Finally getting around to dealing with this ole girl's inability to hold her liquid.

Ordered up a new tank grommet (Dale's Cuda shop) and have the floor pan gasket coming from DMT. I've been dying to see the actual state of the fuel filler tube-to-fuel tank union.

First order of business - get the flip cap off and remove the screws holding the upper part of the fill tube to the quarter panel. As stated earlier, this was easy as the anti-tamper screws had already been replaced with regular phillips heads.

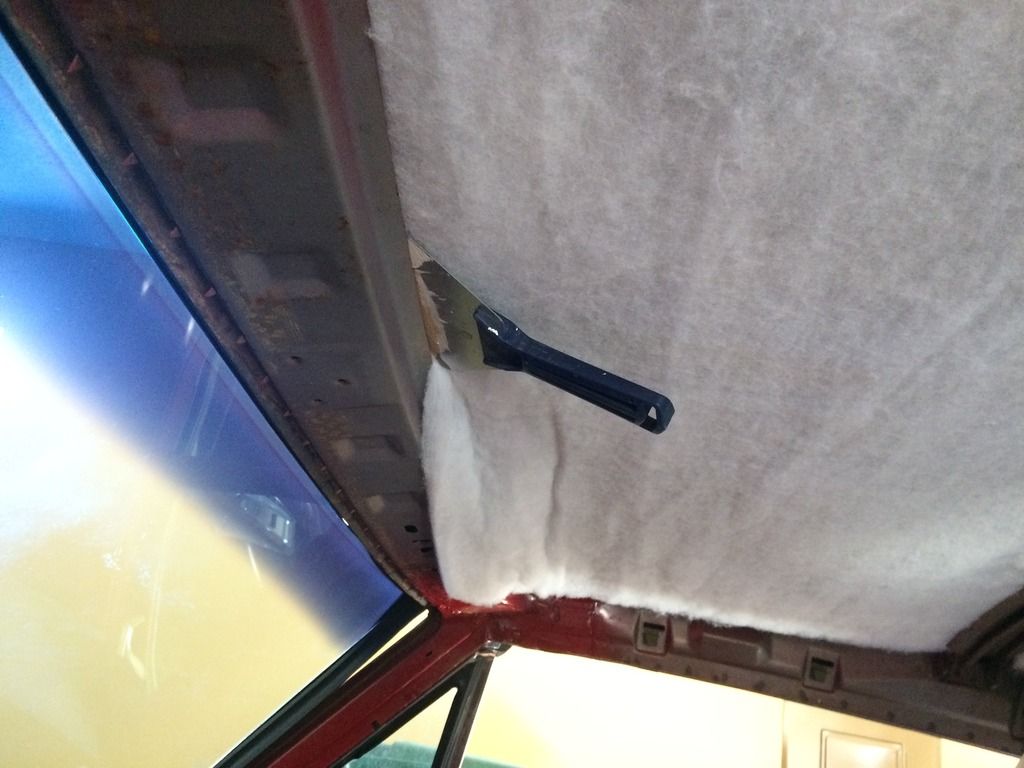

Next, clear out the cargo area and remove the stamped steel cargo floor. This permits access to the floor gasket (5 screws). My floor seal was doing a poor job of keeping the outside outside.

Now its time to increase the working room between the fill port and the fuel tank. This means undoing the fuel tank straps and lowering the tank.

Floor jack in place for fuel tank management....

With the tank down about 5 inches or so, wiggling the fill tube out was fairly painless.

Here's a shot of the old floor seal, tank grommet, and the gunky fill tube...

And at the other end of the tube, the body seal...

Ordered up a new tank grommet (Dale's Cuda shop) and have the floor pan gasket coming from DMT. I've been dying to see the actual state of the fuel filler tube-to-fuel tank union.

First order of business - get the flip cap off and remove the screws holding the upper part of the fill tube to the quarter panel. As stated earlier, this was easy as the anti-tamper screws had already been replaced with regular phillips heads.

Next, clear out the cargo area and remove the stamped steel cargo floor. This permits access to the floor gasket (5 screws). My floor seal was doing a poor job of keeping the outside outside.

Now its time to increase the working room between the fill port and the fuel tank. This means undoing the fuel tank straps and lowering the tank.

Floor jack in place for fuel tank management....

With the tank down about 5 inches or so, wiggling the fill tube out was fairly painless.

Here's a shot of the old floor seal, tank grommet, and the gunky fill tube...

And at the other end of the tube, the body seal...