In this chapter I am going to go through installing the cam bearings in the block... If you don't have the tools or experience to do this at home, then have a qualified machine shop do it for you, but make sure to check the bearings are installed properly by probing the holes with a coat hanger to make sure the oil passages are free flowing as described in this chapter...

This is the next step to continue after part 1 where we tore the block down and cleaned it up... If you missed it, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Cam Bearings:

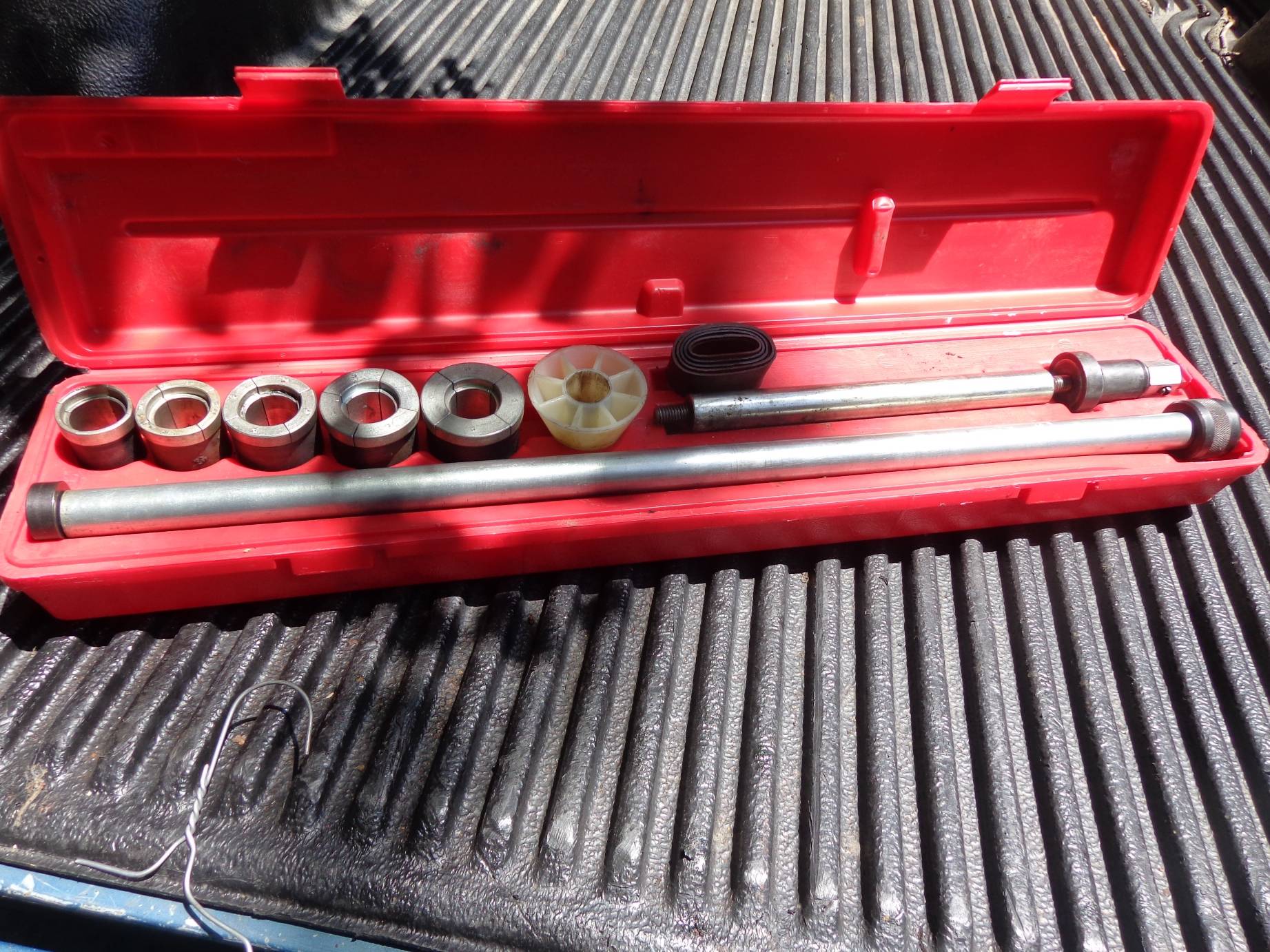

Here's my cam bearing installation tool...

Here is a YouTube video on how to use the cam bearing tool to remove the bearings from the block...

Installing the bearings is similar, but you have to pay attention to the oil holes in each cam bearing... You have to get the oil holes properly lined up so you don't block the oil flow through the engine...

I recommend saving the old bearings and practicing installing them a few times until you get comfortable with the tool and trying to line up the holes.... This way you don't mess up your new ones... If you put them in and out too many times, you can reduce the press fit and increase the chance of spinning that bearing... If you remove a bearing more than 3 times, I would recommend replacing it with a new one so the fit is tight...

Putting the block upside down so you can reach and load the bearing on the tool... Start with the rear cam bearing first and work your way forward as you go...

The rear cam bearing only has one oil hole that feeds from the mains so you should have the oil hole in the rear cam bearing facing upwards at the 12 o'clock position with the block upside down... Now hammer the tool to drive the bearing in while keeping the oil hole in the bearing aligned with the hole in the block...

Try not to install the bearings crooked/cocked, get them as straight as possible and the holes will align properly...

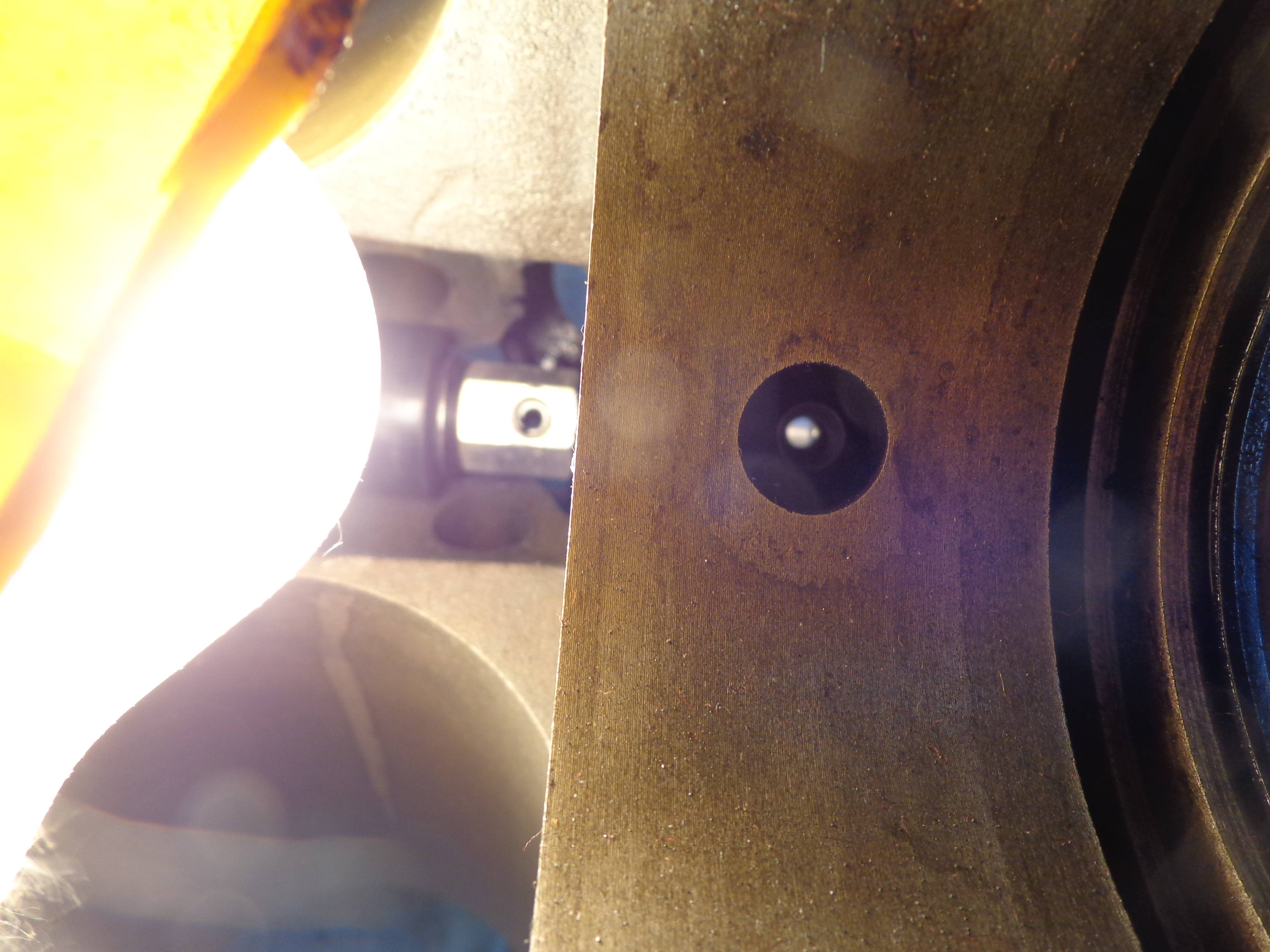

I put a trouble light in the cam area behind the hole and look through the passage in the rear main to see the light coming through...

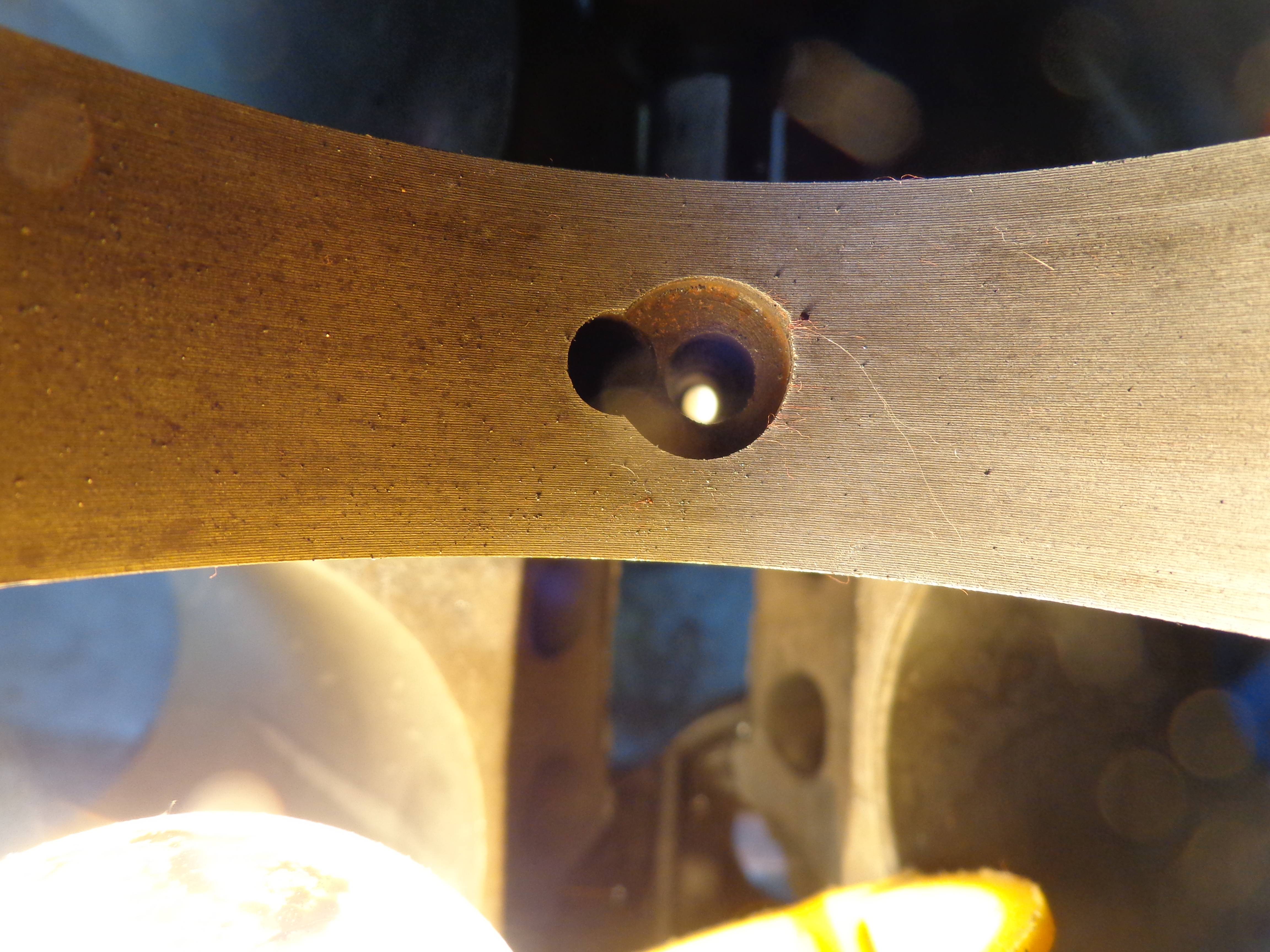

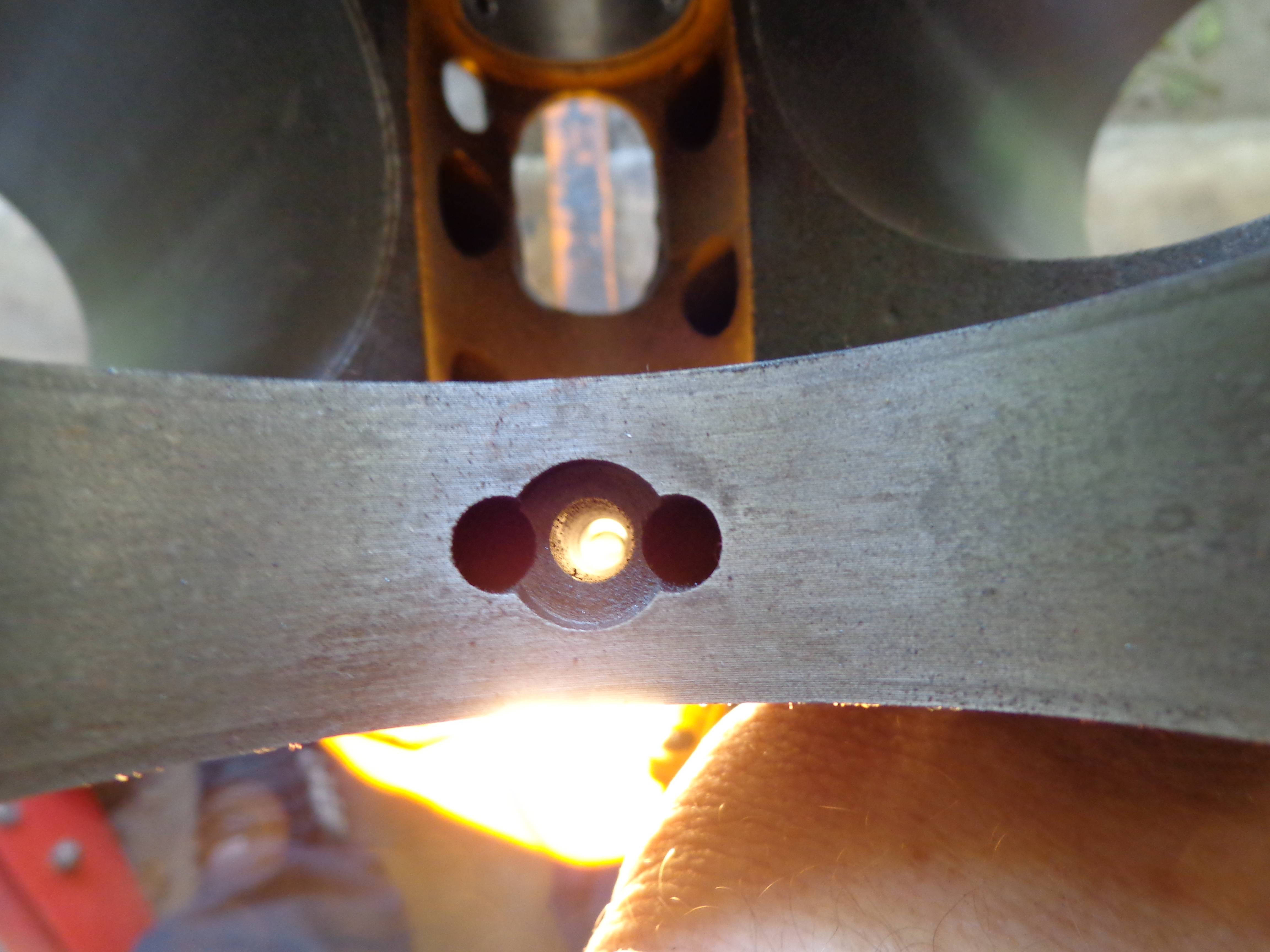

Here's a closer look down the hole and you can see the bearing hole is aligned with the hole in the block...

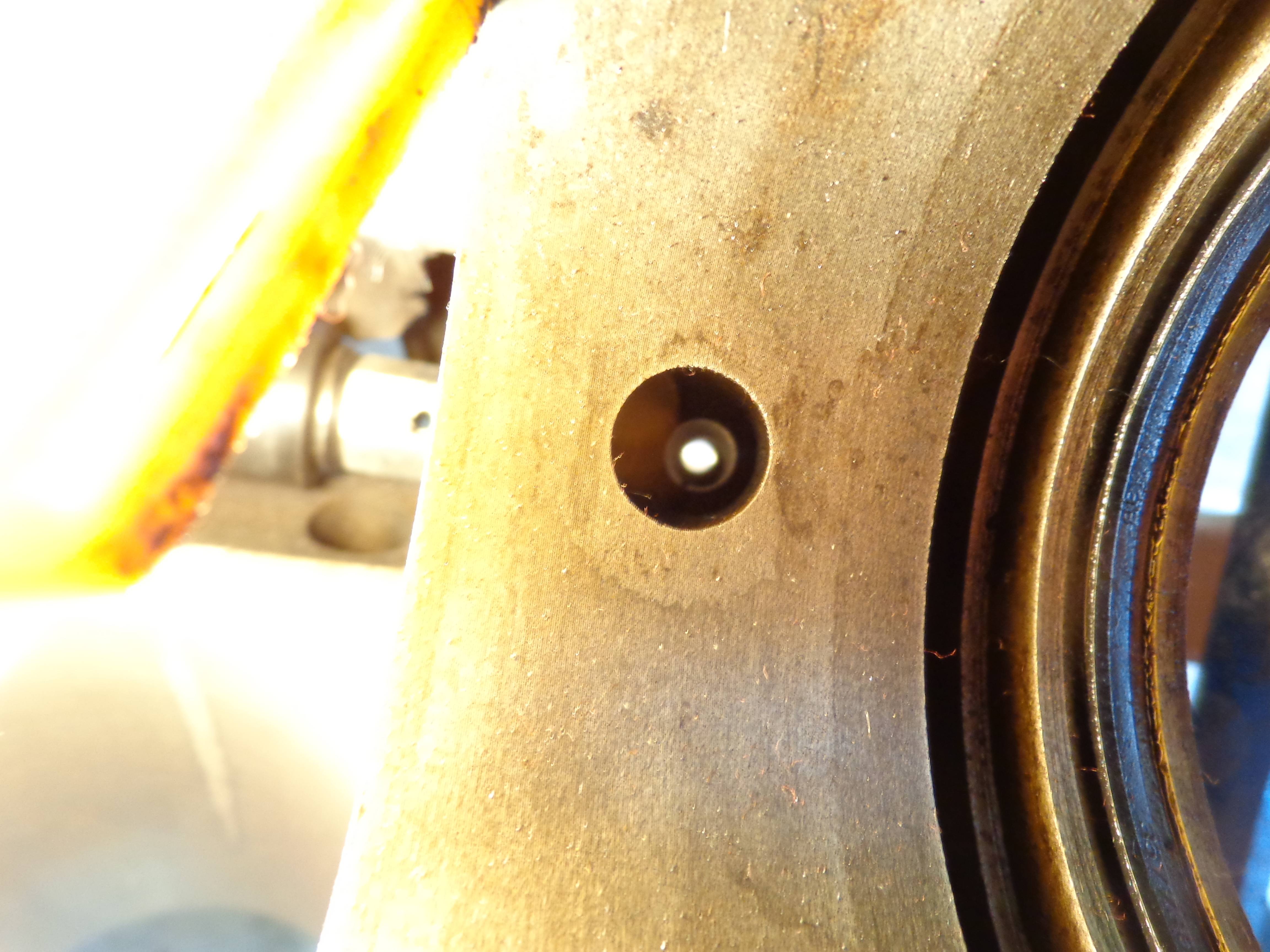

Then I use a straightened wire coat hanger to probe the hole and make sure that it goes all the way through to the cam tunnel to make sure that the hole is not blocked... Push the wire coat hanger in gently so you don't scratch the cam bearings when it comes through..

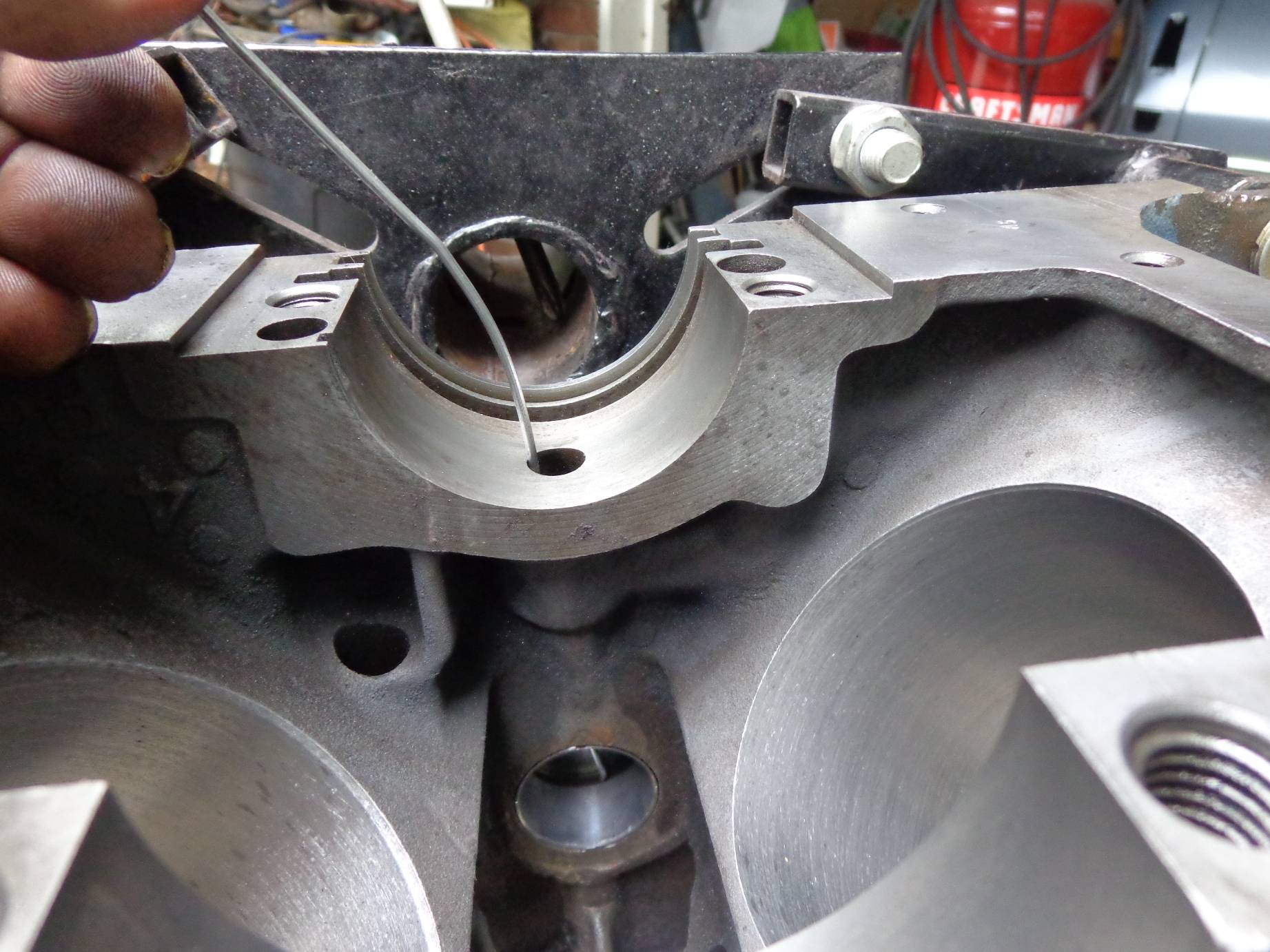

Next we do cam bearing #4 which is the next one in front of the rear... This bearing has 3 holes evenly spaced apart at 120°... You only need two holes, but by making the bearing with three holes, it has less chance of getting installed improperly... Just pay attention to the two holes that you need and ignore the extra one...

This bearing gets oil from the main bearing/crank and then transfers some of it through a passage to oil the passenger side head and rocker arms... You need to make sure that both oil holes for the main bearing feed and head passages are not blocked and the holes in the bearing align with the ones in the block when this bearing is installed... Since the oil holes in the bearing are evenly spaced apart, you just put one hole facing upward with the block upside down and use the oil hole from the mains as your reference...

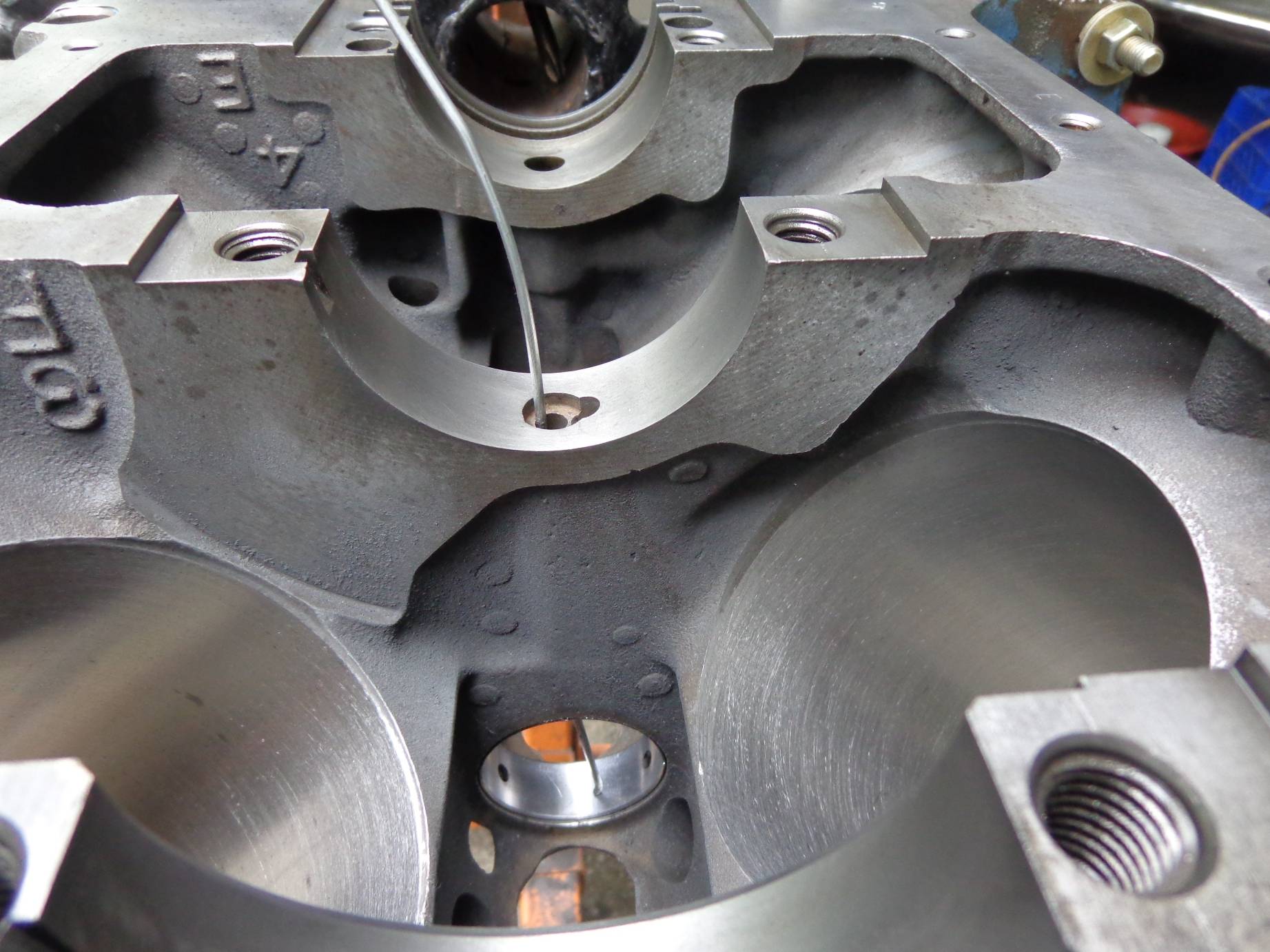

Here I am checking the bottom hole position from the main bearing to the cam bearing hole with a light in the cam tunnel

...

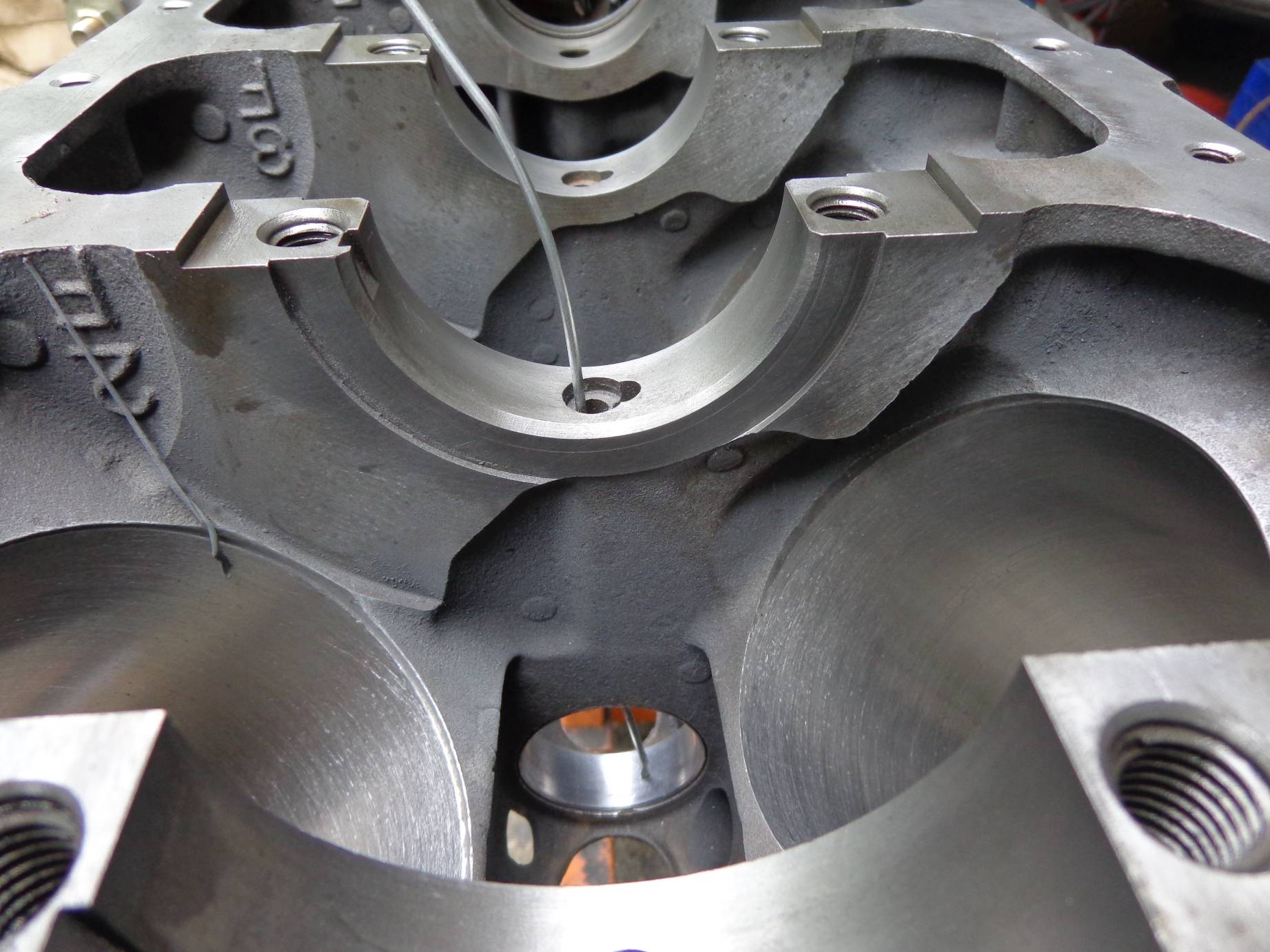

Here's the cam bearing from another angle...

Here's a similar shot with the coat hanger through the holes and you can see it coming through the cam tunnel...

Now check the oil hole for the head with a coat hanger to make sure that the hole for that one and the bearing are aligned and open without any blockage...

Now you do the center/middle cam bearing #3... This one only has one hole for the feed from the main bearings... You just need to install the bearing with the oil hole in the 12 o'clock position with the block upside down...

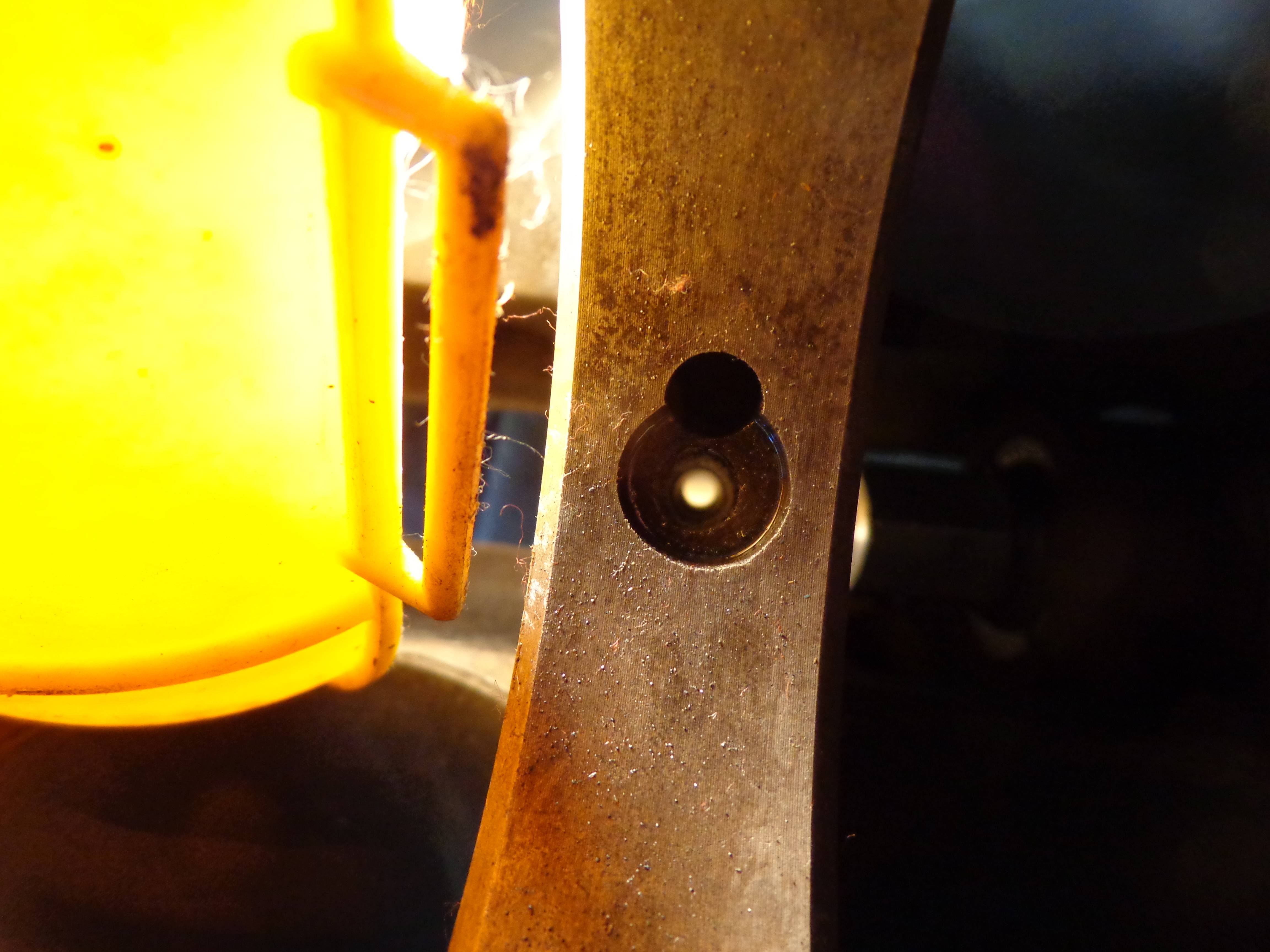

Here is ours with the light showing completely through...

Here's the side shot of the installed bearing...

Here's with the coat hanger poking through to check that the passages are not blocked...

Now we move on to #2 cam bearing which is the one that feeds the driver's side head and rocker arm with oil, so there are two holes you need to pay attention to...

Just like with #4 bearing, the holes are equally spaced apart at 120° so it will make it easier to install... If you use the main bearing hole as your reference to align the holes, the other hole will be in the proper position... The extra hole in the bearing is not used, so you don't have to worry about that...

You just need to install the bearing with an oil hole in the 12 o'clock position with the block upside down and the other will be in place...

Here's looking down from the main bearing with a light under the hole...

Here's a view showing the installed cam bearing...

Here it is with a coat hanger from the main bearing passage...

Here's a couple of shots with a coat hanger through the oil passage for the head...

The front cam bearing only has one hole that goes to the oil passage from the mains/crank... Put the oil hole in the cam bearing in the 12 o'clock position with the block upside down and drive the bearing into the block... Then check the alignment of the hole in the bearing with the hole in the block with a light...

Then probe the hole with a coat hanger....

To make sure that the bearings are all ok, test fit the cam to make sure it goes in all the way and will spin without being too tight...

Congratulations, your cam bearings are in and installed properly!!!

Now you are ready to move onto part 3, block hardware assembly....

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

This is the next step to continue after part 1 where we tore the block down and cleaned it up... If you missed it, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Cam Bearings:

Here's my cam bearing installation tool...

Here is a YouTube video on how to use the cam bearing tool to remove the bearings from the block...

Installing the bearings is similar, but you have to pay attention to the oil holes in each cam bearing... You have to get the oil holes properly lined up so you don't block the oil flow through the engine...

I recommend saving the old bearings and practicing installing them a few times until you get comfortable with the tool and trying to line up the holes.... This way you don't mess up your new ones... If you put them in and out too many times, you can reduce the press fit and increase the chance of spinning that bearing... If you remove a bearing more than 3 times, I would recommend replacing it with a new one so the fit is tight...

Putting the block upside down so you can reach and load the bearing on the tool... Start with the rear cam bearing first and work your way forward as you go...

The rear cam bearing only has one oil hole that feeds from the mains so you should have the oil hole in the rear cam bearing facing upwards at the 12 o'clock position with the block upside down... Now hammer the tool to drive the bearing in while keeping the oil hole in the bearing aligned with the hole in the block...

Try not to install the bearings crooked/cocked, get them as straight as possible and the holes will align properly...

I put a trouble light in the cam area behind the hole and look through the passage in the rear main to see the light coming through...

Here's a closer look down the hole and you can see the bearing hole is aligned with the hole in the block...

Then I use a straightened wire coat hanger to probe the hole and make sure that it goes all the way through to the cam tunnel to make sure that the hole is not blocked... Push the wire coat hanger in gently so you don't scratch the cam bearings when it comes through..

Next we do cam bearing #4 which is the next one in front of the rear... This bearing has 3 holes evenly spaced apart at 120°... You only need two holes, but by making the bearing with three holes, it has less chance of getting installed improperly... Just pay attention to the two holes that you need and ignore the extra one...

This bearing gets oil from the main bearing/crank and then transfers some of it through a passage to oil the passenger side head and rocker arms... You need to make sure that both oil holes for the main bearing feed and head passages are not blocked and the holes in the bearing align with the ones in the block when this bearing is installed... Since the oil holes in the bearing are evenly spaced apart, you just put one hole facing upward with the block upside down and use the oil hole from the mains as your reference...

Here I am checking the bottom hole position from the main bearing to the cam bearing hole with a light in the cam tunnel

...

Here's the cam bearing from another angle...

Here's a similar shot with the coat hanger through the holes and you can see it coming through the cam tunnel...

Now check the oil hole for the head with a coat hanger to make sure that the hole for that one and the bearing are aligned and open without any blockage...

Now you do the center/middle cam bearing #3... This one only has one hole for the feed from the main bearings... You just need to install the bearing with the oil hole in the 12 o'clock position with the block upside down...

Here is ours with the light showing completely through...

Here's the side shot of the installed bearing...

Here's with the coat hanger poking through to check that the passages are not blocked...

Now we move on to #2 cam bearing which is the one that feeds the driver's side head and rocker arm with oil, so there are two holes you need to pay attention to...

Just like with #4 bearing, the holes are equally spaced apart at 120° so it will make it easier to install... If you use the main bearing hole as your reference to align the holes, the other hole will be in the proper position... The extra hole in the bearing is not used, so you don't have to worry about that...

You just need to install the bearing with an oil hole in the 12 o'clock position with the block upside down and the other will be in place...

Here's looking down from the main bearing with a light under the hole...

Here's a view showing the installed cam bearing...

Here it is with a coat hanger from the main bearing passage...

Here's a couple of shots with a coat hanger through the oil passage for the head...

The front cam bearing only has one hole that goes to the oil passage from the mains/crank... Put the oil hole in the cam bearing in the 12 o'clock position with the block upside down and drive the bearing into the block... Then check the alignment of the hole in the bearing with the hole in the block with a light...

Then probe the hole with a coat hanger....

To make sure that the bearings are all ok, test fit the cam to make sure it goes in all the way and will spin without being too tight...

Congratulations, your cam bearings are in and installed properly!!!

Now you are ready to move onto part 3, block hardware assembly....

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs