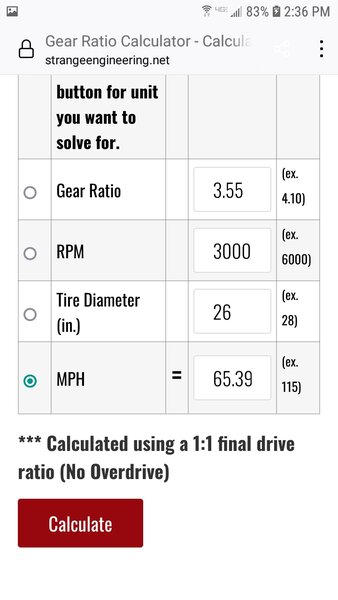

Here are the numbers the Calculators are coming up with:

☆☆☆☆☆

☆☆☆☆☆

honestly now thinking about it the rpm gauge was setup on the 6cy for the slant 6 that was in the car, and i honestly cant remembering changing that to 8 on the gauge. Man would that be a big relief if it was just that on at least the rpm issue. Crossing fingers when i get home lol!Possibly you are feeling the converter Locking Up in second gear, instead of not making it into 3rd yet??

Poor adjustment of the Lokar Cables, not getting the shift points right???

☆☆☆☆☆

Looking like you are taking your mph/rpm readings while it is still in second gear, the way these numbers are coming out.

☆☆☆☆☆

Honestly i forgot that gauge has the 3 settings on it. I will update what i find tonight everyone.Thinking through all of this = Big Brain Teaser....

☆☆☆☆☆

That will put you at 2250 rpm at 50 mph, 67 mph at 3000 rpm. Makes a lot more sense.OK, UPDATE TIME!!!

So first thing, The rpm being to high... found the issue, it was the tach. I never reset it to run on 8cyl mode when I swapped the slant 6 to the 360. Huge sigh of relief. So when I thought my car was idling at 1000 rpm was technically 600 rpm.

Second: attached photo is my exhaust was tapping my transmission cross member. So when I turned through a round a bout, basically a big circle for any of you that's never scene one, the exhaust had adjusted and basically had it tapping the crap out of my transmission mount. Took it off and dented the tube with a 4 pound sledge. Never going to let that happen again lol. I believe that was the terrible sound i heard and fealt this morning on the way to work. I'm stopping there tonight. I will work on looking at cam timing tomorrow and verify if it is truly set at top dead center or if was installed retarded/advanced.. And still maybe shop for a different cam. Maybe get a new one Maybe not.

View attachment 1716113034

Probably another reason why she fealt sluggish. When I'm in drive thinking it was at 900 it was like at 500 is probably another reason it fealt really sluggish also.That will put you at 2250 rpm at 50 mph, 67 mph at 3000 rpm. Makes a lot more sense.

Yes I installed it dot to dot when I put the cam in. So technically me adding that much more advance to it when installing should of gave me more torque down low anyways. Tonight I'm going to go through a whole start over on the Tuning process. Since I thought my park idle was at 1000 when it was in "6cyl mode" on the tach my idle has been wrong this whole time. So I will adjust everything accordingly when I get back from work tonight. That is probably the reason why when I would gun it from idle it fealt so sluggish. With raising the idle to the right point and such it should feel much more snappy. When I started the car after changing the tach setting it was idling at 500 rpm. So hopefully it runs better after some adjustments.Couple of points:

- a tq conv always has some slippage [ only a lock up con vert in LU mode has no slippage ]

- the slight surging you are feeling at slower cruise speeds is because of the cam duration/overlap

- the cam has 5* of advance ground into it. The LSA is 112*. If the cam is correctly ground & everything is machined accurately, then if you installed the cam on the '0' mark of your timing chain set, the ICL is 107. So it is already 5* advanced from the 'straight up' position & I would not advance it any more than an extra 4*.

- a muuuuuuuch better cam for your combo would be the Isky Mega 270. It will idle better [ has 15* less seat timing ] & perform better everywhere else. You can get the current lifters re-faced if they are ok & use them.

When I crank the motor and look at the slot for the disty it doesn't move. It stays in the same orientationintermediate shaft has a gear that rides on the camshaft.. if you could spin it that would be an issue... or do you mean when cranking the motor? cause that would mean your cam isn't turning which would be kinda bad

It's also a brand new melling shaft also.When I crank the motor and look at the slot for the disty it doesn't move. It stays in the same orientation

k.. the gear on the intermediate shaft is usually pinned in, it's rare but they can shear the pin.. if you are lucky nothing else is hurt (it shouldn't have run at all when it sheared) new shaft time... unless you are using a high volume pump i would just use a stock shaft.. but that's me.When I crank the motor and look at the slot for the disty it doesn't move. It stays in the same orientation