You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coolant flow

- Thread starter Rat Bastid

- Start date

-

Rat Bastid

Dunamis Metron

Man I don't want to jump in here but...

Keep in mind the only time the thermostat flows "high flow" is when it is fully open. Before that it is regulating the flow needed to maintain the low temp, on a cold day it might be bairly open.

I'm going to regret this

That is 100% correct.

Yep, regulates the flow. Which is why I thought it was strange that it was called a thermostat & not a regulator.

A stat is usually a two state device, on or off, open or closed, nothing in between.

A stat is usually a two state device, on or off, open or closed, nothing in between.

But YOU are arguing. I drive my **** ON THE STREET. Just because YOU cant or won’t do something isn’t my problem.

Maybe you ought to drop your coolant temperature, retune your carb and ignition and then report back how shitty it runs. Or maybe how much better it runs. ON THE STREET.

Get the “racing” thing out of your head. That’s your mental road block.

I don’t think I’ve ever said for an EFI (junk you call “modern”) deal to drop the coolant temperature. If I have, it’s because of testing on STREET DRIVEN CARS close to two decades ago.

See, we've had this conversation before. But you seem to have forgotten that I originally set my car up to run colder. I ran it like that for awhile (literally years), and I ran several timing and carburation calibrations during that time. The problem was always the same, the car was a DOG when it was actually cold outside. It would sputter and spit, and lag on the throttle until it was all the way at the very top of the temperature range I was trying to maintain (below 190°). I had no issues maintaining the colder temperatures with my cooling set up at all. And the colder coolant temperatures did not allow me to run more overall timing, I run the same max overall timing now. When it was hot out the car did great.

I went around with timing and carburation, working different timing curves and even entirely different carburetors and distributors, changed out the mechanical flex fan I had been running for my current electric fan set up so I could better control the coolant temperature range. Then I did the logical thing- the car ran great at 190°, and like it was cold and still warming at 180° or below. So I raised the temperature on my electric fans cut in and cut out, because with the electric fan controller I run that takes 30 seconds and costs nothing. Car ran better, still had no overheating issues, and was all around easier to drive. And that was all the time, not just when it was cold out. So I went back into the timing and carburetor and with a little more tuning the car runs great.

Sorry, but your advice is completely rooted in your drag racing background. Drag racers are the only ones that say running your car at 160° is best. And for the drag strip that's fine, for a max hp dyno pull that's fine, heck for a nice weekend afternoon cruise to the park that's fine. At 5am when it's 27° out for the morning commute it's just not what you want. Tried it, worked hard to make it work, discovered it was bad advice, moved on and tuned a better running car.

I did do it your way. And I'm not going to claim my engine is tuned perfectly or even built perfectly for how I use it, I already know it isn't. But I do know that it runs and performs better tuned the way it is now then it ever did tuned to run cold like you say should be best.

Your street car and my circle track car are polar opposites when it comes to cooling system requirements. But for the sake of this discussion let's say that what they have in common is that they both have motors that make 400 horsepower. That is the point I was making in the post. Different applications require different cooling systems including fans.

You said your street car needs to move the most air at idle. The only time my circle track car is idling is when it is in the pit warming up for the race. If it's cool out I have to put cardboard in front of the radiator to even get the needle to come off the peg on the temp gauge. There is no load on the engine at idle so there is very little heat that is produced by the engine and the fan on my racecar even at idle speed is overkill. Is that fan inefficient at idle? Absolutely. But that big (overkill at idle) fan is going to have it's hands full when the car is at speed on the racetrack. Because it is under a heavy load the entire time it's on the race track with no break. Except for an occasional caution flag.

You said your car doesn't even need a fan above 25 mph . The air flow through the grill is sufficient to cool the car. That's because your car's engine has very little load on it to propel itself down the highway. My circle track car has air going through the grill too. It also has an air dam below the radiator to pick up even more air. And that's not anywhere close to enough air to keep the motor cool with out the additional air provided by the fan at 6000+ rpm. It wouldn't make it two laps without a fan and the gauge will be pegged. Due to the continuous high load on the engine.

I'm not saying one fan is better than the other, electric or mechanical. Each has their advantages. I'm saying different applications may require different types of fans.

Put a hitch on your car and hook a 10,000 pound trailer to it. There is a chance your.cooling system requirements might change. Different application, different cooling system requirements.

Right, which is exactly why I said your dirt track example was irrelevant for every other application and pretty much every car discussed on this board. Everything I said is true of my car, and for most cars on this board that see any amount of street time. Idle and low RPM is the challenging time to cool street cars, while anything at speed is typically managed without the fan as long as the radiator and water pump are working properly.

Electric fans work great on these cars. They work great on modern cars, heck an 807 hp Challenger Hellcat runs a single electric fan. But like anything, they have to be set up properly. If you want an electric fan to work properly for your application you have to make sure it's capable of pulling enough CFM, that your electric system can provide it continuously with the large amperage it will need to move that amount of air, and that you're controlling it in a way that can turn the fan on/off reliably when it needs to be. There are a lot of really expensive aftermarket electric fans out there that don't move half the air that's required for most applications with these cars.

I'm just tired of all the guys here that say electric fans are junk and they don't work. They're like anything else. Set them up wrong and they won't work. You can't just slap one on, run a couple of 14 gauge wires to it with a 70 amp alternator and expect success. Pretty much every case I've read on this board where someone says their electric fan set up didn't work was the install. Too small a fan, not enough amperage, undersized wiring, cheesy switching, etc.

Dave999

Well-Known Member

sounds good to me, appropriate equipment to do the job you need it to do.

would be interested to know if your manifold heat crossover was blocked off of indeed deleted from the design you have..

its another area where the basic idea of HEAT BAD dicates many peoples actions without due consideration for what and when the car will be used and whether an effective pump shot is necessary from idle on a cold day . and yes i know fuel has changed and the range of percolation and heat soak issues that can cause.

it's a can of worms that i should not open further..

Dave

would be interested to know if your manifold heat crossover was blocked off of indeed deleted from the design you have..

its another area where the basic idea of HEAT BAD dicates many peoples actions without due consideration for what and when the car will be used and whether an effective pump shot is necessary from idle on a cold day . and yes i know fuel has changed and the range of percolation and heat soak issues that can cause.

it's a can of worms that i should not open further..

Dave

Last edited:

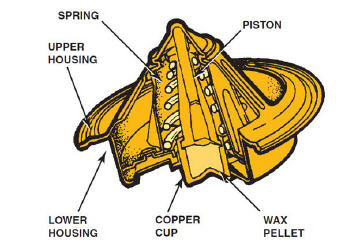

The Robertshaw invention patent applied for in 1957 granted in 1959, not exactly the latest modern technology!

https://image-ppubs.uspto.gov/dirsearch-public/print/downloadPdf/2872117

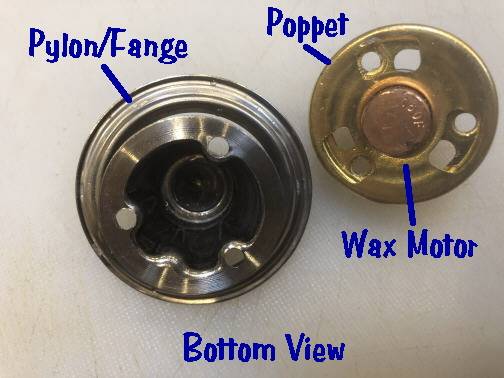

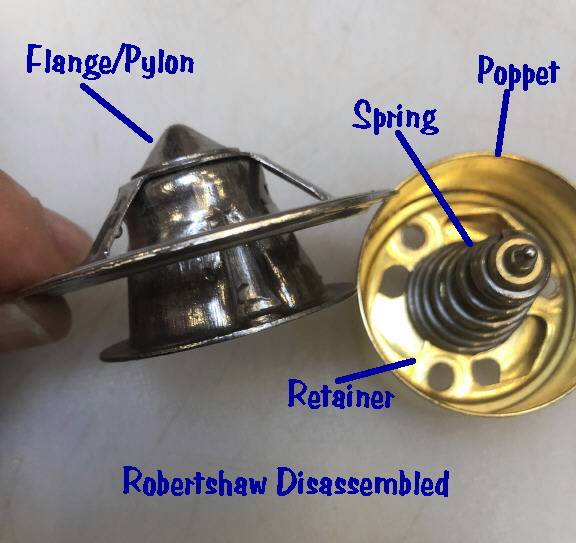

Good explanation, disassembly and pictures (even though the article relates to a 351 Cleveland) of the Robertshaw thermostat from the article:

Robertshaw Ford 351c Cleveland Thermostat

https://image-ppubs.uspto.gov/dirsearch-public/print/downloadPdf/2872117

Good explanation, disassembly and pictures (even though the article relates to a 351 Cleveland) of the Robertshaw thermostat from the article:

Robertshaw Ford 351c Cleveland Thermostat

Last edited:

Rat Bastid

Dunamis Metron

See, we've had this conversation before. But you seem to have forgotten that I originally set my car up to run colder. I ran it like that for awhile (literally years), and I ran several timing and carburation calibrations during that time. The problem was always the same, the car was a DOG when it was actually cold outside. It would sputter and spit, and lag on the throttle until it was all the way at the very top of the temperature range I was trying to maintain (below 190°). I had no issues maintaining the colder temperatures with my cooling set up at all. And the colder coolant temperatures did not allow me to run more overall timing, I run the same max overall timing now. When it was hot out the car did great.

I went around with timing and carburation, working different timing curves and even entirely different carburetors and distributors, changed out the mechanical flex fan I had been running for my current electric fan set up so I could better control the coolant temperature range. Then I did the logical thing- the car ran great at 190°, and like it was cold and still warming at 180° or below. So I raised the temperature on my electric fans cut in and cut out, because with the electric fan controller I run that takes 30 seconds and costs nothing. Car ran better, still had no overheating issues, and was all around easier to drive. And that was all the time, not just when it was cold out. So I went back into the timing and carburetor and with a little more tuning the car runs great.

Sorry, but your advice is completely rooted in your drag racing background. Drag racers are the only ones that say running your car at 160° is best. And for the drag strip that's fine, for a max hp dyno pull that's fine, heck for a nice weekend afternoon cruise to the park that's fine. At 5am when it's 27° out for the morning commute it's just not what you want. Tried it, worked hard to make it work, discovered it was bad advice, moved on and tuned a better running car.

I did do it your way. And I'm not going to claim my engine is tuned perfectly or even built perfectly for how I use it, I already know it isn't. But I do know that it runs and performs better tuned the way it is now then it ever did tuned to run cold like you say should be best.

Right, which is exactly why I said your dirt track example was irrelevant for every other application and pretty much every car discussed on this board. Everything I said is true of my car, and for most cars on this board that see any amount of street time. Idle and low RPM is the challenging time to cool street cars, while anything at speed is typically managed without the fan as long as the radiator and water pump are working properly.

Electric fans work great on these cars. They work great on modern cars, heck an 807 hp Challenger Hellcat runs a single electric fan. But like anything, they have to be set up properly. If you want an electric fan to work properly for your application you have to make sure it's capable of pulling enough CFM, that your electric system can provide it continuously with the large amperage it will need to move that amount of air, and that you're controlling it in a way that can turn the fan on/off reliably when it needs to be. There are a lot of really expensive aftermarket electric fans out there that don't move half the air that's required for most applications with these cars.

I'm just tired of all the guys here that say electric fans are junk and they don't work. They're like anything else. Set them up wrong and they won't work. You can't just slap one on, run a couple of 14 gauge wires to it with a 70 amp alternator and expect success. Pretty much every case I've read on this board where someone says their electric fan set up didn't work was the install. Too small a fan, not enough amperage, undersized wiring, cheesy switching, etc.

Hmmm…I can run mine at sub freezing temperatures with zero issues.

But you can’t do it so it doesn’t work. I get it. Maybe, just maybe you’re missing something on your carb tune.

I will say this. If you weren’t running annular boosters that’s one issue. Plus I have no idea what intake manifold you use.

Cold(er) engine temperatures makes horsepower. Lots of us do it.

And it has nothing to do with “racing”. I can see now that’s your mental hurdle.

Keep giving up power. Don’t learn new things. This is clearly a blind spot for you.

EDIT: I forgot to mention that IF you are down on compression (relative to your cam timing) you can run the engine into detonation because the fuel (or enough of the fuel) isn’t vaporized and you end up with lean spots in the chamber.

I guess I need to do a video (or several) to explain how to drop the coolant temperature and make more power. I can talk 10,000 times faster than I can type.

Last edited:

Rat Bastid

Dunamis Metron

sounds good to me, appropriate equipment to do the job you need it to do.

would be interested to know if your manifold heat crossover was blocked off of indeed deleted from the design you have..

its another area where the basic idea of HEAT BAD dicates many peoples actions without due consideration for what and when the car will be used and whether an effective pump shot is necessary from idle on a cold day . and yes i know fuel has changed and the range of percolation and heat soak issues that can cause.

it's a can of worms that i should not open further..

Dave

Oh FMR. Again, I run my junk year round, in sub freezing weather with a STRIP DOMINATOR and later this year I’ll do it with a tunnel ram.

It can be done. It makes more power.

I can't hardly get my Duster to warm up. I have a clutch fan with no shroud, pulleys are 1 to 1. I'm thinking on removing the fan.... I have an aluminum radiator (Champion) made for a E-body with A/C. 160 T-stat (if my memory serves me correctly, been a few years).

Dave999

Well-Known Member

i'd try a standard themostat before removing the fan.

it really depends on where you live....

it really depends on where you live....

Dave999

Well-Known Member

Oh FMR. Again, I run my junk year round, in sub freezing weather with a STRIP DOMINATOR and later this year I’ll do it with a tunnel ram.

It can be done. It makes more power.

I know it does, but I live in a country where the fuel costs $6.65 or more per US gallon.

and although i occasionally go to the drag strip, more miles are covered in london traffic or on the motorway than down the 1/4 mile.. We have different requirments.

Dave

It sure is. That's why it's so important to have a radiator that can more than handle whatever you're trying to cool. Then the cooling system will work like it's supposed to. The thermostat will actually regulate temperature. If the radiator isn't up to the task, then the thermostat stays open all the time trying to "make up" for what the radiator lacks.That is 100% correct.

FMR? I just KNOW that doesn't mean what I think it does. Fu$k me runnin. Been sayin that since I was a kid. LOLOh FMR. Again, I run my junk year round, in sub freezing weather with a STRIP DOMINATOR and later this year I’ll do it with a tunnel ram.

It can be done. It makes more power.

I might add that if any part of the cooling system isn't up to the task then the thermostat won't be able to regulate temperature.It sure is. That's why it's so important to have a radiator that can more than handle whatever you're trying to cool. Then the cooling system will work like it's supposed to. The thermostat will actually regulate temperature. If the radiator isn't up to the task, then the thermostat stays open all the time trying to "make up" for what the radiator lacks.

Dave999

Well-Known Member

I heartily agree

This has been the gist of everything everyone has said so far, alter the car and if you then swing "out of the operating bounds" of the other components in the system you have a problem.

the solution to the issue will be dependent also on how far away from stock your car/motor/axle ratio/cooling system is and what you use your car for

if its standard or follows their performance or race proven route i think chrylsers advice is prety good, whether thats is service manual or any of the how to "blueprint and build a nice motor" books from the ex race team and employees. I've had no issues when i follow the book and i tend to base any help i try to give on things ive had no issues with. The chrysler guys had a multi national corporation behind them with dyno rooms and warranty claims to worry about, a race program and space stuff, air raid sirens, air conditining units outboard friggin motors train generators, belgian ambulances and spanish cement mixers . the books are old the cars are old but the detail is great and the advice i think still stands, no real reason why it shouldn't they or the bloke they had their lunch with every day designed it...

if your car is built for a specific type of racing you are gonna need to band together with others who do that to find out the good ****... some people here are pretty free and easy with that info, which is great, that seems to be a mopar thing.

we just can't seem to be able agree that this is the case.

Whats good for the goose aint neccessairly good for the gander

Dave

This has been the gist of everything everyone has said so far, alter the car and if you then swing "out of the operating bounds" of the other components in the system you have a problem.

the solution to the issue will be dependent also on how far away from stock your car/motor/axle ratio/cooling system is and what you use your car for

if its standard or follows their performance or race proven route i think chrylsers advice is prety good, whether thats is service manual or any of the how to "blueprint and build a nice motor" books from the ex race team and employees. I've had no issues when i follow the book and i tend to base any help i try to give on things ive had no issues with. The chrysler guys had a multi national corporation behind them with dyno rooms and warranty claims to worry about, a race program and space stuff, air raid sirens, air conditining units outboard friggin motors train generators, belgian ambulances and spanish cement mixers . the books are old the cars are old but the detail is great and the advice i think still stands, no real reason why it shouldn't they or the bloke they had their lunch with every day designed it...

if your car is built for a specific type of racing you are gonna need to band together with others who do that to find out the good ****... some people here are pretty free and easy with that info, which is great, that seems to be a mopar thing.

we just can't seem to be able agree that this is the case.

Whats good for the goose aint neccessairly good for the gander

Dave

Last edited:

Rat Bastid

Dunamis Metron

I heartily agree

This has been the gist of everything everyone has said so far, alter the car and if you then swing "out of the operating bounds" of the other components in the system you have a problem.

the solution to the issue will be dependent also on how far away from stock your car/motor/axle ratio/cooling system is and what you use your car for

if its standard or follows their performance or race proven route i think chrylsers advice is prety good, whether thats is service manual or any of the how to "blueprint and build a nice motor" books from the ex race team and employees. I've had no issues when i follow the book and i tend to base any help i try to give on things ive had no issues with. The chrysler guys had a multi national corporation behind them with dyno rooms and warranty claims to worry about, a race program and space stuff, air raid sirens, air conditining units outboard friggin motors train generators, belgian ambulances and spanish cement mixers . the books are old the cars are old but the detail is great and the advice i think still stands, no real reason why it shouldn't they or the bloke they had their lunch with every day designed it...

if your car is built for a specific type of racing you are gonna need to band together with others who do that to find out the good ****... some people here are pretty free and easy with that info, which is great, that seems to be a mopar thing.

we just can't seem to be able agree that this is the case.

Whats good for the goose aint neccessairly good for the gander

Dave

There is no agreement because people like you think everything that doesn’t fit your narrative is “racing”.

Again, that’s a YOU problem. Once you read something that doesn’t fit your paradigm you assume “racing” and turn your brain off.

It's funny, because for racing, 1/8 and 1/4 mile at least, you can have a really CRAPPY cooling system, since you're not running that long. In fact, run on methanol and throw the radiator in the DITCH. ON THE STREET is where you need the BEST cooling system you can build for a high performance engine. PERIOD.

I'm not going to agree 100% with that. "best cooling system" could be defined in different ways depend on how you score it. But I'll define it as the cooling system that has the potential to remove the most heat.It's funny, because for racing, 1/8 and 1/4 mile at least, you can have a really CRAPPY cooling system, since you're not running that long. In fact, run on methanol and throw the radiator in the DITCH. ON THE STREET is where you need the BEST cooling system you can build for a high performance engine. PERIOD.

A performance car driven on the street is not being "exercised " vigorously for long length of time. Like in your example of a drag car not needing a heavy-duty cooling system. Performance cars driven on the street are given an occasional burst of speed while most of the time just cruising along. The btu's produced under cruising speeds are far less than when the engine is under full load.

Where some street cars struggle is at low speed, stop and go or at Idle. The engine doesn't produce more btu's under these conditions instead the cooling system becomes less efficient. Low coolant flow because of low engine speed and low air flow because now you are relying on the fan only for all your air flow. No additional help from air flowing through the radiator like it gets with the car moving at speed.

In my opinion where cooling systems are really put to the test is in applications where high numbers of btu's are produced. High power engines operated at high load over a long period of time. I think of endurance racing for example. These are very robust cooling systems. Driving a performance car on the street in the same manner they are driven on the racetrack will likely land you in jail and would for many result in an overheated car.

I won't get into vehicles that tow heavy loads on the roads and streets but those too have very robust cooling systems.

<rollseyes>

sounds good to me, appropriate equipment to do the job you need it to do.

would be interested to know if your manifold heat crossover was blocked off of indeed deleted from the design you have..

its another area where the basic idea of HEAT BAD dicates many peoples actions without due consideration for what and when the car will be used and whether an effective pump shot is necessary from idle on a cold day . and yes i know fuel has changed and the range of percolation and heat soak issues that can cause.

it's a can of worms that i should not open further..

Dave

I run an Eddy Air Gap, so, no heat crossover at all and the carb stays colder than on standard intake designs.

Hmmm…I can run mine at sub freezing temperatures with zero issues.

But you can’t do it so it doesn’t work. I get it. Maybe, just maybe you’re missing something on your carb tune.

Right, so if it works on your car everyone should make their car exactly like yours, but if it works on my car that's its a one off and no one should listen. Uh-huh, sure.

I will say this. If you weren’t running annular boosters that’s one issue. Plus I have no idea what intake manifold you use.

I run an Eddy Air Gap with a Holley 750 double pumper. Funny you think that matters now, but are happy to give blanket advice without knowing stuff like that. Application and components matter, which is why your "my way or the highway" take on this can be nothing but wrong. In certain applications you are right, but to lump the entire hobby into that way of tuning is just silly.

Cold(er) engine temperatures makes horsepower. Lots of us do it.

No sir, it's not that simple. Colder intake air temperatures make horsepower. Making horsepower has very little to do with engine coolant temperatures, except that intake manifolds gets hotter with the engine and that raises the intake air temperature. Which is why people run cold air boxes, air gap intakes, etc., and why those things work.

And it has nothing to do with “racing”. I can see now that’s your mental hurdle.

Keep giving up power. Don’t learn new things. This is clearly a blind spot for you.

I'm plenty willing to learn new things, but your take on this isn't "new" and your oversimplification of engine coolant temperature and performance is limiting your understanding. You've lumped engine coolant and air intake temperatures inseparably together, which is a mistake. Yes, you want your air charge to be as cold as possible. And yes, keeping your intake manifold colder helps with that. But air charge temperature depends on more than the intake manifold temperature, and even the intake manifold temperature isn't set solely by the coolant temperature. I'm sure you know that all the different components of the engine aren't always the same temperature. And yeah, if you get off the track and onto the street, extended operation means the intake manifold temperature is driven by a lot of different component temperatures. Your whole engine isn't operating at 160°, I'm sure you understand that. Your combustion temp is in the thousands, colder coolant isn't going to change that much at all. Your under hood engine temperature sure as hell isn't 160°, and changing your coolant temperature from 160° to 190° isn't going to change your under hood temperatures one single bit on a street car out on the road.

EDIT: I forgot to mention that IF you are down on compression (relative to your cam timing) you can run the engine into detonation because the fuel (or enough of the fuel) isn’t vaporized and you end up with lean spots in the chamber.

I guess I need to do a video (or several) to explain how to drop the coolant temperature and make more power. I can talk 10,000 times faster than I can type.

You don't need to do a video. There are literally hundreds and hundreds of books on thermodynamics in general and even just on the thermodynamics of internal combustions engines already, that were written by more intelligent people than both of us, that already explain all of this very clearly. Engine coolant temperature is just a single variable in making more power, and it's no where near the most important one.

If you legitimately think you can improve the tune on my engine to make more power AND maintain drivability, you can PM me and I'll be happy to give you all the details of my build and tuning. But since I've suggested that to you before and heard crickets in response, I won't be holding my breath.

Rat Bastid

Dunamis Metron

I run an Eddy Air Gap, so, no heat crossover at all and the carb stays colder than on standard intake designs.

Right, so if it works on your car everyone should make their car exactly like yours, but if it works on my car that's its a one off and no one should listen. Uh-huh, sure.

I run an Eddy Air Gap with a Holley 750 double pumper. Funny you think that matters now, but are happy to give blanket advice without knowing stuff like that. Application and components matter, which is why your "my way or the highway" take on this can be nothing but wrong. In certain applications you are right, but to lump the entire hobby into that way of tuning is just silly.

No sir, it's not that simple. Colder intake air temperatures make horsepower. Making horsepower has very little to do with engine coolant temperatures, except that intake manifolds gets hotter with the engine and that raises the intake air temperature. Which is why people run cold air boxes, air gap intakes, etc., and why those things work.

I'm plenty willing to learn new things, but your take on this isn't "new" and your oversimplification of engine coolant temperature and performance is limiting your understanding. You've lumped engine coolant and air intake temperatures inseparably together, which is a mistake. Yes, you want your air charge to be as cold as possible. And yes, keeping your intake manifold colder helps with that. But air charge temperature depends on more than the intake manifold temperature, and even the intake manifold temperature isn't set solely by the coolant temperature. I'm sure you know that all the different components of the engine aren't always the same temperature. And yeah, if you get off the track and onto the street, extended operation means the intake manifold temperature is driven by a lot of different component temperatures. Your whole engine isn't operating at 160°, I'm sure you understand that. Your combustion temp is in the thousands, colder coolant isn't going to change that much at all. Your under hood engine temperature sure as hell isn't 160°, and changing your coolant temperature from 160° to 190° isn't going to change your under hood temperatures one single bit on a street car out on the road.

You don't need to do a video. There are literally hundreds and hundreds of books on thermodynamics in general and even just on the thermodynamics of internal combustions engines already, that were written by more intelligent people than both of us, that already explain all of this very clearly. Engine coolant temperature is just a single variable in making more power, and it's no where near the most important one.

If you legitimately think you can improve the tune on my engine to make more power AND maintain drivability, you can PM me and I'll be happy to give you all the details of my build and tuning. But since I've suggested that to you before and heard crickets in response, I won't be holding my breath.

I don’t have time to walk you through a tune up.

I’ll say it again. 180 should be the hottest these thing run. No more. If you want to run more compression drop the coolant temperature.

If you don’t think coolant temperature affects inlet air temperatures you are wrong. They do. That’s why air gap style manifolds work. But look at it. Coolant still goes through it.

A temp gun and some time on a dyno would show you a lot.

If you don’t have a QUALITY annular booster that’s the first place to start. Then emulsion and the main air bleed size.

That should get you started.

BTW, Uncle Tony dropped a video today. Watch that and learn exactly what NOT to do. He’s so far in the weeds on his thinking he won’t find his way out.

EDIT: The video I might make won’t be from text books and ****. It will be real world testing and results. I couldn’t care less what the long haired engineers say. If they say to run coolant temperatures over 180 they are crazy or they are obsessed with their carbon foot print. I’m not. I care about power and driveability. You get more of that with cooler engine temperatures.

Did I mention oil??? That matters too…

Last edited:

Tech Talk #81 – Takin’ It to the Streets

Highlight from the article:

“Use a 160-degree thermostat to help the cooling system maintain control of the engine temperature. I know that most modern automobile engines run at well over 200 degrees, but that’s driven by emission regulations. It’s easier to maintain a reasonable coolant temperature than to regain control after the engine has overheated. The cooling system has a finite capacity to dissipate heat, so keeping the coolant as cold as possible provides a reserve when things start to get hot under the hood”

Read, research, test, make your choice. Done.

Highlight from the article:

“Use a 160-degree thermostat to help the cooling system maintain control of the engine temperature. I know that most modern automobile engines run at well over 200 degrees, but that’s driven by emission regulations. It’s easier to maintain a reasonable coolant temperature than to regain control after the engine has overheated. The cooling system has a finite capacity to dissipate heat, so keeping the coolant as cold as possible provides a reserve when things start to get hot under the hood”

Read, research, test, make your choice. Done.

Tech Talk #78 – The Big Chill: How to Avoid an Engine Meltdown

This is from tech talk #78.

"Why are drag racing engines prone to meltdown? We’ve all watched NASCAR engines run 600 miles at wide-open throttle on a sweltering summer day without problems. At the Bonneville Salt Flats, land speed record racers run flat-out for miles at maximum power. And yet a dedicated drag race car probably wouldn’t last a minute under those conditions.

The answer is in the math. One gallon of gasoline contains roughly 120,000 British Thermal Units (BTU) of heating value, enough energy to raise the temperature of 1,000 pounds of water by 120 degrees. A typical internal combustion engine converts only about 25 percent of the fuel’s energy into useful work (accelerating the car). The rest is turned into waste heat or consumed by mechanical friction. Approximately 30 percent of this waste heat must be dissipated by the engine’s cooling and lubrication systems. So if a drag race engine burns one gallon of gas in the course of staging, burnout, and a quarter-mile run, potentially more than 36,000 BTUs have been dumped into a cooling system with a capacity of only a few gallons of water.

Most drag race cooling systems are utterly inadequate to dissipate such staggering heat. Drag race cars typically use tiny radiators (or sometimes no radiator at all), low-volume electric water pumps, and inefficient fans that simply can’t cope. It’s more accurate to think of these components as “cool down” systems rather than cooling systems, since their chief purpose is to reduce coolant temperature after a run.

A true cooling system would require a massive radiator, a high-volume water pump, and huge fan to balance the input and output of heat. Look at the size of the radiator that’s required to cool a 500-horsepower engine operating continuously in a diesel-powered commercial truck– it’s enormous. Even the cooling systems in passenger cars and light trucks are rarely able to keep up with the heat gain when the engine is run at continuous peak power. That’s why the temperature gauge in my Suburban quickly heads for “H” when I’m towing up a grade."

This is from tech talk #78.

"Why are drag racing engines prone to meltdown? We’ve all watched NASCAR engines run 600 miles at wide-open throttle on a sweltering summer day without problems. At the Bonneville Salt Flats, land speed record racers run flat-out for miles at maximum power. And yet a dedicated drag race car probably wouldn’t last a minute under those conditions.

The answer is in the math. One gallon of gasoline contains roughly 120,000 British Thermal Units (BTU) of heating value, enough energy to raise the temperature of 1,000 pounds of water by 120 degrees. A typical internal combustion engine converts only about 25 percent of the fuel’s energy into useful work (accelerating the car). The rest is turned into waste heat or consumed by mechanical friction. Approximately 30 percent of this waste heat must be dissipated by the engine’s cooling and lubrication systems. So if a drag race engine burns one gallon of gas in the course of staging, burnout, and a quarter-mile run, potentially more than 36,000 BTUs have been dumped into a cooling system with a capacity of only a few gallons of water.

Most drag race cooling systems are utterly inadequate to dissipate such staggering heat. Drag race cars typically use tiny radiators (or sometimes no radiator at all), low-volume electric water pumps, and inefficient fans that simply can’t cope. It’s more accurate to think of these components as “cool down” systems rather than cooling systems, since their chief purpose is to reduce coolant temperature after a run.

A true cooling system would require a massive radiator, a high-volume water pump, and huge fan to balance the input and output of heat. Look at the size of the radiator that’s required to cool a 500-horsepower engine operating continuously in a diesel-powered commercial truck– it’s enormous. Even the cooling systems in passenger cars and light trucks are rarely able to keep up with the heat gain when the engine is run at continuous peak power. That’s why the temperature gauge in my Suburban quickly heads for “H” when I’m towing up a grade."

All this talk about thermostats has brought a question to my mind….

In the 6pak tuning guide they state that in order to get the exact correct tuning on your setup, certain items and parameters MUST be met. One item they state that must be in place is the 195 thermostat, which came stock on 6bbl cars. Seems awful high to me, but my car runs very good with its stock components, and it does have the original 195 thermostat in place. Any opinions on why the need for such a high temp thermostat?

In the 6pak tuning guide they state that in order to get the exact correct tuning on your setup, certain items and parameters MUST be met. One item they state that must be in place is the 195 thermostat, which came stock on 6bbl cars. Seems awful high to me, but my car runs very good with its stock components, and it does have the original 195 thermostat in place. Any opinions on why the need for such a high temp thermostat?

Rat Bastid

Dunamis Metron

All this talk about thermostats has brought a question to my mind….

In the 6pak tuning guide they state that in order to get the exact correct tuning on your setup, certain items and parameters MUST be met. One item they state that must be in place is the 195 thermostat, which came stock on 6bbl cars. Seems awful high to me, but my car runs very good with its stock components, and it does have the original 195 thermostat in place. Any opinions on why the need for such a high temp thermostat?

Yes.

Fuel distribution.

Fuel vaporization.

While they look cool, that induction system has issues. One fix is increasing coolant temperature to help with those.

-