I think I totally underestimated the time needed to rebuild the front end. I came out of the gates strong thanks to Mark and Tom for letting me use their lift to drop out the whole front assembly. Heck even the tear down went quickly and without a hitch. But since then it's been a slow deal.

It's the cleaning and the stripping that is a time suck. I'll admit that I expected this part to take some time considering I don't have a good media cabinet and a limited set of tools oh and limited funds lol.

All that being said progress is still progress.

First off the PST super front end Kit is really nice. Heck I even got both Poly and rubber LCA bushings so my options were open. After reading through several threads I decided to stay with the rubber LCA bushing but in retrospect I would have saved a lot of time re-using the outer and inner sleeves going with polys.

Welcome to my LCA nightmare lol.

I cleaned the outer shell and prepped it to weld in a grade 8 washer.

Unfortunately I didn't not take many pictures of the first try thinking that I would on the second arm so I don't have shots of the welded washer or the how the outer shell failed and tore apart while trying to press it out.

What a mess... The shell tore apart while trying to press it out, so I decided I would not try welding again because there wasn't much material left to make a good contact. Assessing what I had left I figured using a hacksaw blade to cut down the side and rolling the shell onto itself with a chisel was the next step. Funny thing was that the shell seemed fused to the LCA wall and it took a lot of effort even with the shell split. I worked at i and took my time and eventually got them out.

After removing the shells I took some time with a brake hone and steel wool to clean up the walls (I was very careful with my hammer and chisel I don't think others were as kind).

I've decided replacing Lower control arm bushings are one of the things I like the least. My opinion would be different if I had the proper equipment.

I'm sure others didn't have as difficult a time as I did so don't take my experience to be yours. Hopeful it is not.

Most parts cleaned up well, I even did a good job with the K but no matter how clean I get it I seem to find more grease.

I used a combination technique to clean components...

1, First I sprayed with degreaser and pressure washed.

2. Then I soaked on alki-clean solution. Back to the pressure washer.

3. After I hit it with various discs, wire wheels, sandpaper and steel wool.

Wish I had a hot tank and a sandblaster because they would have saved me lots of time and done a better job. Lol

You might be asking why not powder coat??

Got a quote of $150 for just the k frame which seemed high to me. I vacillated between powder-coat and POR because these pieces take a lot of road abuse and I've heard mixed results from folks who had them powder coated. I can still change my mind but will have to decide this week.

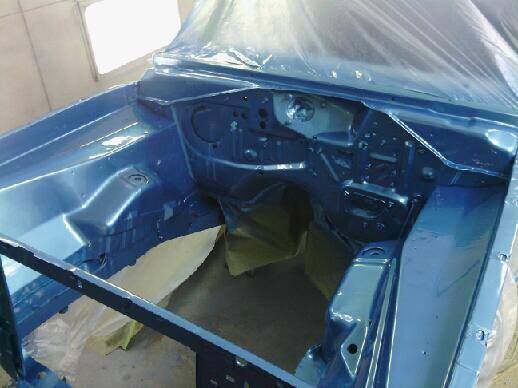

Next steps are to treat the metal then paint and reassemble so I can mount the engine and trans to it. Then ultimately put it all back in the car which should be ready to receive the suspension and drive line very soon.

No pressure lol