Thanks, I was just looking for a ballpark. I'm going N/A with a Victor manifold and 6 pack hood. It'll be tight, but I may get away without a dropped base air cleaner.I haven't had the chance to get my hood on as I'm doing all this solo here in my apartment and needed to always ask someone for help when I need to move it in anad out. But Dave test fitted his with the stock hood and it cleared.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Red Headed Stepchild-75 Swinger LSX Swap

- Thread starter SwingerLSX75

- Start date

-

SwingerLSX75

Well-Known Member

Well I've been climbing in and out of the bay all day today and part of last night. Started cleaning it up and removed the clips and things that applied to the slant that I wont be needing on the LS and did some rust/corrosion control underneath on the rails and tunnel as well. Didn't take a whole lot of pictures during this process so my bad on that, just got really wrapped up in what I was doing and basically only came out of there to eat, use the facilities and get a drink.

This was one of the worst areas for me to have to work on with everything still in there and installed. between the grinder, my dremel and a attachment I have for my drill I got it pretty well smoothed out though except for a few small little spots.

This was after 2 coats of primer, 2 coats of red and 2 coats of clear. All the coverings I had over everything like bags/sheets had been removed at this point but I hadn't yet removed all my blue tape.

This was one of the worst areas for me to have to work on with everything still in there and installed. between the grinder, my dremel and a attachment I have for my drill I got it pretty well smoothed out though except for a few small little spots.

This was after 2 coats of primer, 2 coats of red and 2 coats of clear. All the coverings I had over everything like bags/sheets had been removed at this point but I hadn't yet removed all my blue tape.

Last edited:

True hotrodding

Jeff

Jeff

SwingerLSX75

Well-Known Member

Here are some out of the garage pics from today. I've been heating the garage with my heater to get all this done the last few days since its been between 30-50 the last few days. But even though it was 32, I had to get the car out to do some cleaning up today.

I also happen to do some thinking on the mounts and decided that since that passenger one reaches out so far I wanted to add a gusset/brace in there to help keep it more stable and reinforced incase the front wheels happen to come up and slam down at some point in the future.

I also happened to get bored enough to start thinking about the color scheme of the engine bay, and since I don't want to add too much red in there I wanted to do small accents. So I came up with this. Instead of the entire compressor cover just being polished.

I also happen to do some thinking on the mounts and decided that since that passenger one reaches out so far I wanted to add a gusset/brace in there to help keep it more stable and reinforced incase the front wheels happen to come up and slam down at some point in the future.

I also happened to get bored enough to start thinking about the color scheme of the engine bay, and since I don't want to add too much red in there I wanted to do small accents. So I came up with this. Instead of the entire compressor cover just being polished.

Last edited:

SwingerLSX75

Well-Known Member

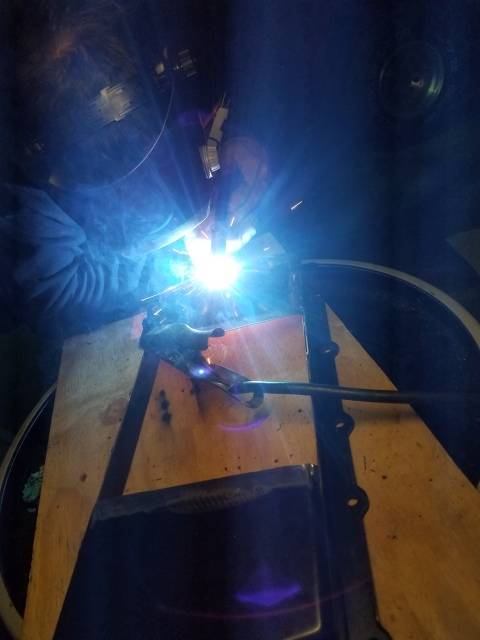

Got the gusset welded up and resprayed and the mount reinstalled.

Had to change the oil on the cherry picker and got it working again and got the engine put back in its hole.

And for those wondering this is my turbo 400, mated to the LS and that is the stock 904 transmission crossmember just flipped backwards, and It literally puts that bolt right under where the turbo 400 support would need to be. so I'm thinking a 3 inch support/spacer bolted to the 904 crossmember and itll be good to go.

Had to change the oil on the cherry picker and got it working again and got the engine put back in its hole.

And for those wondering this is my turbo 400, mated to the LS and that is the stock 904 transmission crossmember just flipped backwards, and It literally puts that bolt right under where the turbo 400 support would need to be. so I'm thinking a 3 inch support/spacer bolted to the 904 crossmember and itll be good to go.

JDMopar

Well-Known Member

Inside the torsion bar cross member, there are little pieces of angle iron welded in an upside down V at each bolt hole for the transmission mount. They keep the bolts from smushing the t bar x member when you crank them down. Make the transmission mount fit the existing holes in the torsion bar cross member instead of vice versa. It's amazing how well that motor fits in the engine bay. I wonder if there are any headers that would fit by the torsion bars with a normally aspirated motor?

SwingerLSX75

Well-Known Member

Inside the torsion bar cross member, there are little pieces of angle iron welded in an upside down V at each bolt hole for the transmission mount. They keep the bolts from smushing the t bar x member when you crank them down. Make the transmission mount fit the existing holes in the torsion bar cross member instead of vice versa. It's amazing how well that motor fits in the engine bay. I wonder if there are any headers that would fit by the torsion bars with a normally aspirated motor?

Ill have to take a look and figure out what you mean with the upside down v and making the trans mount fit.

Right now im kinda thinking of getting a piece of angle iron(or the 1/4 bar plate I have now), cut it to the same length at the gap between those two tabs, and weld it in there, punch two holes in it and then add a transdapt poly mount to the turbo 400, and bolt it to the angle iron(or bar plate) that id weld to the stock trans support bar, and the rest is history.

Last edited:

JDMopar

Well-Known Member

I guess what I wrote was kinda confusing...lol. The bolt holes that go thru the permanently welded in torsion bar cross member are what I was referring to. Each bolt hole has a piece of tubing and other reinforcement welded under it inside the torsion bar cross member where you can't see it. It just keeps the torsion bar cross member from getting crushed in. I found a piece of the torsion bar cross member that I cut out of my Duster to make the 545RFE fit, and you can see the reinforcements for the bolt holes.

SwingerLSX75

Well-Known Member

I plan on keeping the factory torsion bar cross member intact like it is now(minus the small section I cut out to make the turbo 400 fit in, and using the factory 904 trans support bar. All 4 of those holes are still there on my torsion bar cross member, and plan on keeping the stock trans support bar(that bolts to the torsion bar crossmember). Ill take a picture of what I mean tonight when I get home and post it.I guess what I wrote was kinda confusing...lol. The bolt holes that go thru the permanently welded in torsion bar cross member are what I was referring to. Each bolt hole has a piece of tubing and other reinforcement welded under it inside the torsion bar cross member where you can't see it. It just keeps the torsion bar cross member from getting crushed in. I found a piece of the torsion bar cross member that I cut out of my Duster to make the 545RFE fit, and you can see the reinforcements for the bolt holes.View attachment 1715111512 View attachment 1715111513

SwingerLSX75

Well-Known Member

Well I got the oil pan ordered yesterday, it should be here Tuesday, so hopefully I can get it measured, cut and ready to be re-welded before I head to NC for Thanksgiving. Fingers Crossed.

Meanwhile I thought the hood was hitting the intake(causing it to sit high in the back) only to find out I was a dummy and didn't adjust the hood properly. So I readjusted it and low and behold no issues clearing the stock hood with the tall truck intake or the truck style high mount alternator. Forgive the pictures as they were taken with my phone with the car up on the stands and me laying on the ground and reaching up from the ground.

Meanwhile I thought the hood was hitting the intake(causing it to sit high in the back) only to find out I was a dummy and didn't adjust the hood properly. So I readjusted it and low and behold no issues clearing the stock hood with the tall truck intake or the truck style high mount alternator. Forgive the pictures as they were taken with my phone with the car up on the stands and me laying on the ground and reaching up from the ground.

Last edited:

SwingerLSX75

Well-Known Member

Well the new oil pan will be here tomorrow. It is the all steel 7 qt pan from summit. it is in a rear sump orientation which I will then cut, flip and reweld into a center sump so I can clear the center link.

Summit Racing® Economy Oil Pans SUM-G3610B

I was also lucky enough to get a call from my cousin offering me a deal on a cam/spring/pushrod setup, and im thinking of getting at least the springs and pushrods from him. The springs are pac 1219 valve springs and allow for a max of .625 lift cam, and the pushrods are hardened stock length texas speed pushrods. He is selling me the springs and pushrods for $150.

1200 Series - LS Ovate Beehive spring that has increased loads, rates and frequencies for more aggressive cams. This remains a drop in spring for stock parts but will handle increased lifts. - PAC-1219 - PAC Racing Springs

Texas Speed & Performance 5/16" Chromoly Pushrods, 7.35-7.50" Length

Here is the cam he is offereing me with the springs for a total of $350 for all 3 things. which is not a bad deal at all. This cam definitely has the sounds covered, but idk if it packs enough performance for what I want to do.

Howards Cams Hydraulic Roller Camshafts 197715-10

Should hopefully have some oil pan pics tomorrow as well as some cut/test fitted pics. wish me luck.

Summit Racing® Economy Oil Pans SUM-G3610B

I was also lucky enough to get a call from my cousin offering me a deal on a cam/spring/pushrod setup, and im thinking of getting at least the springs and pushrods from him. The springs are pac 1219 valve springs and allow for a max of .625 lift cam, and the pushrods are hardened stock length texas speed pushrods. He is selling me the springs and pushrods for $150.

1200 Series - LS Ovate Beehive spring that has increased loads, rates and frequencies for more aggressive cams. This remains a drop in spring for stock parts but will handle increased lifts. - PAC-1219 - PAC Racing Springs

Texas Speed & Performance 5/16" Chromoly Pushrods, 7.35-7.50" Length

Here is the cam he is offereing me with the springs for a total of $350 for all 3 things. which is not a bad deal at all. This cam definitely has the sounds covered, but idk if it packs enough performance for what I want to do.

Howards Cams Hydraulic Roller Camshafts 197715-10

Should hopefully have some oil pan pics tomorrow as well as some cut/test fitted pics. wish me luck.

I'm no expert on turbo ls cams, but that cam may not be a good match. For the duration the lift seems awfully low and the LSA is pretty tight. I know a lot of guys run the Brian Tooley cams. You can get an idea of the cam specs off his website.

Good to know about the alternator clearance. Would putting a 90 pointing down off the headers and mounting the turbos vertically help with clearance? Not really a turbo guy so don't know if they can be mounted that way. Maybe oiling problems?

Good to know about the alternator clearance. Would putting a 90 pointing down off the headers and mounting the turbos vertically help with clearance? Not really a turbo guy so don't know if they can be mounted that way. Maybe oiling problems?

SwingerLSX75

Well-Known Member

The cam I've been looking at most is this one.I'm no expert on turbo ls cams, but that cam may not be a good match. For the duration the lift seems awfully low and the LSA is pretty tight. I know a lot of guys run the Brian Tooley cams. You can get an idea of the cam specs off his website.

Good to know about the alternator clearance. Would putting a 90 pointing down off the headers and mounting the turbos vertically help with clearance? Not really a turbo guy so don't know if they can be mounted that way. Maybe oiling problems?

Elgin Engine Camshaft E1841P; .595" .595" Hydraulic Roller for Chevy LS1 | eBay

I think it's be a little better for my turbo setup. From what I've read the lower Lsa cams make the most power, but the idle is rougher and run a little slower down lown. The higher the is a the smoother the idle, the faster the lower comes in. I'm talking to ljms about his stage 2 4.8 turbo cam as well.

And I'm currently rolling around a radiator idea about leaning it forward and that would give me the clearance to mount the turbo higher and forward facing in the middle of the bay. Using something like this with a bug 16 inch fan.

3 ROW ALUMINUM RADIATOR FOR 1964 1965 1966 Ford Mustang /Falcon V8 260 289 AT/MT | eBay

I like where ur head is going, placement is huge with this because of running the rest of the hotside pieces. But one thing at a time right now, which is the oil pan tomorrow.

Don't forget you've got a bunch of room behind the inner fenders to run plumbing too. I don't think you need to worry much about the cooling system. LS's have been swapped into everything imaginable and I don't ever recall hearing even a peep about overheating.

SwingerLSX75

Well-Known Member

Once I get the turbo placement down ill decide on the hotside routing.Don't forget you've got a bunch of room behind the inner fenders to run plumbing too. I don't think you need to worry much about the cooling system. LS's have been swapped into everything imaginable and I don't ever recall hearing even a peep about overheating.

On another note, my brother found me a Ford 8.8 out of a town car that was headed for the scrapper at the dealership he works at, so im getting it for free.99, gonna hopefully pick it up this weekend and then figure out the right width to shorten it to and get it prepped for the Dart. This LS swap keeps getting cheaper and closer to finishing, who'd thunk it.

SwingerLSX75

Well-Known Member

Hope everyone had a happy and safe Turkey Day. I had some fun down in NC, saw my family, my kids and of course, picked up more parts and got some work done for the Dsrt.

For starters, i got the new all steel oil pan in the mail Tuesday night. It was a very nice piece and an all steel pan for only $160 I couldn't complain.

Only problem was it was a rear sump pan that interferes with the centerlink. Since i knew that prior to buying it and knew myplan ahead, it stayed nice for about 2.5 seconds.

Essentially i cut the sump out right at the welds and slid it back to the middle because I knew I would need a center sump pan, and the only one I found online was. From sikky, and they want $699 for it. Not really budget friend when that alone would cost more than my motor, turbo, and manifolds. So i went with this. Forgive all the blue tape but i wanted it as tight and secure as I could to check fitment.

Clearance on the stock, unmodified slant 6 kmember.

Depth of the pan, just above the back lip on the kmember.

Place of the sump has it 1" forward of the center link,

and allows for an inch(idk if thats accurate, but its a "my fat thumbs width)of clearance when wheels are turned at full locl on driver side, and even wider on passenger side.

Once everything was verified to fit, i cut the middle portion out and moved it to the rear. And started getting it all ready to weld back up. I also discovered that the camaro oil pickup places it right where I need it for this center sump pan, length and depth (happy coincidence and suprise).

Tada!!! Center sump LS pan that will clear the stock kmember and centerlink.

As if that wasn't enough work to get done, i picked up one of the earlier 6.0 intake/throttle body/fuel rail combos so i can have the factory regulator on the fuel rail and not have to buy another and run it separately.

I also picked up a starter, ignition coils, the camaro pickup tube, and a Ford 8.8 rear end and drive shaft to put under the back of the car. Sooooo lots of work ahead of me.

For starters, i got the new all steel oil pan in the mail Tuesday night. It was a very nice piece and an all steel pan for only $160 I couldn't complain.

Only problem was it was a rear sump pan that interferes with the centerlink. Since i knew that prior to buying it and knew myplan ahead, it stayed nice for about 2.5 seconds.

Essentially i cut the sump out right at the welds and slid it back to the middle because I knew I would need a center sump pan, and the only one I found online was. From sikky, and they want $699 for it. Not really budget friend when that alone would cost more than my motor, turbo, and manifolds. So i went with this. Forgive all the blue tape but i wanted it as tight and secure as I could to check fitment.

Clearance on the stock, unmodified slant 6 kmember.

Depth of the pan, just above the back lip on the kmember.

Place of the sump has it 1" forward of the center link,

and allows for an inch(idk if thats accurate, but its a "my fat thumbs width)of clearance when wheels are turned at full locl on driver side, and even wider on passenger side.

Once everything was verified to fit, i cut the middle portion out and moved it to the rear. And started getting it all ready to weld back up. I also discovered that the camaro oil pickup places it right where I need it for this center sump pan, length and depth (happy coincidence and suprise).

Tada!!! Center sump LS pan that will clear the stock kmember and centerlink.

As if that wasn't enough work to get done, i picked up one of the earlier 6.0 intake/throttle body/fuel rail combos so i can have the factory regulator on the fuel rail and not have to buy another and run it separately.

I also picked up a starter, ignition coils, the camaro pickup tube, and a Ford 8.8 rear end and drive shaft to put under the back of the car. Sooooo lots of work ahead of me.

Last edited:

SwingerLSX75

Well-Known Member

Not a lot new here lately. Ill be in Tucson for work till the 15th. But I did order the oil pan gasket, -10 bulkhead fitting, and some new stepper bits to make the install of the pan a breeze when I get back. I also got the PAC1219 valve springs and Texas speed hardened pushrods in the stock length over Thanksgiving break as well.

I also found a builder kit from mandrelbends.com for $112 that should help making the hotside parts a breeze. I have to measure first so I can decide on the 4.5" radius or the 6" radius. But that part will come after I get this new radiator in place and see if my idea for it works out to give more clearance.

Mandrel Builder Kits

I also found a builder kit from mandrelbends.com for $112 that should help making the hotside parts a breeze. I have to measure first so I can decide on the 4.5" radius or the 6" radius. But that part will come after I get this new radiator in place and see if my idea for it works out to give more clearance.

Mandrel Builder Kits

Last edited:

superchargeddrt

Well-Known Member

Wow looks familiar, this just happened last Friday. My car is painted with BC/CC but I redid the engine compartment with single stage acrylic enamel. Really enjoy your thread, I will be watchingHere are some out of the garage pics from today. I've been heating the garage with my heater to get all this done the last few days since its been between 30-50 the last few days. But even though it was 32, I had to get the car out to do some cleaning up today.

View attachment 1715109879

View attachment 1715109880

I also happen to do some thinking on the mounts and decided that since that passenger one reaches out so far I wanted to add a gusset/brace in there to help keep it more stable and reinforced incase the front wheels happen to come up and slam down at some point in the future.

View attachment 1715109881

View attachment 1715109896

View attachment 1715109897

I also happened to get bored enough to start thinking about the color scheme of the engine bay, and since I don't want to add too much red in there I wanted to do small accents. So I came up with this. Instead of the entire compressor cover just being polished.

View attachment 1715109898

SwingerLSX75

Well-Known Member

Nice work. I used old bed sheets to cover mine, but they worked. Amazing what a little paint can do in the engine bay.Wow looks familiar, this just happened last Friday. My car is painted with BC/CC but I redid the engine compartment with single stage acrylic enamel. Really enjoy your thread, I will be watchingView attachment 1715116896 View attachment 1715116897 View attachment 1715116899 View attachment 1715116900 View attachment 1715116901

I also got my turbo 400 trans mount ordered today too.

superchargeddrt

Well-Known Member

Nice work on your part as well, really enjoying your thread. Guess it's not for everyone but I certainly respect your decision and the innovation/ fabrication. Keep up the good work, I'll be watching.Nice work. I used old bed sheets to cover mine, but they worked. Amazing what a little paint can do in the engine bay.

I also got my turbo 400 trans mount ordered today too.

SwingerLSX75

Well-Known Member

Hoping to have it done and running by spring or summer. A little dull period because of work/holidays, but I have some pieces coming in the mail to finish the oil pan install and plumbing for the oil return. but the oil pan will be mounted by Christmas. after that the next big thing is getting the radiator in place and then starting hotside fab, and getting the rear end under it.Nice work on your part as well, really enjoying your thread. Guess it's not for everyone but I certainly respect your decision and the innovation/ fabrication. Keep up the good work, I'll be watching.

813Demon340

Well-Known Member

Great progress, keep it up!

SwingerLSX75

Well-Known Member

I think I just found a new set of rears(same style and make, just a 15x10 with the right backspace I think to fit the new 8.8 rear end). Hoping to have the rear end under it, and the oil pan on by new years.

SwingerLSX75

Well-Known Member

New goodies. Oil pan gasket, new tapered drill bits, th 400 trans mount, and -10 an oil pan bulkhead fitting.

SwingerLSX75

Well-Known Member

More goodies. Pac 1219 springs, new titanium keepers, Texas speed hardened pushrods(stock length), new valve stems seals for both the exhaust and intake side.

Also got the bulkhead fitting into the oil pan.

Also got the bulkhead fitting into the oil pan.

Last edited:

-