You going to the Mopar show tomorrow? We are planning on it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Dodge Dart 270 Convertible for the Wife

- Thread starter Jim Kueneman

- Start date

-

Went to the Tucson Mopar Club Show today and @billccm and @Red's '72 Dart where there. Got a few photos of them to put faces to the names...

Asked the wife if I was watching the super bowl tomorrow or working on her Dart..... Someone let me know who wins...

Asked the wife if I was watching the super bowl tomorrow or working on her Dart..... Someone let me know who wins...

Last edited:

I can't believe it is over and I am getting MUCH better at welding and MUCH faster the process. I have not spot welded the lips and lower quarter edges yet because I wanted to blast the inside the trunk welds and wanted the media to fall out the bottom between the lower quarter and trunk extension. Next weekend hit the spot welds and all the metal patches should be FINISHED!

Got the boss working a bit today!

Little help keeping the blocks in the clamps.

This side came out BEAUTIFUL because I thought of something on the, of course, last panel...

Aligned the panels with the trusty Model Railroad steel ruler then tacked it right behind and walked down the panel.... It came out almost perfectly aligned.

Got the boss working a bit today!

Little help keeping the blocks in the clamps.

This side came out BEAUTIFUL because I thought of something on the, of course, last panel...

Aligned the panels with the trusty Model Railroad steel ruler then tacked it right behind and walked down the panel.... It came out almost perfectly aligned.

Perfect

The other side needed this alignment but I just did a bit of dolly and hammer work to make it better.

Getting the hang of the hammer and dolly, this panel is MUCH better....

We have a solid rear quarter section of the old '63! Ready for the next coat of epoxy primer and then start working the filler.

From the Design Room....

Here is where she is going with the Dart. Only difference will be we will add some white stripes to de-accent the torpedo tube launcher front fenders/headlights....

Here is where she is going with the Dart. Only difference will be we will add some white stripes to de-accent the torpedo tube launcher front fenders/headlights....

Ok so a bit of pathfinding today... Talked to Rick at Restorations by Rick Kreuziger and he did not have any idea for an early A-body so I did some measurement and found out that the early hinges don't have bushings and pins on the upper hinge but the oversized lower pins that Rick sells would work there too. Rick sent me 4 oversized lower pins and I started the experiment....

Bead blasted and ready to work on.... little did I know what I was getting into....

Notice the hinges are the same but the pins are driven in from opposite sides so when you put it on the car the pin head is up and can't loosen and fall out.

Rick also sells the correct bit to install the oversized pins. This one has done the Coronet, Duster and not the Dart but that is about all she wrote. Smoked it doing the Dart... stay tuned.

Here is an original pin you can see the wear and the lip.

You don't have to be super accurate but try to keep it as vertical as possible. The other cars I did with a hand drill and it was good enough.

On the lower hole keep the shaft centered in the hole you already drilled the best you can.

Pack with a little grease.

Install the new oversized pin. Remember these are lower pins so I will cut them off with a cutoff wheel when done.

Hi-tech driving aid... 9/16" deep I think.

Bead blasted and ready to work on.... little did I know what I was getting into....

Notice the hinges are the same but the pins are driven in from opposite sides so when you put it on the car the pin head is up and can't loosen and fall out.

Rick also sells the correct bit to install the oversized pins. This one has done the Coronet, Duster and not the Dart but that is about all she wrote. Smoked it doing the Dart... stay tuned.

Here is an original pin you can see the wear and the lip.

You don't have to be super accurate but try to keep it as vertical as possible. The other cars I did with a hand drill and it was good enough.

On the lower hole keep the shaft centered in the hole you already drilled the best you can.

Pack with a little grease.

Install the new oversized pin. Remember these are lower pins so I will cut them off with a cutoff wheel when done.

Hi-tech driving aid... 9/16" deep I think.

Last edited:

Second one done..

Now time for the lowers.... Here is where the wheels started to fall off....

There is a little pressure from the S spring but unlike the '67 and up you can't get the spring off without pulling the pin. Notice the fancy vice I am using.

The early cars have a roller on the S spring as you can see here. The newer have the double roller that is attached to the bracket in my hand.

So here is where it got frustrating. That outer bracket on both sides is made of the most incredibly strong steel I have EVER seen. I had to use the 3 normal bit sizes between the old size and the oversize pin size and ended up burning up every one of them before I got these two hinges done. The reamer bit would not touch it without inching the hole out 1/64" at a time and like I said every 1/64" was a battle and destroyed the bits...... I FINALLY got one done and gave up on the other.... Here is the 3 hands I have to release a bit of tension of the S spring and getting the pin aligned and driven home.

Cut off the long pin.

Now time for the lowers.... Here is where the wheels started to fall off....

There is a little pressure from the S spring but unlike the '67 and up you can't get the spring off without pulling the pin. Notice the fancy vice I am using.

The early cars have a roller on the S spring as you can see here. The newer have the double roller that is attached to the bracket in my hand.

So here is where it got frustrating. That outer bracket on both sides is made of the most incredibly strong steel I have EVER seen. I had to use the 3 normal bit sizes between the old size and the oversize pin size and ended up burning up every one of them before I got these two hinges done. The reamer bit would not touch it without inching the hole out 1/64" at a time and like I said every 1/64" was a battle and destroyed the bits...... I FINALLY got one done and gave up on the other.... Here is the 3 hands I have to release a bit of tension of the S spring and getting the pin aligned and driven home.

Cut off the long pin.

Mounted on the LH door ready for install.

So after the break of installing the LH door I went back to the drilling and finally got it done... 4 drill bits are gone.... The newer hinges were NOTHING like these...

So here is how I do this alone... Slide the door into the opening and get the upper hinge screws started. Align the top of the door with the cowl top and then loosen the bolts in the door to pull it out to have clearance between the door and the cowl so you don't damage either when you open the door.

Also set the rear gap now close. I use paint sticks for gauges.

Now open the door and get the lower hinge started then use sticks to pry the door up, note the upper hinge only the bolt that faces out is tight the other 2 are barely tight so the hinge can't rock. Tighten the bottom and get it level with the quarter panel with a few adjustments. Now loosen the door to hinge bolts to get the right gap at the cowl and align the door with the rocker.

Most of the time the door needs to be twisted to fit flush

Boy that hood is in sorry shape. Gonna take some filler....

This fender is a PIA to align and I gave up for the day. Fresh eyes tomorrow.

So after the break of installing the LH door I went back to the drilling and finally got it done... 4 drill bits are gone.... The newer hinges were NOTHING like these...

So here is how I do this alone... Slide the door into the opening and get the upper hinge screws started. Align the top of the door with the cowl top and then loosen the bolts in the door to pull it out to have clearance between the door and the cowl so you don't damage either when you open the door.

Also set the rear gap now close. I use paint sticks for gauges.

Now open the door and get the lower hinge started then use sticks to pry the door up, note the upper hinge only the bolt that faces out is tight the other 2 are barely tight so the hinge can't rock. Tighten the bottom and get it level with the quarter panel with a few adjustments. Now loosen the door to hinge bolts to get the right gap at the cowl and align the door with the rocker.

Most of the time the door needs to be twisted to fit flush

Boy that hood is in sorry shape. Gonna take some filler....

This fender is a PIA to align and I gave up for the day. Fresh eyes tomorrow.

Will be doing a bit of hammering tomorrow and trying to get the panels aligned better.

Here we go again... storm moving in so it got windy which was nice for the sanding but sucked for the welding...

Time to put a nail in the coffin of these quarter panels!

If you buy one tool for metal work buy spot weld pliers.... worth every penny.....

Make sure the two panel are touching tightly.

I drilled the holes I punched before out more. I had problems of the weld arcing to the side and welding the edge of the outer panel and not getting a good bite on the lower panel. Drill enough to get nice clean metal in the second panel.

Center the welder and strike an arch directly in the center and build a blob only on the inner panel then fill it in.

If you can't fill spot welds in on the first try, neither can I. Make sure you fill these in so any water can't get in behind the paint from the inside. That will cause the paint to fail..

I cheated and cut the rear panel to make the quarter repair and to be able to blast. Time to fix it and get these panels all welded in.

I can't weld these good enough to not have to grind them either...

All done....

Rear panel all done too.

Time to put a nail in the coffin of these quarter panels!

If you buy one tool for metal work buy spot weld pliers.... worth every penny.....

Make sure the two panel are touching tightly.

I drilled the holes I punched before out more. I had problems of the weld arcing to the side and welding the edge of the outer panel and not getting a good bite on the lower panel. Drill enough to get nice clean metal in the second panel.

Center the welder and strike an arch directly in the center and build a blob only on the inner panel then fill it in.

If you can't fill spot welds in on the first try, neither can I. Make sure you fill these in so any water can't get in behind the paint from the inside. That will cause the paint to fail..

I cheated and cut the rear panel to make the quarter repair and to be able to blast. Time to fix it and get these panels all welded in.

I can't weld these good enough to not have to grind them either...

All done....

Rear panel all done too.

Perspective is in the eye of the beholder....

Well look here... Kaelyn came out to help. What a surprise, just wanted to spend time with the old man and work on an old Mopar.... Great kid!

Huge dent here but I shrunk the metal and beat it back close. Use a 1/2" strap as a straight edge to ensure there were no high spots.

DA sanded the rest of the car and wiped it down.... Next weekend it is time to hit it with the real epoxy primer base coating then from there it is time for filler and blocking! We are getting close. Still have the trunk to do but that can wait. I want to see a straight body first!

This fender fits like crap.... To get a gap to the door I had to elongate the hole in the bottom but now there is so much twisting it rolls out behind the wheel.. I am not sure what to do.

Well look here... Kaelyn came out to help. What a surprise, just wanted to spend time with the old man and work on an old Mopar.... Great kid!

Huge dent here but I shrunk the metal and beat it back close. Use a 1/2" strap as a straight edge to ensure there were no high spots.

DA sanded the rest of the car and wiped it down.... Next weekend it is time to hit it with the real epoxy primer base coating then from there it is time for filler and blocking! We are getting close. Still have the trunk to do but that can wait. I want to see a straight body first!

This fender fits like crap.... To get a gap to the door I had to elongate the hole in the bottom but now there is so much twisting it rolls out behind the wheel.. I am not sure what to do.

Did you use chrome paint for the instrument bezel or send it out?

Put the decals on with a set of tweezer and then painted the needles with the same orange I painted my Coronet with....

View attachment 1715418149

All done. You can bend the tang at the base of the needle to set how far to the left it goes on the gas and temperature gauges. I set them not to be so far buried....

View attachment 1715418150

The circuits board was really bad. I flattened out the copper foil and then used my SPI Universal Clear and brushed it on to seal and lock in the foil.

View attachment 1715418151

A have no idea where I bought this but it has been in the garage for years. I used it to create a foam seal so the blinker/oil/dash lights don't bleed across in the center of the gauges..

View attachment 1715418152

Not pretty but it will work...

View attachment 1715418153

Here we go all done.

View attachment 1715418154

I installed the clips and nuts to hold the foil down. In a few days I will remove them and polish the foil where we need connections.

View attachment 1715418155

Bead blasted the dash end caps and painted them with OER turquoise plastic paint.

View attachment 1715418156

The top says on by having the "T" rotate in the slot the bottom has a screw..

View attachment 1715418157 View attachment 1715418158

Vacuum Ornamental in Romulus Mi. Frank is great to work with and does amazing work. Several Dash restoration places use him. Email and he will give you a quote and time estimate which he meets. You can’t get a finish like that with paint.Did you use chrome paint for the instrument bezel or send it out?

Dentist for 2 crowns in the morning then 3 days to "get'er done" on the Dart...... All the intake and exhaust goodies should be at the post office.... photos coming....

TexasDart

Well-Known Member

Did you say you really wanted a red one.

Scamp Rhonda

Well-Known Member

If the rest of the Body and Frame are good and aligned well I would hang that fender as best as possible first. Then I would cut a slice out in front of the rear edge of the fender to get the right gap. Tack it back together and check gap. Finish welding it back together. Go slow. A lot of work but when you're done it shouldn't be noticeable.Perspective is in the eye of the beholder....

View attachment 1715467421

Well look here... Kaelyn came out to help. What a surprise, just wanted to spend time with the old man and work on an old Mopar.... Great kid!

View attachment 1715467422

Huge dent here but I shrunk the metal and beat it back close. Use a 1/2" strap as a straight edge to ensure there were no high spots.

View attachment 1715467423 View attachment 1715467424

DA sanded the rest of the car and wiped it down.... Next weekend it is time to hit it with the real epoxy primer base coating then from there it is time for filler and blocking! We are getting close. Still have the trunk to do but that can wait. I want to see a straight body first!

View attachment 1715467425 View attachment 1715467426

This fender fits like crap.... To get a gap to the door I had to elongate the hole in the bottom but now there is so much twisting it rolls out behind the wheel.. I am not sure what to do.

View attachment 1715467427 View attachment 1715467428 View attachment 1715467429 View attachment 1715467430

Good luck. Steve

Thanks. I really don’t want to do that but I am getting convinced I will have to do it.If the rest of the Body and Frame are good and aligned well I would hang that fender as best as possible first. Then I would cut a slice out in front of the rear edge of the fender to get the right gap. Tack it back together and check gap. Finish welding it back together. Go slow. A lot of work but when you're done it shouldn't be noticeable.

Good luck. Steve

Scamp Rhonda

Well-Known Member

Yeah, I was hopping you were gonna say "I got a better idea". LolThanks. I really don’t want to do that but I am getting convinced I will have to do it.

Took all the chrome and trim to the other local shop in Tucson (used Royal for the Coronet, so so happy with the service results where nice). Much better customer interaction. I had a budget and hoped it would cover us doing _nothing_ in the trim polishing business... I came home with a small bundle. Was a bit more than I was expecting but now I get it how it is priced and understand. I left all the chrome to get re-choromed and the damaged stainless to get repaired and polished for my budget. The bumpers were $600 each and 800 for all the other work.

Dentist today and then Valentines Day so not much done. I ran out of gas so went to town for dinner and gas.... came home with gas and a pizza, too crowed everywhere....

Not bad for a few hand tools and 90 minutes....

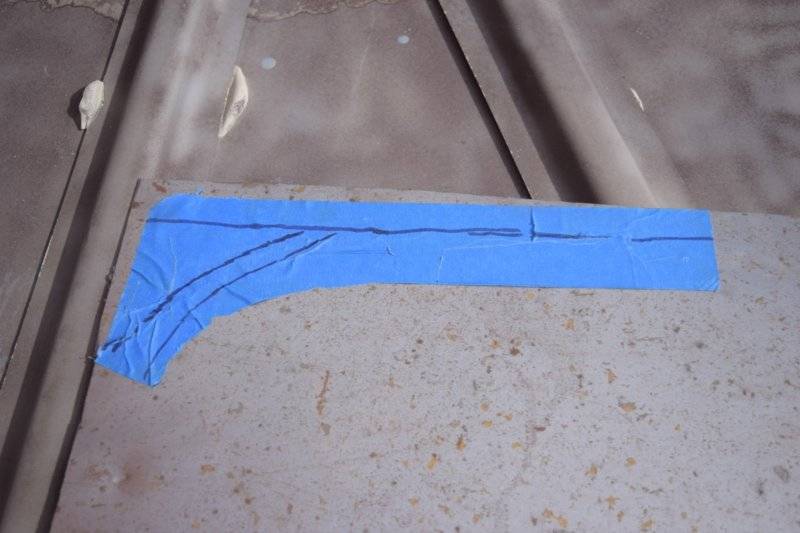

Tape pattern. Go well outside what you think you need because once you shape it the ends will not be were you think.

Transfer to the new metal.

Poor mans break....

Lots of uncontrolled hammering on various items gets it close.

Mark the old metal with the new patch and cut it out with the cutoff wheel.

Weld her in, but make sure you have enough gas to finish......

Not bad for a few hand tools and 90 minutes....

Tape pattern. Go well outside what you think you need because once you shape it the ends will not be were you think.

Transfer to the new metal.

Poor mans break....

Lots of uncontrolled hammering on various items gets it close.

Mark the old metal with the new patch and cut it out with the cutoff wheel.

Weld her in, but make sure you have enough gas to finish......

Last edited:

Well I finally found out why the LH front fender won't line up.... First hint

Second hint....

Third hint and your out.... it is the wrong damn radiator support! It was cut to fit and has the wrong angle where the fender attaches...

So then I started looking closer..... Both shock upper supports had been either cut or cracked and welded too....

See how if I align the fender with the frame edge, like it should be then the fender will line up everywhere.... I searched and search but can't see evidence anything else but the radiator support was replace....

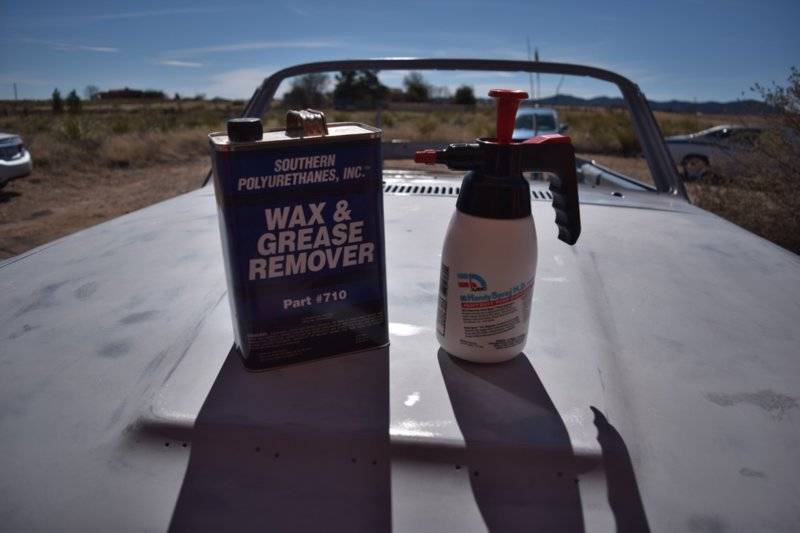

Mystery solved but solution is still rattling around in my head. Over an the SPI forum this sprayer has been in service for 15 years for some people using the 710 wax and grease remover. Rumor is the 700 will eat the seals so this is just for the 710. It works nice but it should for the price. I could barely get 2 weeks out of Ace chemical resistance spray bottles at $9 a clip so this will pay for itself.

See why I was out of gas, hose had a split.... 2 hour round trip to get another was not going to happen so red-neck ingenuity...

Second hint....

Third hint and your out.... it is the wrong damn radiator support! It was cut to fit and has the wrong angle where the fender attaches...

So then I started looking closer..... Both shock upper supports had been either cut or cracked and welded too....

See how if I align the fender with the frame edge, like it should be then the fender will line up everywhere.... I searched and search but can't see evidence anything else but the radiator support was replace....

Mystery solved but solution is still rattling around in my head. Over an the SPI forum this sprayer has been in service for 15 years for some people using the 710 wax and grease remover. Rumor is the 700 will eat the seals so this is just for the 710. It works nice but it should for the price. I could barely get 2 weeks out of Ace chemical resistance spray bottles at $9 a clip so this will pay for itself.

See why I was out of gas, hose had a split.... 2 hour round trip to get another was not going to happen so red-neck ingenuity...

New patch is all welded in and ground down ready for epoxy.

Now look at those body lines!

Now look at those body lines!

-