goldduster318

Overzealous Car Modifier

Hello All,

I did end up ordering the kit from classic auto air with the 26-302 kit with the add-on pulley. The car has a 340 with Edelbrock heads and an Edelbrock Super Victor EFI intake, power steering, and otherwise the stock 1970 318 Non-A/C pulleys.

I did also have to re-seal the timing cover because it was leaking out of the seal and I found apparently that there wasn't a crankshaft oil slinger in place so I had to make a trip over to Mancini Racing to grab one to get it back together right.

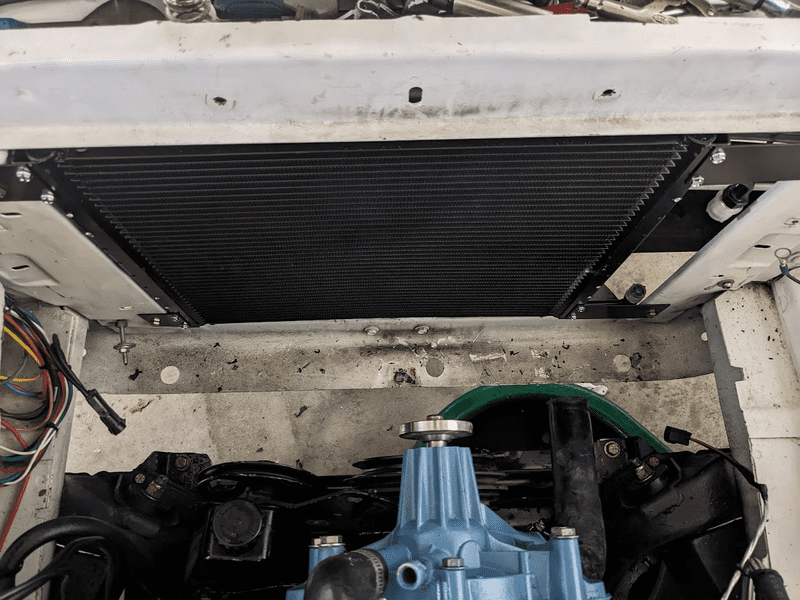

I did some stuff a bit out of order, but I did the compressor mounting and condensor first. I suggest removing the radiator entirely for doing this job.

Crank add-on pulley installed, the other brackets are off due to some paint touch up.

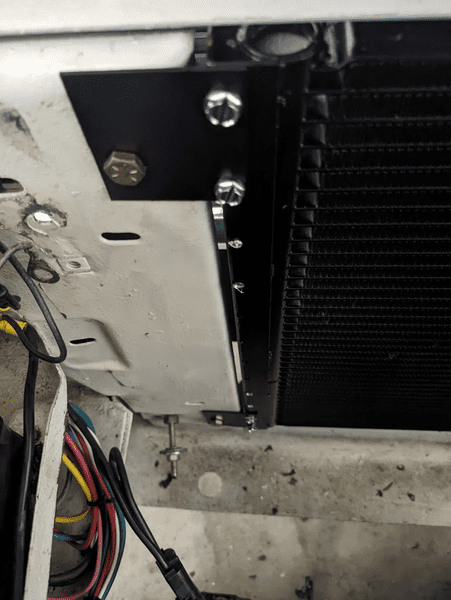

I put the condensor in, the directions are completely wrong, to hit the passenger side stock bolt holes, you have to do them as shown and I had to drill holes for the driver's side and hit them with bolts and nuts. I am using a 26" radiator, so none of these locations are actually touching or used by the radiator, you may have to do something different with a 22"

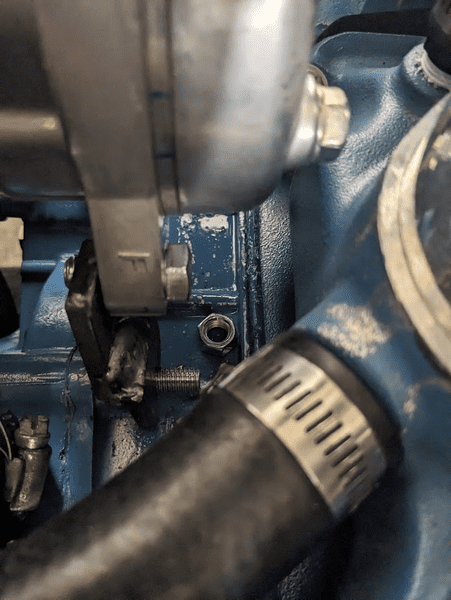

Bracket installed on the engine. The main bracket on the water pump and its spacers fit fine as does the one that goes to the driver's side intake bolt, though it is very close to the bypass hose. The one going to the right cylinder head seems ok at first, but it needed 2 washers in the end. I cannot use the fourth bracket that would go to a spot on the passenger side of the intake because of this intake. If you had a stock one, it would work.

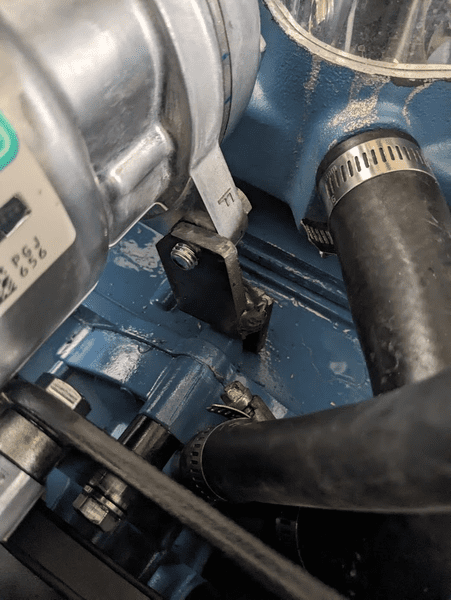

I had to make my own 4th bracket, I replaced the middle water pump bolt with a 4" full thread bolt so it would stick out the back. Then made this bracket out of 1/4" bar stock + 1/8" in the middle that you cant see as a spacer.

Other side is going to work

In my case, the stock belt with the Delco 12SI alternator was too long so I had to go with a 1" shorter belt to not have it hit the ear on the compressor. I had a Gates 7470 and now have a Gates 7460 on there.

Pulleys all installed.

You will have to change the heater hose fitting from 1/2" to 5/8" hose type for this so be sure to do that.

I did end up ordering the kit from classic auto air with the 26-302 kit with the add-on pulley. The car has a 340 with Edelbrock heads and an Edelbrock Super Victor EFI intake, power steering, and otherwise the stock 1970 318 Non-A/C pulleys.

I did also have to re-seal the timing cover because it was leaking out of the seal and I found apparently that there wasn't a crankshaft oil slinger in place so I had to make a trip over to Mancini Racing to grab one to get it back together right.

I did some stuff a bit out of order, but I did the compressor mounting and condensor first. I suggest removing the radiator entirely for doing this job.

Crank add-on pulley installed, the other brackets are off due to some paint touch up.

I put the condensor in, the directions are completely wrong, to hit the passenger side stock bolt holes, you have to do them as shown and I had to drill holes for the driver's side and hit them with bolts and nuts. I am using a 26" radiator, so none of these locations are actually touching or used by the radiator, you may have to do something different with a 22"

Bracket installed on the engine. The main bracket on the water pump and its spacers fit fine as does the one that goes to the driver's side intake bolt, though it is very close to the bypass hose. The one going to the right cylinder head seems ok at first, but it needed 2 washers in the end. I cannot use the fourth bracket that would go to a spot on the passenger side of the intake because of this intake. If you had a stock one, it would work.

I had to make my own 4th bracket, I replaced the middle water pump bolt with a 4" full thread bolt so it would stick out the back. Then made this bracket out of 1/4" bar stock + 1/8" in the middle that you cant see as a spacer.

Other side is going to work

In my case, the stock belt with the Delco 12SI alternator was too long so I had to go with a 1" shorter belt to not have it hit the ear on the compressor. I had a Gates 7470 and now have a Gates 7460 on there.

Pulleys all installed.

You will have to change the heater hose fitting from 1/2" to 5/8" hose type for this so be sure to do that.

!

!