It sounds like the engine is still on the dyno. Throw on a smaller carb and see if it runs better. That won't take long and I have never seen a dyno room that didn't have a few different known good carbs sitting around for instances just like this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disappointing dyno results

- Thread starter jawbone

- Start date

-

When you guys plotted off the curve, it looks like it was running out of fuel.

I was talking about airflow not fuel flow. You can put a thousand CFM carburetor on that motor and properly jet it and it will use as much air as it needs. It's up to you to jet the thing.Actually a 1000 CFM carb will have very large jets so I would think that even though the engine is only calling for 600 CFM it would still be running rich. While we know most of the details on his motor we still don’t know what part number carb that he is using.

I cannot see it making more power on a smaller carburetor. Those original AVS carburetors were "around" only 500 CFM. They didn't flow a lot. If it's running rich, it either has a carburetor problem, or doesn't have enough timing. Just one peon's opinion.

After carefully reviewing your posted cam specs I believe that your problem is not your cam.

What are you disappointed in? That cam is a torque cam so you should be looking at the level lower RPM toque not HP. What is the compression ratio of the engine? Headers? Duel Exhaust? Does it have a crossover if duel? How far back from the head is the crossover? When using a torque cam the exhaust is critical to get the max out of it.

Last edited:

If it doesn't meet your expectations, then lower your expectations...

junkyardhero

Well-Known Member

agree.After carefully reviewing your posted cam specs I believe that your problem is not your cam.

either the cam is somehow wrong: marked incorrectly, ground incorrectly or installed incorrectly or there is something amiss with the rest of the setup: compression ratio calculated wrong, flatted out some lobes on break in, distributor is off time, carb is only getting 3/4 of throw from whatever apparatus they've got hooked up.

Actually I believe I read somewhere 554 cfm. On a stock dual plane manifold, 4 cylinders would get 277 cfm. Definitely could take a bigger carb, but the path I would take is tune that carb and verify the timing is right and that includes making sure the distributor has the right advance curve in it.I cannot see it making more power on a smaller carburetor. Those original AVS carburetors were "around" only 500 CFM. They didn't flow a lot. If it's running rich, it either has a carburetor problem, or doesn't have enough timing. Just one peon's opinion.

Other than that I, I believe compression is suspect.

I agree. They made good power stock and this one cam wise and carburetor wise is close to stock. No reason it shouldn't make as much as a stock 340. Thing is, it might be. Put it on another dyno and it'll be different. lol The only real way is to put it on a drag strip.Actually I believe I read somewhere 554 cfm. On a stock dual plane manifold, 4 cylinders would get 277 cfm. Definitely could take a bigger carb, but the path I would take is tune that carb and verify the timing is right and that includes making sure the distributor has the right advance curve in it.

Other than that I, I believe compression is suspect.

Rmoore

Well-Known Member

Sounds like your engine guy , cam guy , carb guys are all on something ! You have spent your hard earned money with these guys , and was given a dis service by all !

junkyardhero

Well-Known Member

he said that the carb was done by woodruff, which is known for putting out good work. and that the dyno operator swapped a carb they had kicking around, so you can extrapolate from that what you want-- and for me, that absolves any kind of carb issue; save for the mechanical operation of the carb on the dyno itself maybe hanging up or not allowing full throttle.Sounds like your engine guy , cam guy , carb guys are all on something ! You have spent your hard earned money with these guys , and was given a dis service by all !

the cam is sus AF. they sent him the wrong one once, and then sent another. how'd he know it was wrong to begin with? who's to say the new one is right?

the engine builder is a wild card. to my thinking who in their right mind builds a bottom end and lets the customer install the cam? if you paid me for a short block build you're getting a cam and timing set installed, and degreed with a piece of paper that lists the cam specs and how it was installed (adv, ret, straight up). maybe he did good work, maybe the pistons are .040 in the hole and he was like: fool customer supplied these, might as well ship it and get paid, then just was all: yeah, the compression is whatever the mfg says it is.

then when the heads got snapped on somebody used whatever gaskets were available and now it's pushing like 8.2:1 compression.

anyway, to me, there's just a whole bunch of nebulous work and unverified, unanswered criticals floating around.

Have not read 6 pages......

- nothing wrong with the cam specs

- no, carb is not too big. Edel carb jets fit these carbs, so easy to fit smaller jets.

- did anybody check to see that the carb itself was reaching WOT??

- I never dyno a new engine, but many do . I think it is a bad move subjecting all those moving parts to high rpms & heat caused by the friction of new parts getting acquainted with each other...

- seems to something more fundamental to be down on so much power. Cam installed wrong, wiped lobes/lifters, lifter pre load etc.

- nothing wrong with the cam specs

- no, carb is not too big. Edel carb jets fit these carbs, so easy to fit smaller jets.

- did anybody check to see that the carb itself was reaching WOT??

- I never dyno a new engine, but many do . I think it is a bad move subjecting all those moving parts to high rpms & heat caused by the friction of new parts getting acquainted with each other...

- seems to something more fundamental to be down on so much power. Cam installed wrong, wiped lobes/lifters, lifter pre load etc.

You don't need a different carb. It's an AVS, the secondary air doors/flaps may need adjusted, may be sticking/not opening correctly, it is capable of way more power than that.....and can never be too "big" if the tension on those secondary flaps is set correctly.Engine on dyno and I'm not there. I can tell you it's a Carter AVS for 68 or 70 340 4 speed.

He said he degreed it so he'd know which cam it is, right? Unless he didn't degree it. We've not gotten a clear answer with numbers there, yet.he said that the carb was done by woodruff, which is known for putting out good work. and that the dyno operator swapped a carb they had kicking around, so you can extrapolate from that what you want-- and for me, that absolves any kind of carb issue; save for the mechanical operation of the carb on the dyno itself maybe hanging up or not allowing full throttle.

the cam is sus AF. they sent him the wrong one once, and then sent another. how'd he know it was wrong to begin with? who's to say the new one is right?

the engine builder is a wild card. to my thinking who in their right mind builds a bottom end and lets the customer install the cam? if you paid me for a short block build you're getting a cam and timing set installed, and degreed with a piece of paper that lists the cam specs and how it was installed (adv, ret, straight up). maybe he did good work, maybe the pistons are .040 in the hole and he was like: fool customer supplied these, might as well ship it and get paid, then just was all: yeah, the compression is whatever the mfg says it is.

then when the heads got snapped on somebody used whatever gaskets were available and now it's pushing like 8.2:1 compression.

anyway, to me, there's just a whole bunch of nebulous work and unverified, unanswered criticals floating around.

junkyardhero

Well-Known Member

at this point i question the veracity of story and the rectitude of the degree job.He said he degreed it so he'd know which cam it is, right? Unless he didn't degree it. We've not gotten a clear answer with numbers there, yet.

ir3333

Well-Known Member

really this is like going to a doctor and saying i've got a pain? So many things need to be checked and it

has been pointed out the dyno looks like it's running out of fuel. Cam lobes or worn out valve springs but who knows. Also suggested was dyno performance may be suspect. You have your work cut out for you!

has been pointed out the dyno looks like it's running out of fuel. Cam lobes or worn out valve springs but who knows. Also suggested was dyno performance may be suspect. You have your work cut out for you!

Kinda what I was sayin. LOLat this point i question the veracity of story and the rectitude of the degree job.

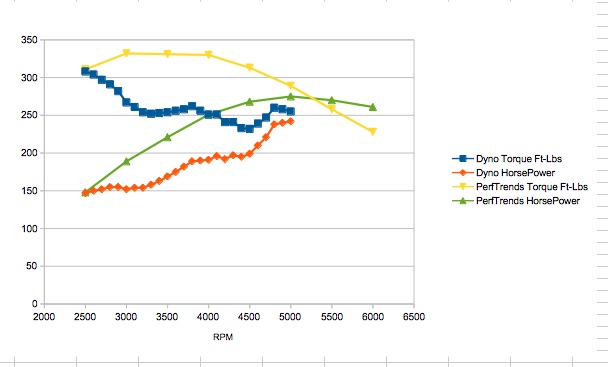

The Performance Trends software has a validated 1968 stock 340 example engine so I ran that and compared it to your data.... It matches up nicely at 2500 then it makes no sense. Cam timing is not going to give you that sort of a curve... personally I would start by seriously questioning the dyno and test itself unless you can find something seriously wrong with the engine (like it has lost a lobe on the cam or something like that)....

Almost like his curves are going backwards.The Performance Trends software has a validated 1968 stock 340 example engine so I ran that and compared it to your data.... It matches up nicely at 2500 then it makes no sense. Cam timing is not going to give you that sort of a curve... personally I would start by seriously questioning the dyno and test itself unless you can find something seriously wrong with the engine (like it has lost a lobe on the cam or something like that)....

View attachment 1716141949

Dartswinger70

Well-Known Member

I may be wrong but doesn't that look like late 340 HP specs? When the 318 was like 180 Horse the 340 was rated at 235 (the late 60s 318 spec...) you know basically smogger 340 Horsepower.

I may be wrong but doesn't that look like late 340 HP specs? When the 318 was like 180 Horse the 340 was rated at 235 (the late 60s 318 spec...) you know basically smogger 340 Horsepower.

You talking about my curve? That model was run with the parasitics that a later engine would have been tested to like waterpump, etc so it is a hybrid curve... early specs but running the test more like they had to in the later years (along with the lower performance specs of the early 70's). It is 10.5:1, 2.02 valves with measured flow data.

Those were my exact thoughts on doing it but based on results engine needs to come back apart. Cam selection and install was my doing.No … not really . Dyno time is so you can break in the engine , check for leaks and find performance issues before you spend days installing , tuning , diagnosing and then having to pull the engine againe and start all over .

although $800 seams spendy for a dyno shop that wont even rejet your carb muchless redegree your cam or set lash etc….

You then understand the long road as I. Glad to see your completed the task. I'm willing to bet you have a sweet running engine. Cats out of the bag with me so need to find the mental energy to correct the problem. Will be performing another pull today with smaller carb today but don't expect and different results. Thanks for the comments. I don't feel so alone.I think it took me about 2 or 3 years to get mine done. I did the same started from scratch. I started with a budget 318 and it was gonna have to he machined so I figured if I'm gonna pay a machine bill might as well go with a 360. I like you bought parts that was wrong for the combo ended up changing the combo a few different times due to parts I couldn't get during the pandemic! Three sets of pistons and about 2 camshafts later It started setting in just how much planning needs to be made before hand lol my engine ended up as a 360 .06 over refurbished stock crank rods and kb 107 pistons ported heads valve job and comp springs voodoo cam factory 71 340 intake and thermoquad carb. It makes 175 psi cylinder pressure and about 10.2 scr. I can't recall the dcr. Somewhere around 9 tho. I wish I had the means to dyno it and tune it on a dyno I have no idea what it makes it might be similar to yours for all I know but I do know it's alot of fun.

-