What is the relay box out of I'm looking to do something similarThis is what I had to do to close my hood.View attachment 1715573286

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Classic Auto Air in 67 Barracuda Factory Non AC

- Thread starter loganscuda

- Start date

-

CudaFish1968

Well-Known Member

In 2012 I did a 5.9L magnum swap. I had the whole 1996 dodge ram. I used the PDC (fuse, relay box) from that truck. When I did the 5.7L hemi swap I went to pull a part and got a PDC from a late 90s to early 00 ram truck. It's not hard to take apart and rework to use.

Now I did modify it alot to suite my electrical needs.

Now I did modify it alot to suite my electrical needs.

CudaFish1968

Well-Known Member

If you make a electrical drawing of the relay box and how you want to power the relays either sinking or sourcing, it will make it easy peasy to power up everything. I made a electrical drawing of all the circuits I had to modify to make it work and will help out when I have to troubleshoot problems.

Thanks for the info that's the route I'm going to take just couldn't tell from the pic what box you usedIf you make a electrical drawing of the relay box and how you want to power the relays either sinking or sourcing, it will make it easy peasy to power up everything. I made a electrical drawing of all the circuits I had to modify to make it work and will help out when I have to troubleshoot problems.

ESP47

Well-Known Member

I'm beginning the installation in my 70 non-factory air Dart. I bought the perfect fit with the blue tooth diagnostics. It came with Installation Manual 1967-72 Chrysler "A" Bodies, Document #1-3062 Copyright 2021 ClassicAutoAir / 07.21

The booklet looks to have been designed by somebody in high school. It's not totally awful but it's also not great. One example is an illustration on page 23. It shows the installation of the heater box from the engine bay view. It's showing you to use two supplied bolts to bolt the box to the firewall. The problem is that it looks like you will have to drill two new holes with no instruction on where. After careful examination of the heater box and the firewall, you realize that you are to use two of the existing holes from the old fan motor.

View attachment 1715861657

Another lack of explanation is Bench Calibrating the system before installing it in the vehicle. Pages 9-10 are titled "Operation" and show all the positions of the controls and what should be happening with the unit. Then you get to the middle right of page 10 and it reads "Your controls are now fully calibrated to your unit...." Wait, what? We were calibrating? How? And on one of the bags in the box it says you must follow the steps in the BENCH CALIBRATION packet before installation. There is no packet for that. I was poking around their website and under "Support" I found a video on how to bench calibrate. The installation manual looks like it was not written by a technical copy writer and more like something that was deemed to be too long so they edited it down and then never went back to proofread it to see if it made sense.

View attachment 1715861658

View attachment 1715861659

View attachment 1715861656

I also found that my temperature slider only has half the range of travel. I looked at the supplied Temp Control Integrator, which is a sliding potentiometer, and it only has half of its range of travel as well but the opposite direction. If I shorten the wire 3/4" and make a new loop, both the temp control slider and the Integrator will have full travel.

View attachment 1715861665

I'd be interested in hearing any other experiences on installation of the newer system. I expect to have to do a few modifications but leaving out important information is not so good. I mean how difficult to print, "IT IS MANDITORY THAT YOU CALIBRATE YOUR SYSTEM BEFORE INSTALLING IT IN YOUR VEHCILE. VISIT THE SUPPORT PAGE ON OUR WEBSITE TO VIEW A SIMPLE HOW-TO VIDEO"

And the bolts through the firewall, it would just take a few dashed lines directing the bolts through the two holes on the drawing to illustrate that. Simple.

View attachment 1715861660

I'm in the process of installing this kit right now in my 68 Barracuda and I also had the issue where the temp control slider only had half the range of travel and wound up having to create a new loop in the wire.

Does the temperature slider work the water valve as well as a blend door inside the box or does it just control the water valve? Reason I ask is that I noticed that it only takes about 25% travel with the temp control slider in order to have the valve be fully open or fully closed. It's as if the potentiometer has too wide a range of resistance. Either that or the rest of the range of the slider controls a blend door inside the box but I never heard anything moving inside the box when I continued to move the slider the rest of the range.

loganscuda

This/These

It is just for the valve only. After I got mine running I had my wife open and close it so I could se the travel of the valve. So I could adjust the switch where I wanted it.I'm in the process of installing this kit right now in my 68 Barracuda and I also had the issue where the temp control slider only had half the range of travel and wound up having to create a new loop in the wire.

Does the temperature slider work the water valve as well as a blend door inside the box or does it just control the water valve? Reason I ask is that I noticed that it only takes about 25% travel with the temp control slider in order to have the valve be fully open or fully closed. It's as if the potentiometer has too wide a range of resistance. Either that or the rest of the range of the slider controls a blend door inside the box but I never heard anything moving inside the box when I continued to move the slider the rest of the range.

ESP47

Well-Known Member

It is just for the valve only. After I got mine running I had my wife open and close it so I could se the travel of the valve. So I could adjust the switch where I wanted it.

Was yours the same deal where you only have to slide the control an inch and a half or so to go from closed to open?

loganscuda

This/These

Yes it is very little and it doesn’t seem like it does anything when you slice de it, there isn’t a no force or friction.

Just installed this kit in my 1970 Dart. The position problem with the temp slide seems to be universal and Classic doesn't seem bothered by it, or interested in fixing it. My temp slide seems to work correctly now that I modified the wire to provide full travel. On my car when I tried to put their adapter on the dash defrost vent above the controls and then tried to install their hose it all interfered with the function slide - I got rid of their adapter, installed a section of original hose and ran their smaller hose up into it. It all works fine at this point. The other big issue that I ran into is that the bracket on the box that is toward the inside of the car was impossible to mount because there was no way to get to the top hole to drill into the cowl without removing the whole dash frame from the car. I turned their bracket around did some bending, and added a bracket to the cowl so that the holes could be drilled through the glove box hole.

I didn't like their glove box so I took a later model plastic glove box and modified it to fit and then mounted their control box (where all the wires go) inside the glove box as well as the relay.

There were also belt clearancing issues with the compressor at the thermostat housing and the water pump neck fin (just one). The brackets came from Bouchilon (printed right on them) and Bouchilon knew about these needs and got me going. The big aggravation to me is that the compressor has 2 belt grooves and the crank pulley has 2 grooves for them but they don't line up so you can only use one belt and Classic and Bouchilon both think this is just fine ((grrrr)). I will eventually do a bunch of work to move the crank pulley out so both belts can be used, but then you have to space the water pump pulley (shallower pulley) and the power steering forward so that they line up with the crank. This by the way is on a 1970 motor with the aluminum water pump so your 68 would be completely different.

All in all I have had this installed and fully operating for 2 months and maybe 500 miles and it works great, but a Perfect Fit??? Hell NO!!!

I didn't like their glove box so I took a later model plastic glove box and modified it to fit and then mounted their control box (where all the wires go) inside the glove box as well as the relay.

There were also belt clearancing issues with the compressor at the thermostat housing and the water pump neck fin (just one). The brackets came from Bouchilon (printed right on them) and Bouchilon knew about these needs and got me going. The big aggravation to me is that the compressor has 2 belt grooves and the crank pulley has 2 grooves for them but they don't line up so you can only use one belt and Classic and Bouchilon both think this is just fine ((grrrr)). I will eventually do a bunch of work to move the crank pulley out so both belts can be used, but then you have to space the water pump pulley (shallower pulley) and the power steering forward so that they line up with the crank. This by the way is on a 1970 motor with the aluminum water pump so your 68 would be completely different.

All in all I have had this installed and fully operating for 2 months and maybe 500 miles and it works great, but a Perfect Fit??? Hell NO!!!

ESP47

Well-Known Member

Just installed this kit in my 1970 Dart. The position problem with the temp slide seems to be universal and Classic doesn't seem bothered by it, or interested in fixing it. My temp slide seems to work correctly now that I modified the wire to provide full travel. On my car when I tried to put their adapter on the dash defrost vent above the controls and then tried to install their hose it all interfered with the function slide - I got rid of their adapter, installed a section of original hose and ran their smaller hose up into it. It all works fine at this point. The other big issue that I ran into is that the bracket on the box that is toward the inside of the car was impossible to mount because there was no way to get to the top hole to drill into the cowl without removing the whole dash frame from the car. I turned their bracket around did some bending, and added a bracket to the cowl so that the holes could be drilled through the glove box hole.

I didn't like their glove box so I took a later model plastic glove box and modified it to fit and then mounted their control box (where all the wires go) inside the glove box as well as the relay.

There were also belt clearancing issues with the compressor at the thermostat housing and the water pump neck fin (just one). The brackets came from Bouchilon (printed right on them) and Bouchilon knew about these needs and got me going. The big aggravation to me is that the compressor has 2 belt grooves and the crank pulley has 2 grooves for them but they don't line up so you can only use one belt and Classic and Bouchilon both think this is just fine ((grrrr)). I will eventually do a bunch of work to move the crank pulley out so both belts can be used, but then you have to space the water pump pulley (shallower pulley) and the power steering forward so that they line up with the crank. This by the way is on a 1970 motor with the aluminum water pump so your 68 would be completely different.

All in all I have had this installed and fully operating for 2 months and maybe 500 miles and it works great, but a Perfect Fit??? Hell NO!!!

Thanks for the info. Did you test the temp slider while watching the water valve? If so is it doing the same deal where it only needs to slide halfway to go from fully open to fully closed (or vice versa) and the rest of the travel does absolutely nothing?

I think what they did was create the potentiometer slider by using the perch for the upper slider, which is further from the attachment to the heater control mechanism than the bottom slider perch is. So it works perfectly for the top slider and doesn't leave you enough room for the bottom slider. Modifying the wire gives you full slider travel but the issue seems to be that the potentiometer was designed for half slider travel so the second half of travel in the temp slider doesn't do anything to the water valve.

I was able to get the bracket to work on my 68 Cuda. Wound up having to use a 90* drill with a drill bit to get a hole started and then I ran the self tapper they supplied in after that. The new bracket is nice because it's way more stout than the old looking strap they used to use. I was also able to attach the relay to it.

Got the firewall plate installed yesterday. What an ill fitting turd that thing is. That was definitely a two person job with one person having to twist and push the plate with all their might to get it to line up with the factory holes.

I'm fully expecting every single step to fight me as much as the previous steps have so the pulley alignment will be no surprise.

Where did you wind up installing your ecu? I put mine above the kick panel on the passenger side.

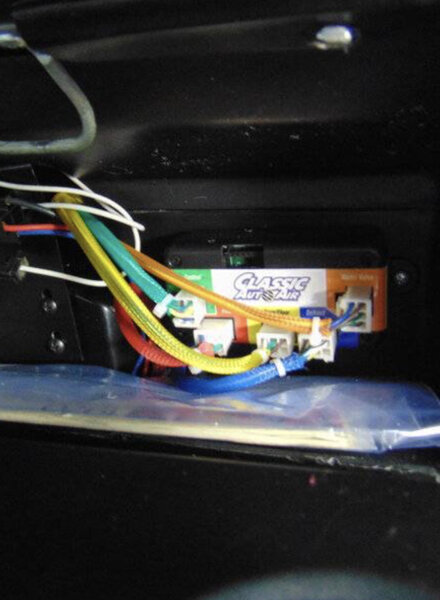

So the pics are of the inside of my glove box - a modified later model plastic factory dart glove box. I cut half the back out to fit. Under the relay you can see the Classic braket that I flipped around. The relay and control unit are screwed to the glove box for easy access and I still have more room in there than the cheapo thing that classic sent me.

I had the same deal with the heater valve control. I modified the wire and I never checked the effective travel - it was closed in one direction, and open in the other and half way in the middle and that made me happy. I sent pictures and explained the situation to the tech support folks and they didn't really seem to care or want to work with me to fix the situation for future buyers.

Have you tried to install the defroster hoses yet???

I started with an original AC firewall with the BIG hole for the blower, so I never got to see how the unit would have fit as intended as I had to make brackets to adapt their stuff to the AC firewall - fortunately somebody here had already done this and provided a template for the conversion.

I also didn't like the idea of just installing the water control valve to the hose and letting it flop around, so I fabbed a bracket to hold the valve

The bracket holds the valve and the return hose and the AC hoses run under the bracket to hold them on the top of the fenderwell and attaches to two existing holes in the face of the fender well.

Have you tried to install the defroster hoses yet???

I started with an original AC firewall with the BIG hole for the blower, so I never got to see how the unit would have fit as intended as I had to make brackets to adapt their stuff to the AC firewall - fortunately somebody here had already done this and provided a template for the conversion.

I also didn't like the idea of just installing the water control valve to the hose and letting it flop around, so I fabbed a bracket to hold the valve

The bracket holds the valve and the return hose and the AC hoses run under the bracket to hold them on the top of the fenderwell and attaches to two existing holes in the face of the fender well.

BY the way don't just accept the fittings for the AC hoses if they don't suit you. I had one of the fittings for the compressor point the hose up too far so I complained and they sent me a differently configured fitting... Here's the before and after:

loganscuda

This/These

What heck is this Mine didn’t have this contraption

loganscuda

This/These

This either. What the heck is going on here. I have a cable with an actual valve in the line

loganscuda

This/These

I ordered mine with uncrimped hoses so I cold run them a little different and crimped them myself

All that stuff came in my kit except for the bracket to mount the water valve. They switched to electric valves and controls a couple years ago. I had looked at their kit about 4 years ago when I was contemplating my project and they switched over since then. When did you get your set up? I think now all the kits have lengths of hose and loose fittings. They assume if you have to take the car to an AC place to get it charged, the same place can make up the hoses and then if they leak it is all on the AC shop.

Last edited:

They recommend that you build your controls from their kit and an original factory non-AC control assembly and then plug it all together, hook it to a car battery and test all the functions in the box before you put it in the car. That way if you have problems it is before all this is stuffed up under your dash... an excellent idea!

ESP47

Well-Known Member

I had the same deal with the heater valve control. I modified the wire and I never checked the effective travel - it was closed in one direction, and open in the other and half way in the middle and that made me happy. I sent pictures and explained the situation to the tech support folks and they didn't really seem to care or want to work with me to fix the situation for future buyers.

Have you tried to install the defroster hoses yet???

I started with an original AC firewall with the BIG hole for the blower, so I never got to see how the unit would have fit as intended as I had to make brackets to adapt their stuff to the AC firewall - fortunately somebody here had already done this and provided a template for the conversion.

I also didn't like the idea of just installing the water control valve to the hose and letting it flop around, so I fabbed a bracket to hold the valve

View attachment 1716096418

The bracket holds the valve and the return hose and the AC hoses run under the bracket to hold them on the top of the fenderwell and attaches to two existing holes in the face of the fender well.

View attachment 1716096419

Sounds like yours works better than mine since it was halfway open at the halfway point of the slider travel.

Had no idea about the bracket for the water valve. I'll probably wind up having to do the same thing. I haven't gotten to the point of hooking the ducting up yet. I got the box installed, the firewall plate on and started running the overflow line. They forgot to put the 90* adapter for the line in with the kit and I don't feel like waiting on them to send me one so I just picked one up at the hardware store. I'm going in order so I'll start on the water valve and heater hose install this weekend.

Great tip about the fittings because that second fitting you got from them routes the line much much better. I'll keep that in mind.

In my experience, if you know what you want from Classic and go through the tech support folks, they will send replacement pieces to make things work better. Please keep posting on your project. I'm taking off on a loooong road trip (over a month) so hearing what might fail before it does is a good thing!

scatpackbee

Well-Known Member

In my experience, if you know what you want from Classic and go through the tech support folks, they will send replacement pieces to make things work better. Please keep posting on your project. I'm taking off on a loooong road trip (over a month) so hearing what might fail before it does is a good thing!

I’m really interested in hearing if your evaporator freezes up after about an hour of continuous use like mine does.

The evaporator is in the box, right??? Does it just stop cooling until it thaws???

scatpackbee

Well-Known Member

Yes.

The output air temp starts to climb slowly.

The cooling air would fully return after about 30 minutes of system shutdown.

The output air temp starts to climb slowly.

The cooling air would fully return after about 30 minutes of system shutdown.

How long ago did you install yours???

scatpackbee

Well-Known Member

About 6 or 7 years ago.

-