You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steve's 70 Gen III Hemi Build

- Thread starter SteveAle

- Start date

-

SteveAle

Well-Known Member

It is looking great

Thank you very much, cars coming along slowly

Great progress.. If you don't mind me asking.. What camera are you using for your pictures on this thread? Thankyou

SteveAle

Well-Known Member

Great progress.. If you don't mind me asking.. What camera are you using for your pictures on this thread? Thankyou

I am using a Sony Cybershot its an older camera only 10.1 megapixel

JBrian

Well-Known Member

This is just another outstanding GEN III Duster build like several others going on across the country.

This is just another outstanding GEN III Duster build like several others going on across the country.

x 10....nice work!

and thanks for keeping us updated

SteveAle

Well-Known Member

Thanks for all the support :cheers: I hope to have some more updates soon. It is getting time to start putting some of the pieces back on just so I can see what kind of room I have to work with.

I got a 5 gallon bucket of wiring harness and a couple computer boxes I have to install and make invisible "if possible" that go with the engine.

Let the fun continue..

I got a 5 gallon bucket of wiring harness and a couple computer boxes I have to install and make invisible "if possible" that go with the engine.

Let the fun continue..

DaleC

New Member

Awesome car! Following...

813Demon340

Well-Known Member

Great Duster build! Thats going to be quite the screamer with that motor. Keep up the great progress!

SteveAle

Well-Known Member

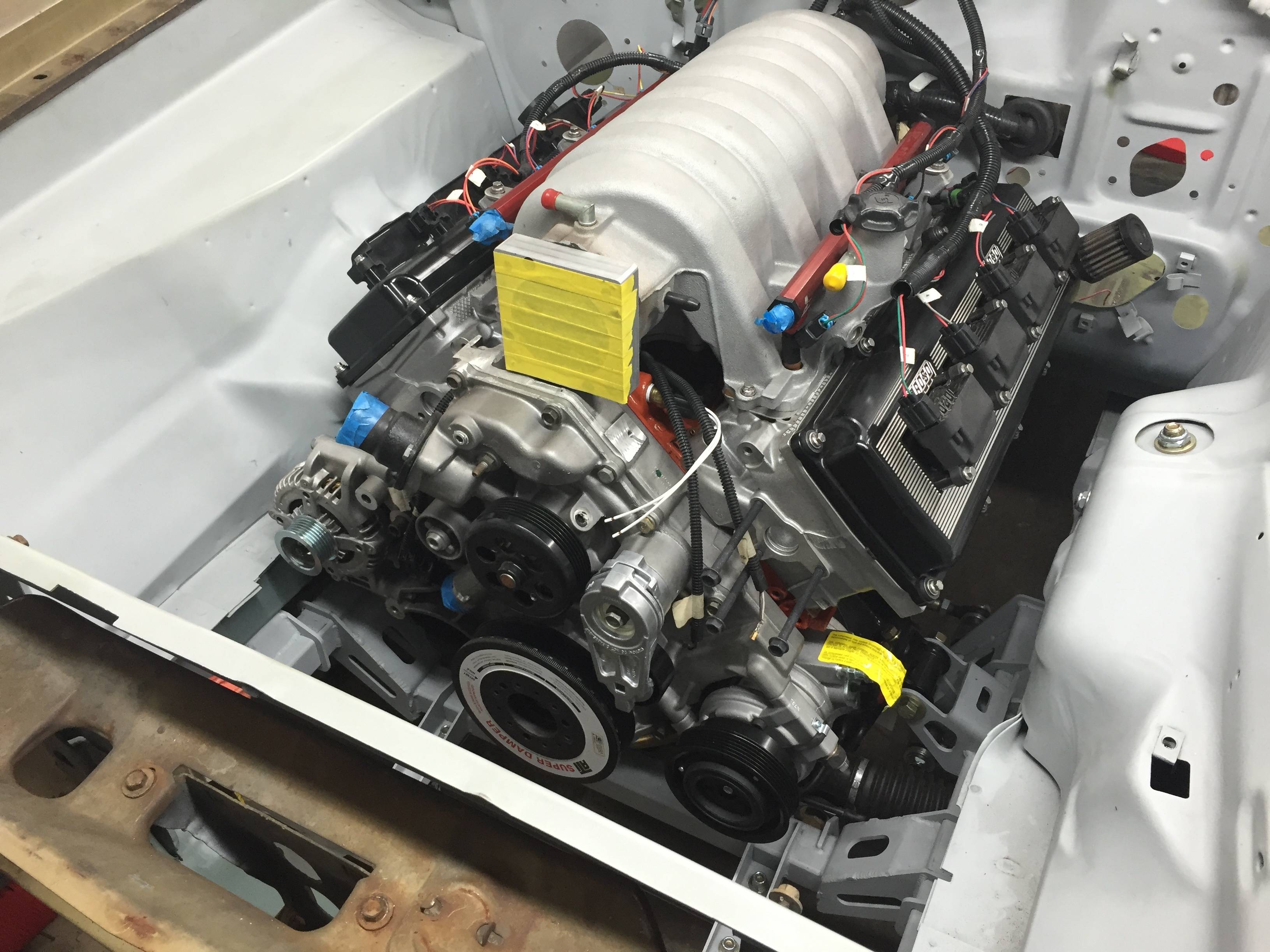

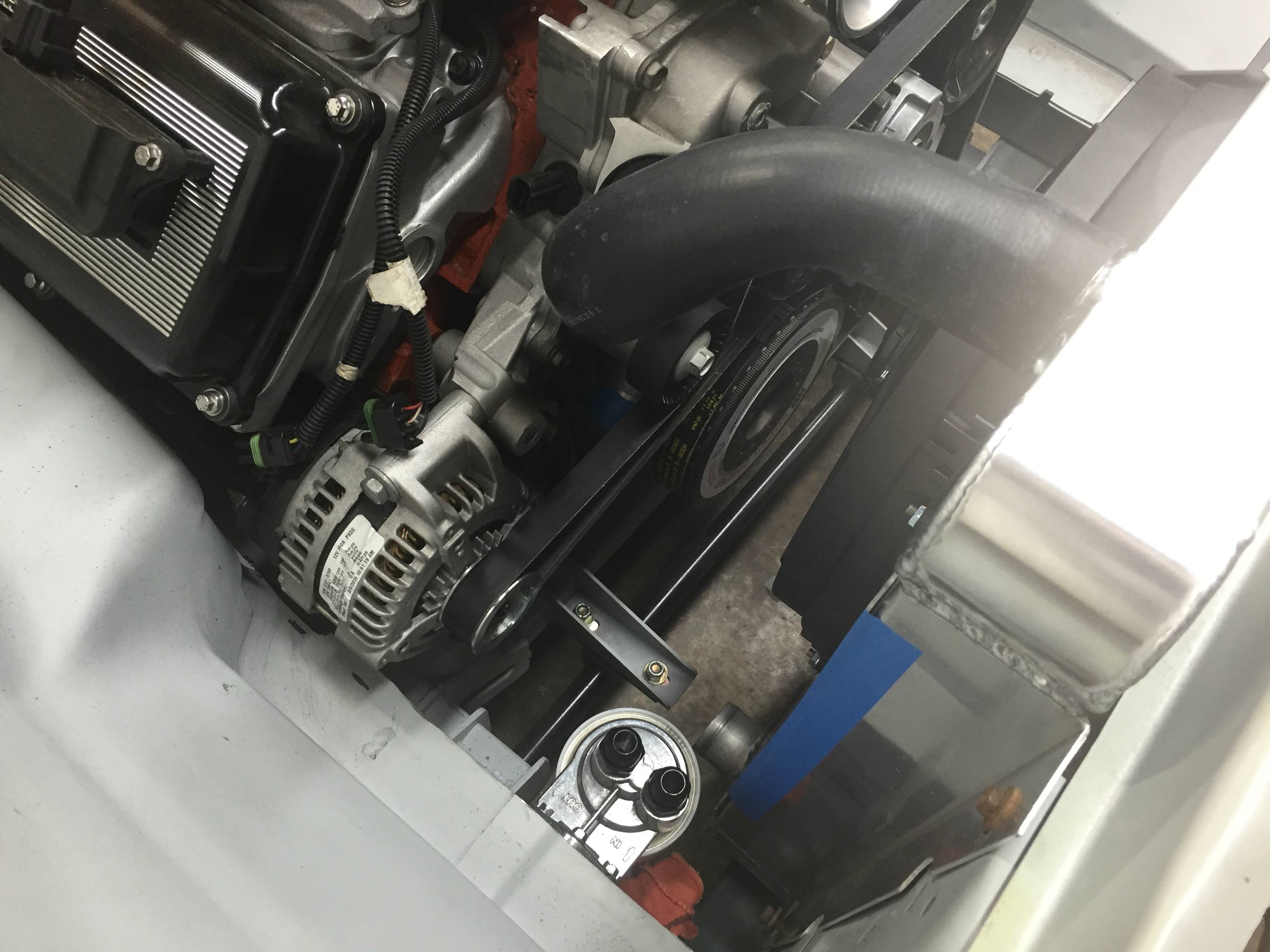

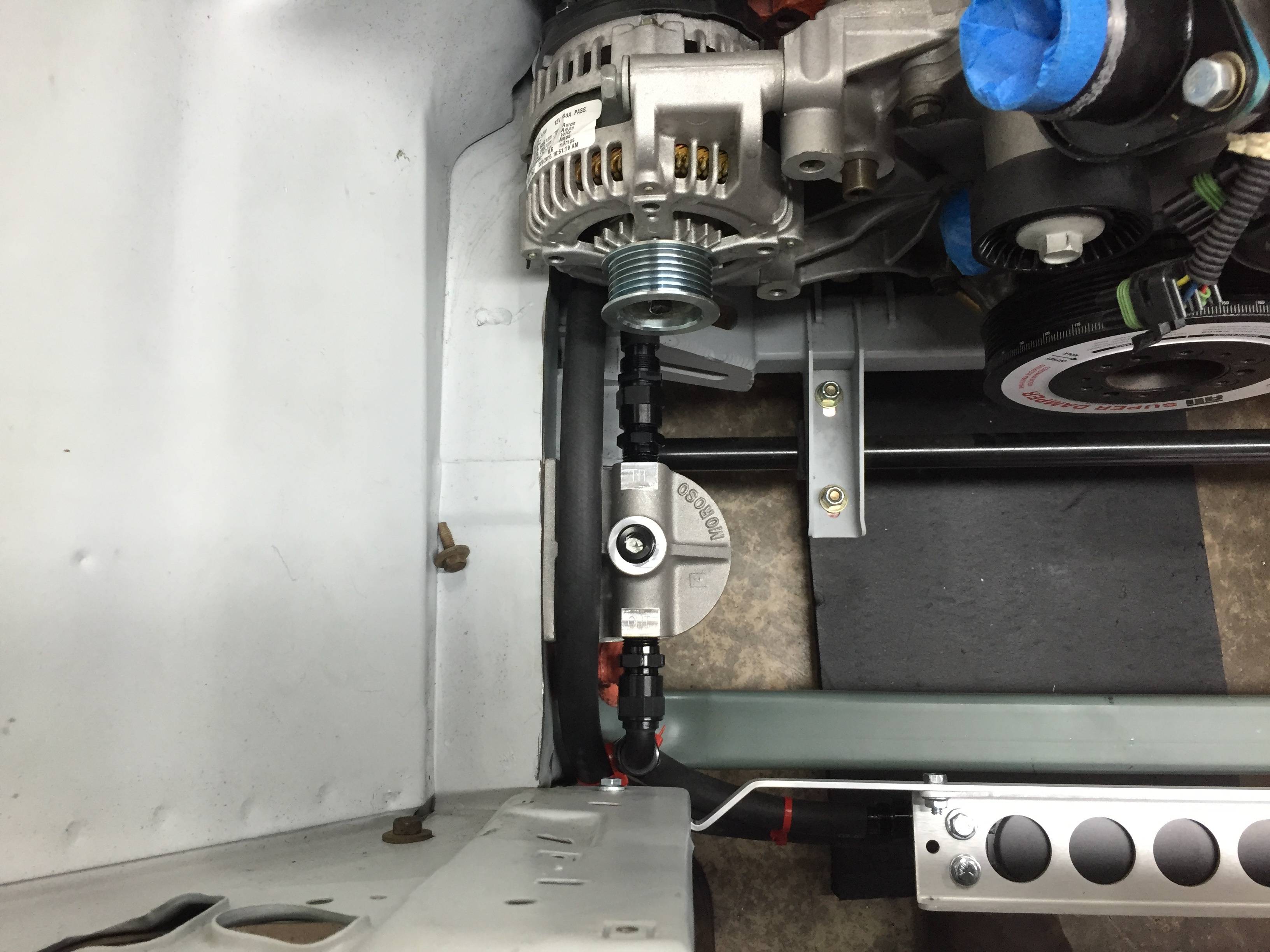

Been mocking up the engine compartment. Trying to fit everything into place and get it ready for final assembly. I had to clearance the lip off the passenger frame rail to provide the needed clearance for the 160 amp alternator that I plan to run. AC compressor fit rather well in the frame. I will need to clearance the motor mount bracket just a little but only so that the AC compressor has some vibration clearance.

SteveAle

Well-Known Member

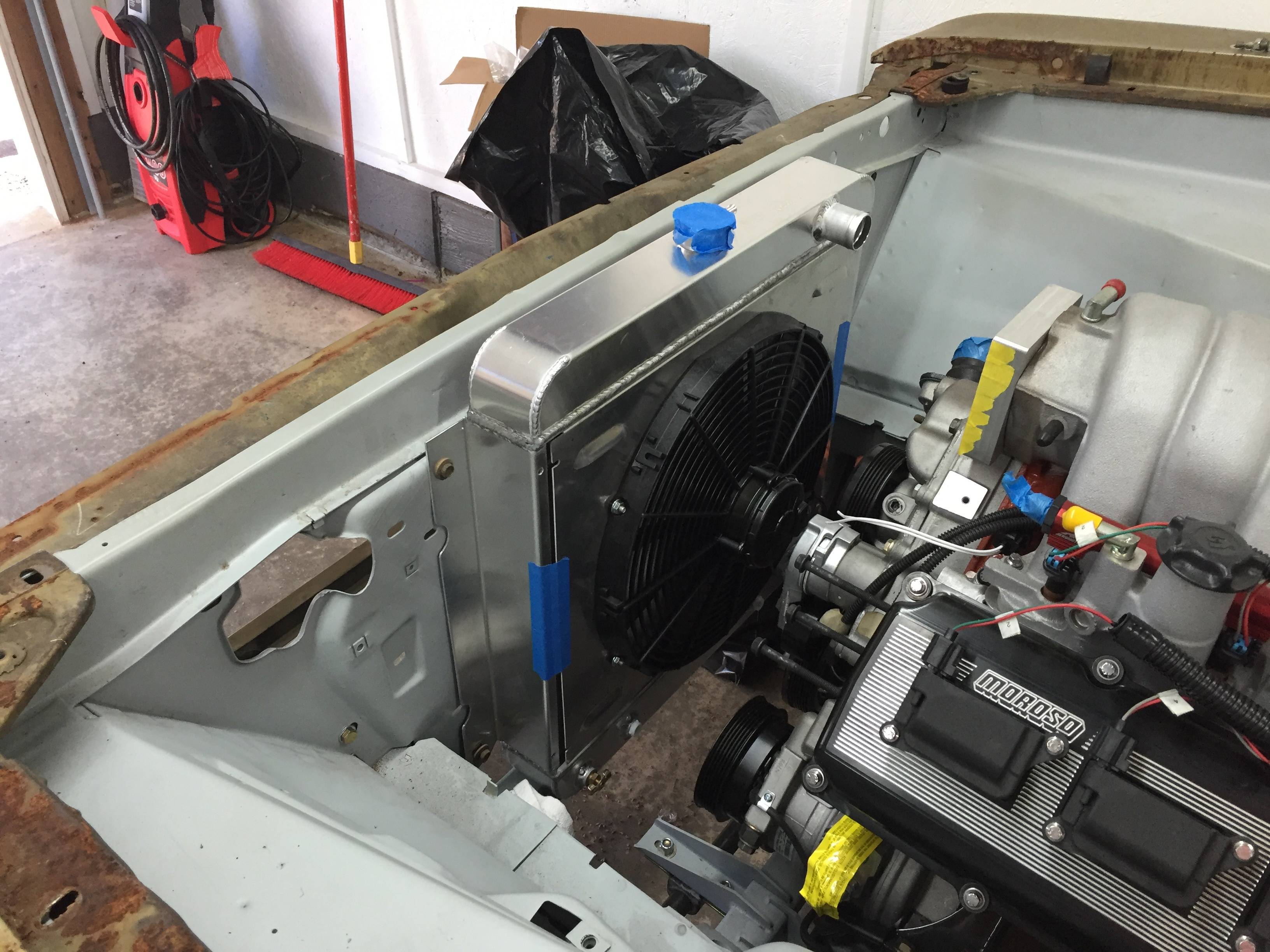

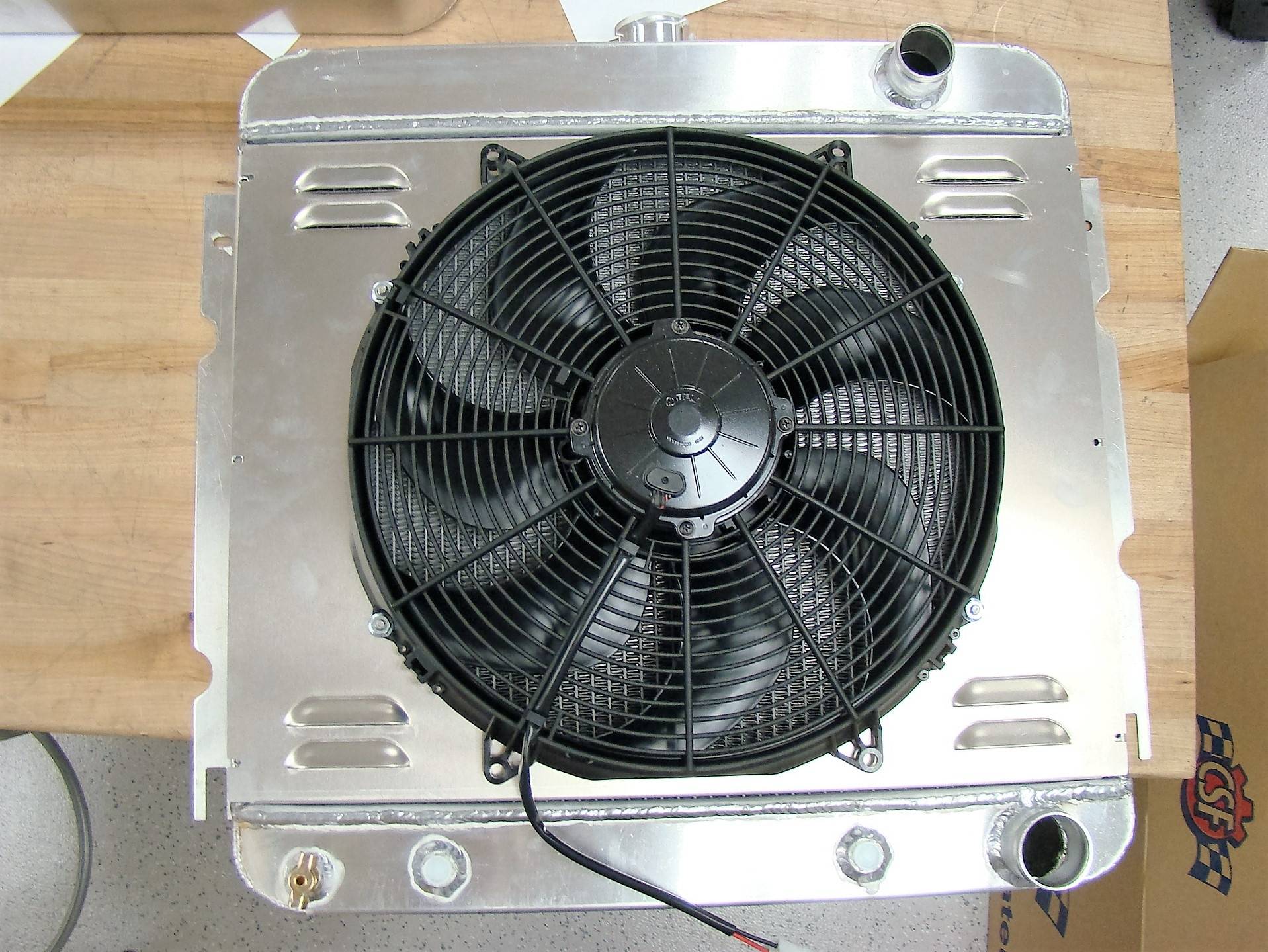

Ordered my radiator and cooling fan assembly. I went with the Northern radiator and fan combo. Once I got the radiator in the car I noticed the fan didnt fit at all. I assumed it was just a "recommended fit" and that I was gonna have to make a new bracket for the fan, but after several email and exchanging of photos. We got it right.

SteveAle

Well-Known Member

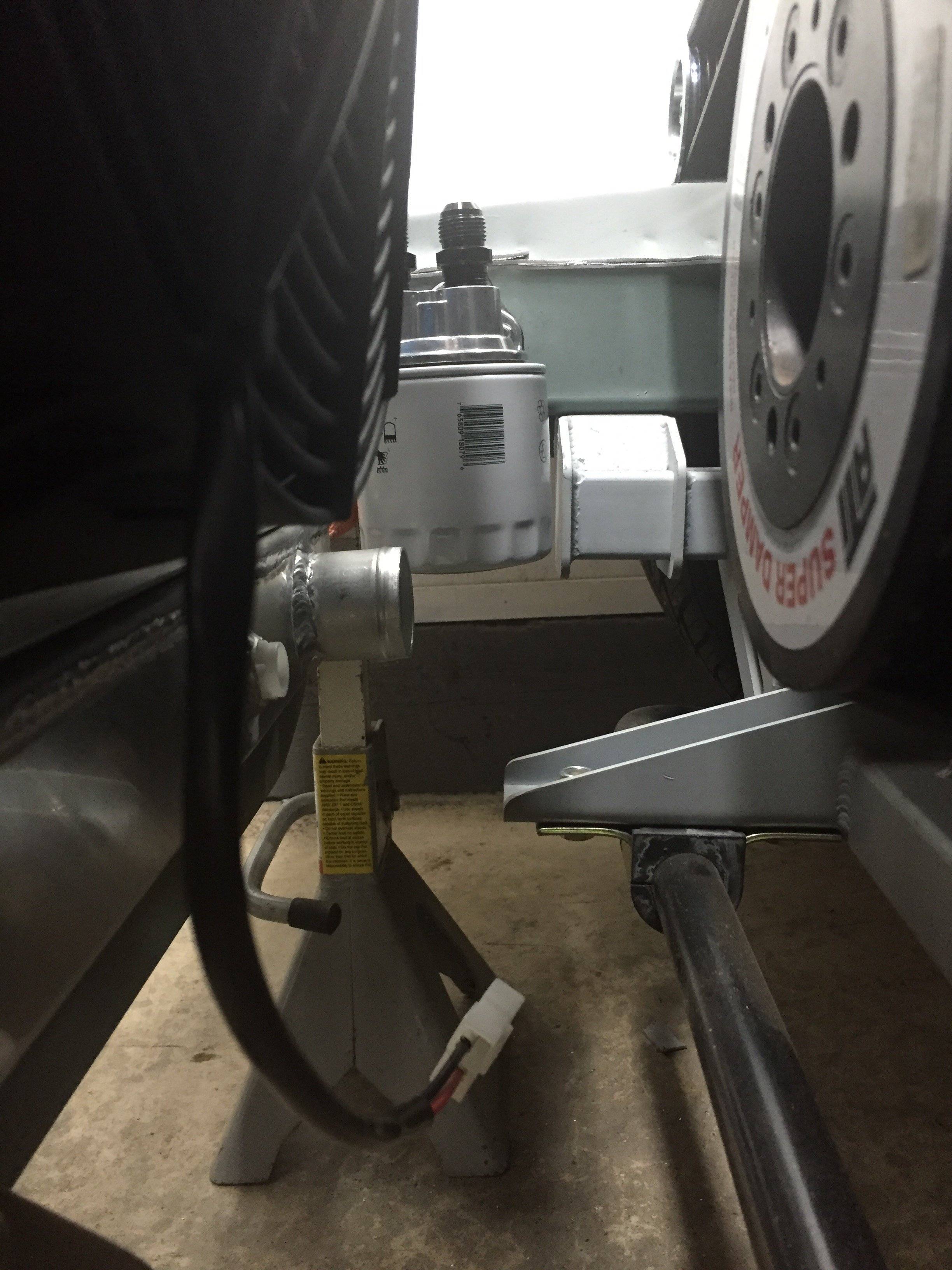

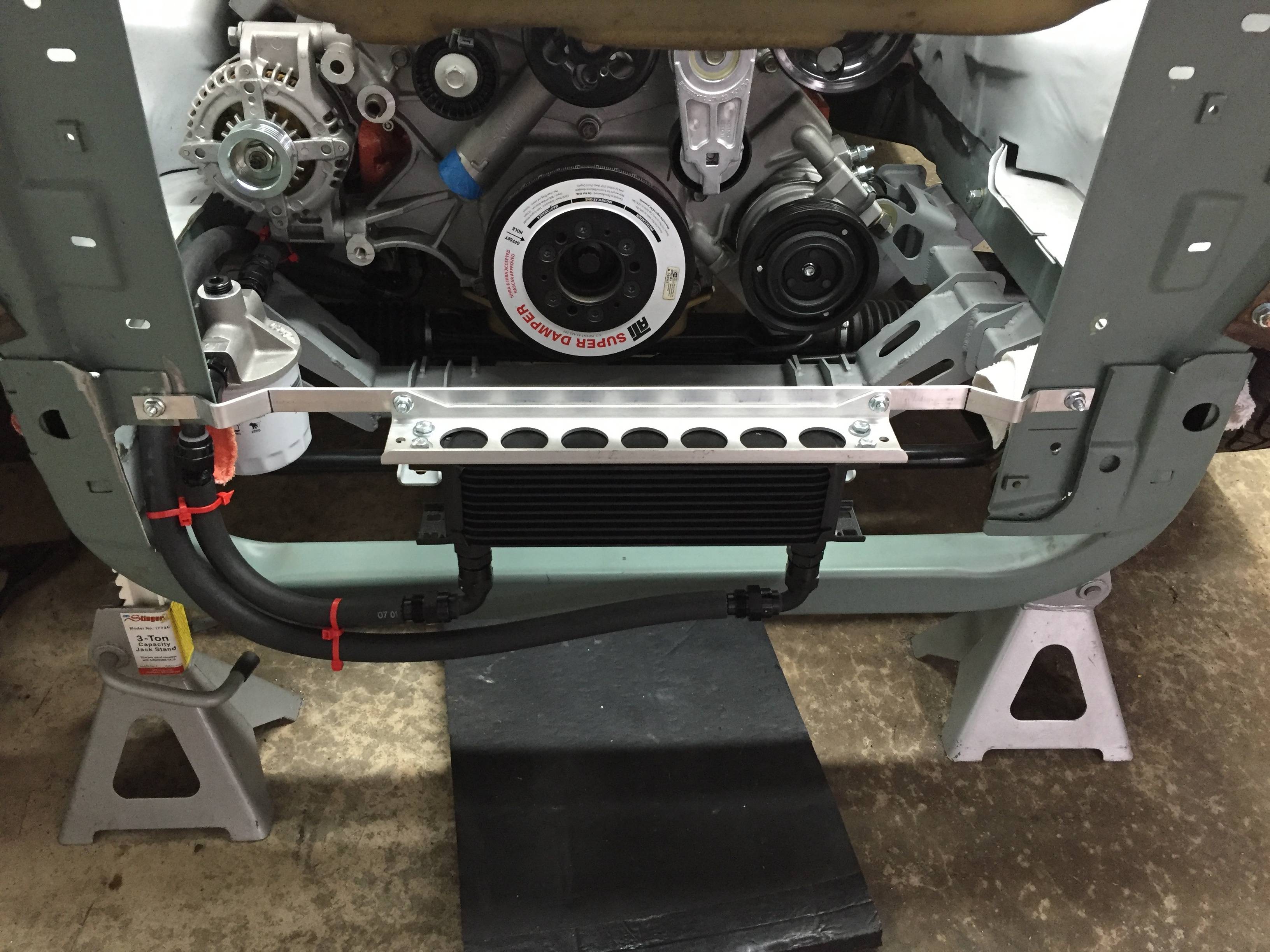

Once I had got the radiator, fan and hoses worked out. I have moved on to the engine oil cooler and filter mounting. I found a nice little spot on the frame rail just between the radiator and the k-member. Almost like it was made for it.

SteveAle

Well-Known Member

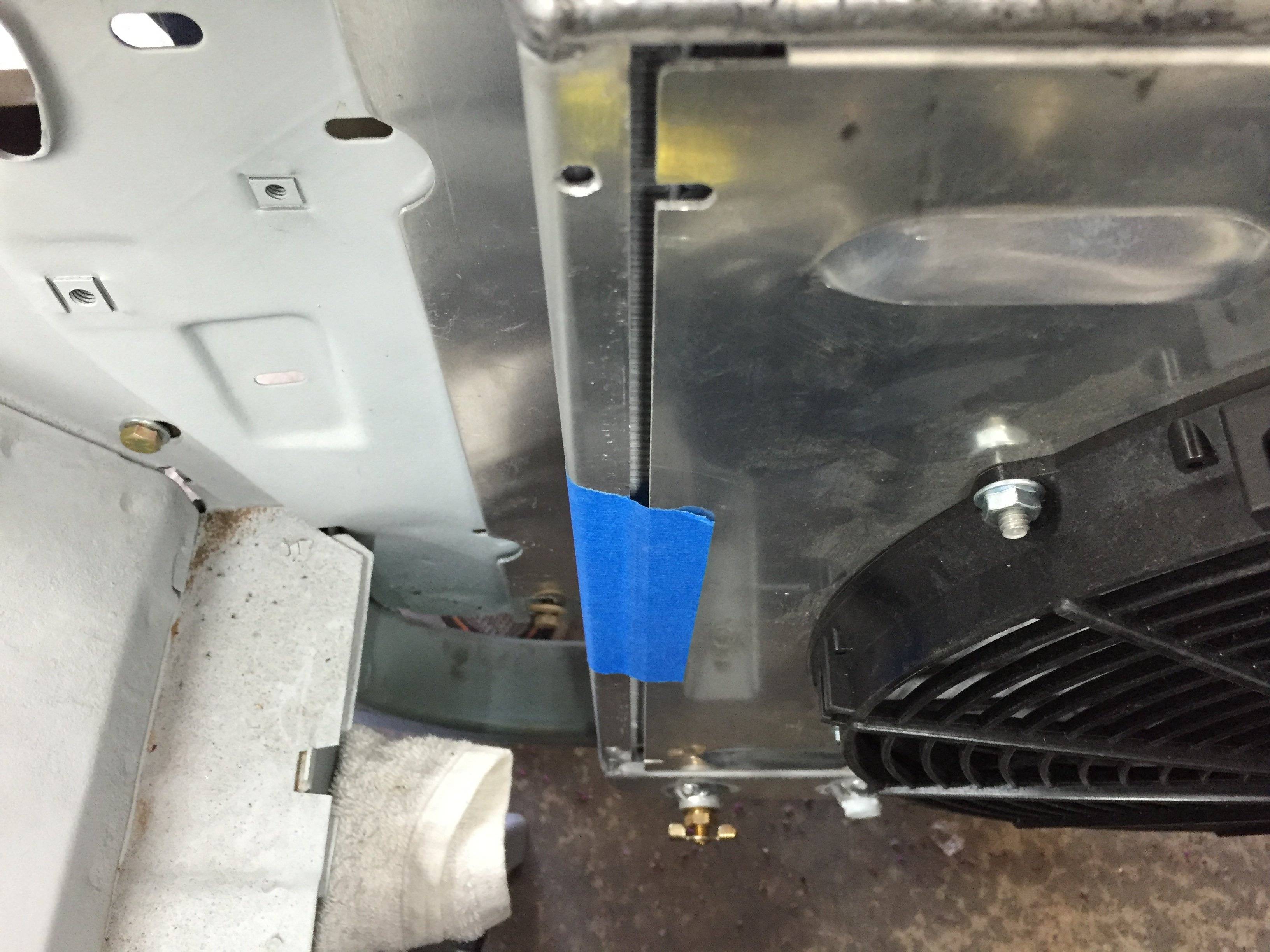

Only problem thou was I couldnt get hoses to run like I wanted them to. The mount I was using required the hoses to cross over each other in ways I didnt like. More of an eyesore than I liked.

SteveAle

Well-Known Member

I finally decided to go with a straight in and out moroso mount and cut out the bottom right side of radiator support so I could come right through the front and clean it up some.

SteveAle

Well-Known Member

I now have cut out the radiator support. Mocked up my oil cooler hose with some heater hose. Got my cooler mount made and test fit it all. I think they will do just fine. Now all I need to do is make the actual line and clamp then in place, once I get to final assembly that is.

Outstanding....sorry about the clearance on the A/C compressor. .... it is tight, but I thought I had enough space. Please email me a close up when you get the chance.

hemidenny@rocketmail.com

hemidenny@rocketmail.com

JBrian

Well-Known Member

I like that bracket for the oil cooler. What size radiator do you have, 22" or 26"?

SteveAle

Well-Known Member

Outstanding....sorry about the clearance on the A/C compressor. .... it is tight, but I thought I had enough space. Please email me a close up when you get the chance.

Will do Denny, I got motor back out now to do some break in and engine tuning on the engine dyno, but will send you pictures soon as its back in.

I like that bracket for the oil cooler. What size radiator do you have, 22" or 26"?

Thank you on the bracket. I used the 22.

SteveAle

Well-Known Member

Updating my slow building process. Wow it takes alot of money to do this

Alot has happened since my last post in July. I went to the dyno with my engine to do some break in and tuning to get it right before I got it all put together. Ran into some problems with the FAST set up, bad box so with all the efforts it was a no go on the dyno. So had to bring it back to the shop..

But I decided to take that time to tear down and change engine color and replace the remaining fastener with ARP stuff. I also decided to install a new Holley EFI set up, FAST throttle body and a couple other little changes.

Alot has happened since my last post in July. I went to the dyno with my engine to do some break in and tuning to get it right before I got it all put together. Ran into some problems with the FAST set up, bad box so with all the efforts it was a no go on the dyno. So had to bring it back to the shop..

But I decided to take that time to tear down and change engine color and replace the remaining fastener with ARP stuff. I also decided to install a new Holley EFI set up, FAST throttle body and a couple other little changes.

SteveAle

Well-Known Member

Made it back to dyno this time no problems fired right up. After some initial set up we was ready to start making pulls. We made about 5 good pulls messing around with timing and various other settings. I would like to say anyone thinking about the Holley EFI system, I highly suggest it. Easy setup, easy tuning, just plain easy all together.

Final numbers: 662 hp @ 6300 rpm and 600 lbs @ 5400 rpm

Final numbers: 662 hp @ 6300 rpm and 600 lbs @ 5400 rpm

SteveAle

Well-Known Member

Here is a link to the lousy video that I did manage to get. I was so worried about tuning and watching the data I totally forgot to get some good video.

SteveAle

Well-Known Member

Next thing I have done was a big Christmas present to myself haha. I needed some metal work done and I am not the most skilled when it comes to welding and fab so I got some guys to do some work for me. Joe Lutz from Hot Rod Dynamics in Lenoir NC did an awesome job on my car for the next step.

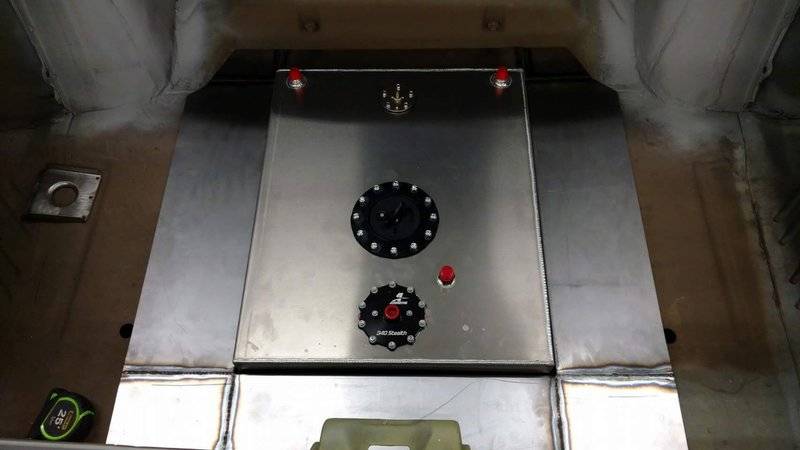

It started out as just wanting some welding on my headers and some trunk fabrication, but I ended up having some welding done on my headers. Had them to build me a crossmember for my transmission that goes up high enough that I can run my 3 inch exhaust with no worries. Cut out my trunk pan and made me a new pan that seal trunk but has a pocket build into it so my fuel cell fits in. Cut out the factory fuel filler hole in body and inserted a nice billet filler cap assembly and made a filler neck pipe to the cell. They fixed the gaps in my wheel tubs from the widening and last but not least. I had the rear end shorted another 3 inches. I wasnt real happy with the wheel tire setup I had, I wanted something much wider under the rear and wasnt fully using the mini tub space I gained.

That got alot done that I was needing. If I dont watch myself soon I will be ready to paint this thing and start with final assembly....

It started out as just wanting some welding on my headers and some trunk fabrication, but I ended up having some welding done on my headers. Had them to build me a crossmember for my transmission that goes up high enough that I can run my 3 inch exhaust with no worries. Cut out my trunk pan and made me a new pan that seal trunk but has a pocket build into it so my fuel cell fits in. Cut out the factory fuel filler hole in body and inserted a nice billet filler cap assembly and made a filler neck pipe to the cell. They fixed the gaps in my wheel tubs from the widening and last but not least. I had the rear end shorted another 3 inches. I wasnt real happy with the wheel tire setup I had, I wanted something much wider under the rear and wasnt fully using the mini tub space I gained.

That got alot done that I was needing. If I dont watch myself soon I will be ready to paint this thing and start with final assembly....

SteveAle

Well-Known Member

Here are some of the pictures from all the work I had done.

-

Similar threads

- Replies

- 110

- Views

- 5K