member

Gonna keep this cardboard template. I think the install looks pretty good.

Matt......You should have made a couple while you were at it. I'll bet you'd get lots of interest.

moparmat2000

Well-Known Member

This thing was a ***** to make. I'm sure there would be interest in this. But one and done. I have waaay more to do on this car lol.

True enough!

moparmat2000

Well-Known Member

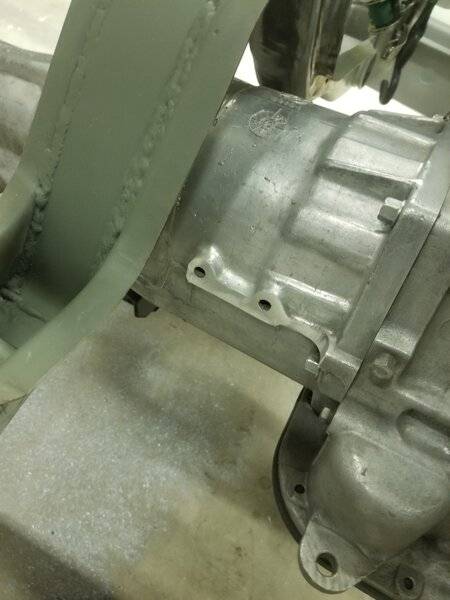

Some of the unused "appendages" on the 42RH overdrive unit and tailshaft need to be removed so it will fit the stock tunnel. Of course I am OCD about how **** looks even if I can't see it so I did a bit of cutting and carving.

On the LH of the OD it will hit the stock floor shifter mechanism which I will adapt to the 42RH. The piece on the RH of the OD, it will never clear the stock tunnel. On the tailshaft, I am concerned the tabs will rub and vibrate against the trans tunnel. Heres the results.

On the LH of the OD it will hit the stock floor shifter mechanism which I will adapt to the 42RH. The piece on the RH of the OD, it will never clear the stock tunnel. On the tailshaft, I am concerned the tabs will rub and vibrate against the trans tunnel. Heres the results.

Last edited:

-