If all 8 cylinders are at least .034 run it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 340 build

- Thread starter MoparMark91

- Start date

-

MoparMark91

Well-Known Member

Yeah so maybe i will be alright with what i have i just have read more clearance is recommended before. These are icon 741 forged pistons so leaning toward i think ill he okay as long as that gasket didmt compress more due to the head studs or anything lol

I just dont want to cut it too close with the clearance

The blue permatorque are .050? I always heard thr compressed same as 1008 .039

I just dont want to cut it too close with the clearance

The blue permatorque are .050? I always heard thr compressed same as 1008 .039

Last edited:

If all cylinders are at least .034, Run it.

Now I'm repeating myself but so are you.

Now I'm repeating myself but so are you.

Wyrmrider

Well-Known Member

I'm runing .025 in one motor several at .030

I know you are but so am I

I know you are but so am I

nm9stheham

Well-Known Member

1008 = .039"Yeah so maybe i will be alright with what i have i just have read more clearance is recommended before. These are icon 741 forged pistons so leaning toward i think ill he okay as long as that gasket didmt compress more due to the head studs or anything lol

I just dont want to cut it too close with the clearance

The blue permatorque are .050? I always heard thr compressed same as 1008 .039

8553PT = approx .050"

Right out of the mfr's specs....

I went up to a bit over .040" due to similar caution, and the fact that the machining left a top-to-bottom slope on the deck that I had to get corrected (partially successful). Next time, I'll probably just let it ride at a bit tighter.

MoparMark91

Well-Known Member

Thank you all for help i decided im going to run it, im just very cautious as this is the first time performance motor. As u can see my valve clearance is fine and i measured twice the piston height out of block so hope ill be good with these 1008 cause i doubt id have proper ra for a cometic lol this weekend i will be adding pushrods and adjusting rockers and installing intake, i was mainly worried when things warm up and possibly stretch or get worn in its life if that little clearance will come back to bite me in the *** lol

Last edited:

MoparMark91

Well-Known Member

Updated

MoparMark91

Well-Known Member

A little update on build, balancer is on and i believe it is flush tell me what u guys think i used installer, and put the rockers on and pushrods in still need to do a couple things. Modify the valley pan bolts since the intake hits it and prevents it from sitting flush, didnt realize or think of this issue so ill use low profile flat head bolts. But mocked up the intake and take a look guys

yellow rose

Overnight Sensation

It looks like it's all the way on, but it's hard to tell because damper thickness varies. Look and see if the pulleys line up. That will tell you for sure.

Now, I'm just askin here, so don't take this the wrong way, scooter........but you have some really nice parts and some beautiful machine work goin on there. "Loonimum heads" as an old friend of mine used to call um, lol, really nice pistons, lots of dollars elsewhere, so I gotta ask, why are you running run of the mill head gaskets? No way in hell itself would I do that. I'd be callin Cometic, or even lookin at a nice copper gasket. I got nothin against FelPro, they make good stuff, but you're building better than "good". jmo.

MoparMark91

Well-Known Member

So you got a point there rusty, so i did think about cometic but...my ra i didnt believe would be good enough on the surface, and ive ran felpro before and no problems, along with others that sware by them. My block did get machined but i dont think it would if bern suffice for the gaskets, this is my first performance build so i figured felpro has done me goid in the past why not slap em on, plus i have to slow down and wanted to budget somethings cause i still need a new rear end lol......also the wife came across my receipt stack for my build .Now, I'm just askin here, so don't take this the wrong way, scooter........but you have some really nice parts and some beautiful machine work goin on there. "Loonimum heads" as an old friend of mine used to call um, lol, really nice pistons, lots of dollars elsewhere, so I gotta ask, why are you running run of the mill head gaskets? No way in hell itself would I do that. I'd be callin Cometic, or even lookin at a nice copper gasket. I got nothin against FelPro, they make good stuff, but you're building better than "good". jmo.

D'OH!

Honestly wish i could run em withoutout worrying about the ra

Last edited:

MoparMark91

Well-Known Member

Damn it now u got me thinking lol

yellow rose

Overnight Sensation

So you got a point there rusty, so i did think about cometic but...my ra i didnt believe would be good enough on the surface, and ive ran felpro before and no problems, along with others that sware by them. My block did get machined but i dont think it would if bern suffice for the gaskets, this is my first performance build so i figured felpro has done me goid in the past why not slap em on, plus i have to slow down and wanted to budget somethings cause i still need a new rear end lol......also the wife came across my receipt stack for my build .

D'OH!

Honestly wish i could run em withoutout worrying about the ra

FWIW, there isn't a gasket out there that likes a rough surface. Not one I can think of. The idea of a rough surface "biting" into the gasket is just plain nonsense.

That said, some gaskets are much more forgiving of a rough surface. The Fel Pro is one of them. MLS gaskets really need a mirror finish. They can be a bit rougher, but not much.

The composite gaskets don't really don't like a rough surface either. When those fail from a wrong surface finish you'll find many or most of the head bolts loose. Most people blame the gasket for failing, but the gasket isn't really at fault. The rough surface literally grinds the gasket down to the point the fasteners are now loose.

People don't think that the head and block don't move. But they do. More than most think. All aluminum engines have the most movement, and bi metal engines are very hard on gaskets.

Not only do the heads move around on the block, every time a cylinder fires, the head literally lifts off the block. Every single time. So the gasket has to move in 3 axes.

nm9stheham

Well-Known Member

Don't... what you have works and is reliable. Raced and raced and raced on standard head gaskets. Good flat surfaces are more important IMHO.Damn it now u got me thinking lol

The only attribute I can think of for Cometics is their resitsance to blowing out, and some good variability in setting thickness and hole size. But your SCR/DCR is set fine as it; tune it right and be happy.

BTW, the damper looks good. If it seated firmly when installing, and you got the 135 ft-lbs of torque on the snout bolt, then it sounds all right.

Don't... what you have works and is reliable. Raced and raced and raced on standard head gaskets. Good flat surfaces are more important IMHO.

The only attribute I can think of for Cometics is their resitsance to blowing out, and some good variability in setting thickness and hole size. But your SCR/DCR is set fine as it; tune it right and be happy.

BTW, the damper looks good. If it seated firmly when installing, and you got the 135 ft-lbs of torque on the snout bolt, then it sounds all right.

If this guy here ^^^^^ thinks you'll be ok with them FePros, then run them. I was just lookin at all that money you got in everything and was wonderin if there might be a better choice. Cometic will make you any gasket for any surface roughness, but if these guys think the FelPros will do it, then I would run them.

MoparMark91

Well-Known Member

Thanks guys, i will be probably staying with my felpros but just curious how are the cometics? Would they have sealing problems on application like mine unsurfaced edelbrock heads and decked/surfaced block?

nm9stheham

Well-Known Member

I can tell you that we have a set of Cometics sealing fine so far on a 340 with Edelbrocks with no particularly spec'd surfacing work on either head or block. Heads new as surfaced from Edelbrock, and block surfaced to be very flat at a local shop. But not a ton of miles on the engine. ARP head bolts, not studs. Carefully torqued down in steps. Heads off and back on once wiht the same Cometics. I only went to Cometics to tweak the quench/squish gap.

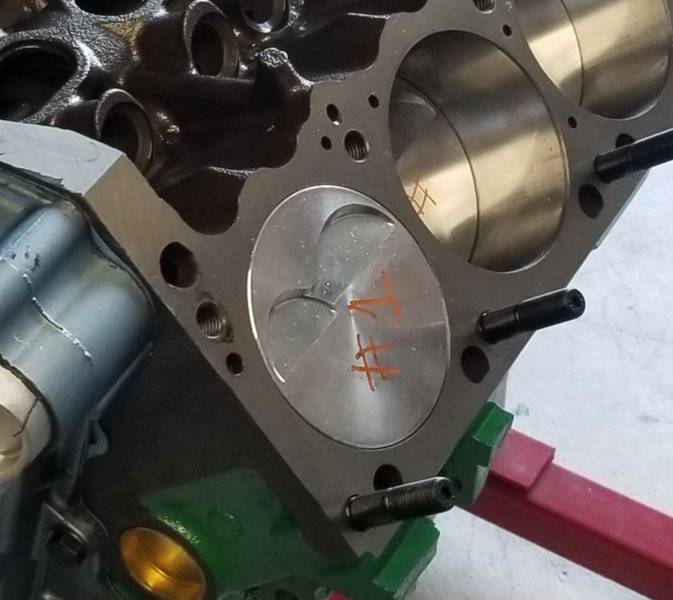

Attached is the best pix I have of that block's surfacing work; Maybe YR can look and comment on how smooth this surface is.

I never have asked what particular surface my local shop puts on here in VA; the owner has built lots and lots of race engines (8's, 6's and 4's) for the local track, so they may just know how to put on a (finer?) finish. IDK. I've had machine work done one my rally engines are about 4 different shops in VA, IN, and OH over the years, and never had a head gasket issue except 1, and rally cars see a lot of heat cycles (but probably not the same peak power levels in terms of HP per ci). The head was warped in that 1 case. Otherwise, all standard kit gaskets, Permatorques and composition types, even with 14-15 psi boost..... no issues as long as the parts are good and flat.

And yes the bolts/studs have to stretch a miniscule amount to take the pressure on each cylinder firing. But IMHO it is a matter of degree. If they stretch .00001", then probably not any issue. We're not running top fueler engines here. At what HP level, this become more of an issue is something I don't know the answer to.

Attached is the best pix I have of that block's surfacing work; Maybe YR can look and comment on how smooth this surface is.

I never have asked what particular surface my local shop puts on here in VA; the owner has built lots and lots of race engines (8's, 6's and 4's) for the local track, so they may just know how to put on a (finer?) finish. IDK. I've had machine work done one my rally engines are about 4 different shops in VA, IN, and OH over the years, and never had a head gasket issue except 1, and rally cars see a lot of heat cycles (but probably not the same peak power levels in terms of HP per ci). The head was warped in that 1 case. Otherwise, all standard kit gaskets, Permatorques and composition types, even with 14-15 psi boost..... no issues as long as the parts are good and flat.

And yes the bolts/studs have to stretch a miniscule amount to take the pressure on each cylinder firing. But IMHO it is a matter of degree. If they stretch .00001", then probably not any issue. We're not running top fueler engines here. At what HP level, this become more of an issue is something I don't know the answer to.

MoparMark91

Well-Known Member

I appreciate a lot i do, i nust have thoight about the cometic for the exact reason of being able to tweak the quench even better and have always wanted to try cometic honestly. In the picture it looks pretty good im trying to compare it too my picture of my block since im not next to it. I zoomed in on the surface of my block and i can see very fine lines but just curious if it would seal up. I am also running arp head studs,Maybe ill stop by my machinist and talk to him about if he mills it to a certain grit or something?I can tell you that we have a set of Cometics sealing fine so far on a 340 with Edelbrocks with no particularly spec'd surfacing work on either head or block. Heads new as surfaced from Edelbrock, and block surfaced to be very flat at a local shop. But not a ton of miles on the engine. ARP head bolts, not studs. Carefully torqued down in steps. Heads off and back on once wiht the same Cometics. I only went to Cometics to tweak the quench/squish gap.

Attached is the best pix I have of that block's surfacing work; Maybe YR can look and comment on how smooth this surface is.

I never have asked what particular surface my local shop puts on here in VA; the owner has built lots and lots of race engines (8's, 6's and 4's) for the local track, so they may just know how to put on a (finer?) finish. IDK. I've had machine work done one my rally engines are about 4 different shops in VA, IN, and OH over the years, and never had a head gasket issue except 1, and rally cars see a lot of heat cycles (but probably not the same peak power levels in terms of HP per ci). The head was warped in that 1 case. Otherwise, all standard kit gaskets, Permatorques and composition types, even with 14-15 psi boost..... no issues as long as the parts are good and flat.

And yes the bolts/studs have to stretch a miniscule amount to take the pressure on each cylinder firing. But IMHO it is a matter of degree. If they stretch .00001", then probably not any issue. We're not running top fueler engines here. At what HP level, this become more of an issue is something I don't know the answer to.

View attachment 1715396159

yellow rose

Overnight Sensation

I can tell you that we have a set of Cometics sealing fine so far on a 340 with Edelbrocks with no particularly spec'd surfacing work on either head or block. Heads new as surfaced from Edelbrock, and block surfaced to be very flat at a local shop. But not a ton of miles on the engine. ARP head bolts, not studs. Carefully torqued down in steps. Heads off and back on once wiht the same Cometics. I only went to Cometics to tweak the quench/squish gap.

Attached is the best pix I have of that block's surfacing work; Maybe YR can look and comment on how smooth this surface is.

I never have asked what particular surface my local shop puts on here in VA; the owner has built lots and lots of race engines (8's, 6's and 4's) for the local track, so they may just know how to put on a (finer?) finish. IDK. I've had machine work done one my rally engines are about 4 different shops in VA, IN, and OH over the years, and never had a head gasket issue except 1, and rally cars see a lot of heat cycles (but probably not the same peak power levels in terms of HP per ci). The head was warped in that 1 case. Otherwise, all standard kit gaskets, Permatorques and composition types, even with 14-15 psi boost..... no issues as long as the parts are good and flat.

And yes the bolts/studs have to stretch a miniscule amount to take the pressure on each cylinder firing. But IMHO it is a matter of degree. If they stretch .00001", then probably not any issue. We're not running top fueler engines here. At what HP level, this become more of an issue is something I don't know the answer to.

View attachment 1715396159

That's a good finish. That will easily seal Cometics.

yellow rose

Overnight Sensation

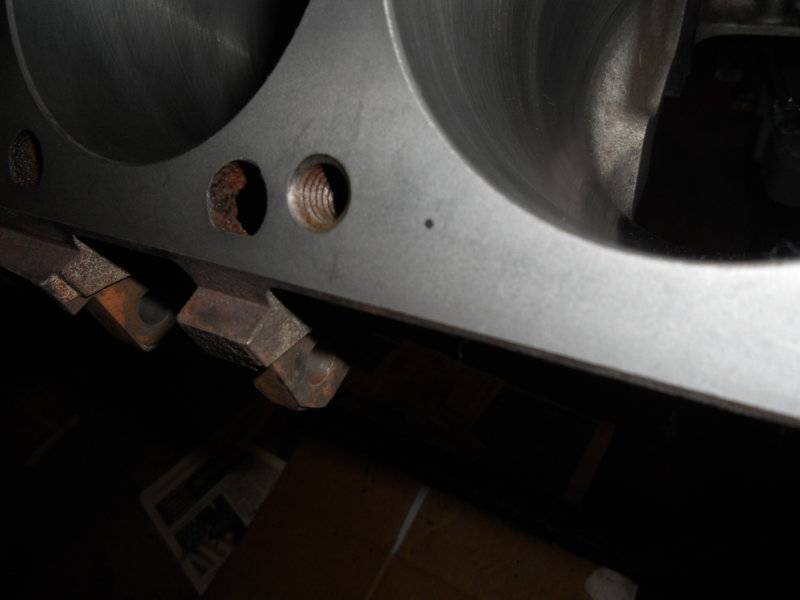

I appreciate a lot i do, i nust have thoight about the cometic for the exact reason of being able to tweak the quench even better and have always wanted to try cometic honestly. In the picture it looks pretty good im trying to compare it too my picture of my block since im not next to it. I zoomed in on the surface of my block and i can see very fine lines but just curious if it would seal up. I am also running arp head studs,Maybe ill stop by my machinist and talk to him about if he mills it to a certain grit or something?

View attachment 1715396212

Ok, that is not what I think of when I say rough surface finish. Your surface looks like what you get with a stone and there is nothing wrong with that.

It's not a mirror finish, but that will seal Cometics too.

Maybe I should go see if I can find what I'm mean by rough surface.

I'm all for mirror finish. My heads and block were damn near mirror finish and I used Fel-Por gaskets. They are leaking yet. I'm sure when I get home tomorrow they will be puking coolant right on the floor now that I typed typed that (thankfully it's Evans coolant so that's only 40 bucks plus shipping a gallon).

I've also finished and ton of surfaces with a stone. And none of those ever lost a Cometic. One was a 300 inch blown gas Comp Eliminator engine. 10:71 blower on gas. He was shifting at 9400 and crossing at 10,200. I know because I've seen downloads from 100 of his runs. Ex Pro Stock guy. Probably the best natural driver I've ever seen.

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,329

- Reaction score

- 1,970

If you go the felpro, I would retorque them. I have had issues when I didn’t. Torque them then let them sit over night and back each off a 1/4 turn and retorque in order. I agree you surface would be fine for cometics. Search what grit the recommended RA converts to. It will give you a better understanding of how smooth it needs to be. I run cometics no issues. To be honest I think there was some confusion of water leaks with cometics on LA’s and it wasn’t surface finish it was actually the wrong gasket. IIRC you needed to run a w2 gasket if using a r block or something like that. Its been years since reading up on it.

nm9stheham

Well-Known Member

Yes I always re-torque regardless on anything even semi-performance.If you go the felpro, I would retorque them.

Of course they will LOL! BTW I think you meant to say 'They are NOT leaking yet.'......I'm all for mirror finish. My heads and block were damn near mirror finish and I used Fel-Por gaskets. They are leaking yet. I'm sure when I get home tomorrow they will be puking coolant right on the floor now that I typed typed that (thankfully it's Evans coolant so that's only 40 bucks plus shipping a gallon).

I've also finished and ton of surfaces with a stone. And none of those ever lost a Cometic. One was a 300 inch blown gas Comp Eliminator engine. 10:71 blower on gas. He was shifting at 9400 and crossing at 10,200. I know because I've seen downloads from 100 of his runs. Ex Pro Stock guy. Probably the best natural driver I've ever seen.

BTW, what is you objective in using the Evan's coolant?

yellow rose

Overnight Sensation

Yes I always re-torque regardless on anything even semi-performance.

Of course they will LOL! BTW I think you meant to say 'They are NOT leaking yet.'......

BTW, what is you objective in using the Evan's coolant?

Never changing it. The fact that it runs with literally zero pressure. I like the fact that it actually pulls more heat out of the engine.

I'm very happy with it. If it did nothing but last forever I'd use it. But the big selling point was near zero system pressure. I can pull the cap at full temp and it doesn't blow all over me and scald me. And it's easier on hoses and soft plugs.

nm9stheham

Well-Known Member

OK, thanks. I've yet to go down that road... if I ever will.

FWIW, it actually has lower heat conduction than a standard AF-water mix so will run a bit hotter. But the fact that it has a much higher boiling point is probably of value in keeping the chambers a tad cooler when you push things hard.

FWIW, it actually has lower heat conduction than a standard AF-water mix so will run a bit hotter. But the fact that it has a much higher boiling point is probably of value in keeping the chambers a tad cooler when you push things hard.

yellow rose

Overnight Sensation

OK, thanks. I've yet to go down that road... if I ever will.

FWIW, it actually has lower heat conduction than a standard AF-water mix so will run a bit hotter. But the fact that it has a much higher boiling point is probably of value in keeping the chambers a tad cooler when you push things hard.

Exactly. Even though water has better heat conduction, it also steams off quicker. That's how you get localized steam pockets and lose cooling effectiveness.

I found a website that had some testing of straight water coolant. It was interesting what they found. Essentially, they found that the more steam pockets that formed, the lower the system pressure became, effectively lowering the boiling point of the water, and then you get more steam pockets. It was a vicious circle.

I printed that all off but it either went with the W5 heads when I sold them, or Ive lost them. I'll never forget the year...it was 2000 and I was just starting out with the W5 stuff. I wasn't going to pull coolant from in between the exhaust valves on the intake side of the heads like the W5's are drilled to do.

Then I found that article and I did it. It was a ROYAL PITA to make the hosed clear my throttle linkage for the tunnel ram. But I did it because the article stated that on cylinder heads with side by side exhaust valves (SBC, SBM, BBM etc) that's where the first steam pockets formed. Then it was at the number 7 exhaust valve area because it fired right after number 5 (another reason to use the 2-3 4-7 swap firing order) and then I forget what happened.

A lot of good info has been lost over the years because it just gets ate up in the interweb somewhere. Somewhere there is a video of a dyno session of a 408 I did that went 545 HP at 5200. Have no idea where that went of how to find it.

-