MR4V

Well-Known Member

Hi All

Just about finsih with the rebuild on the Duster.

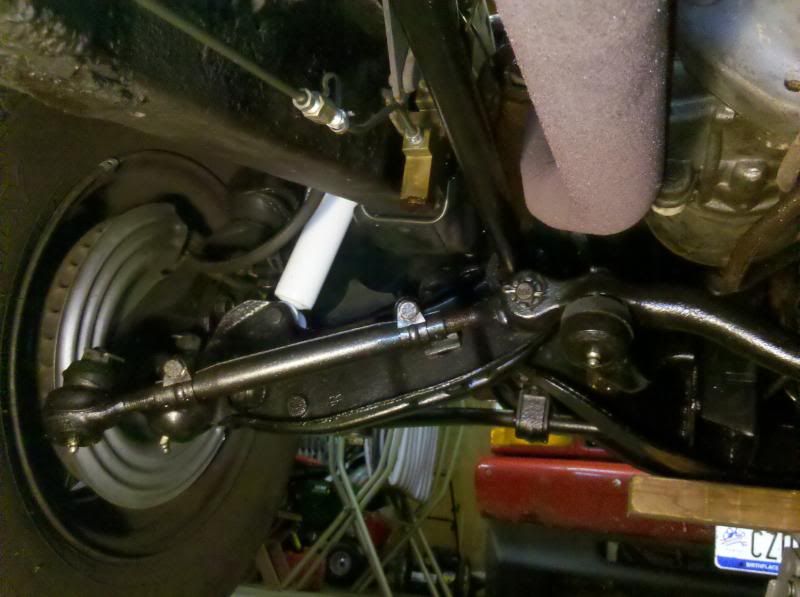

I have noticed that when there is no weight on the fornt end the inner tie rod end on the drivers side hits the torrsion bar & the passages side clears it. When the suspension is under load it hits some times, I'm yet to do a wheel alingment.

Is this normal when a wheel alingment has not been done?

The tie rods were in the car before the rebuild & cleared everything, I have doubled checked everything & the center link is in correctly.

Just about finsih with the rebuild on the Duster.

I have noticed that when there is no weight on the fornt end the inner tie rod end on the drivers side hits the torrsion bar & the passages side clears it. When the suspension is under load it hits some times, I'm yet to do a wheel alingment.

Is this normal when a wheel alingment has not been done?

The tie rods were in the car before the rebuild & cleared everything, I have doubled checked everything & the center link is in correctly.