swing69

fightin' socialism

Any updates Dave??/ picts????

Any updates Dave??/ picts????

Picked up a set of poly-loc mounts to help keep the motor in the correct location.

My mounts are kinda new, 4-5 years old, but those huge thick rubber isolators start to sag sooner or later.

Picked up a set of poly-loc mounts to help keep the motor in the correct location.

My mounts are kinda new, 4-5 years old, but those huge thick rubber isolators start to sag sooner or later.

ok -

The poly-loc mounts wont work

( the factory rubber isolators are 1.5" thick ( same as the poly's ) but the rubber compresses about 1/4" with the engine on them)

The extra 1/4" is too high up fr anything to work ( I have to swap centerlinks and cut the fan shroud now to make it work. Before I had them raised with shims to clear the /6 centerlink.

****Could you shorten the bracket....I know it's on an angle, but 1/4" wouldn't take much to make up....??????

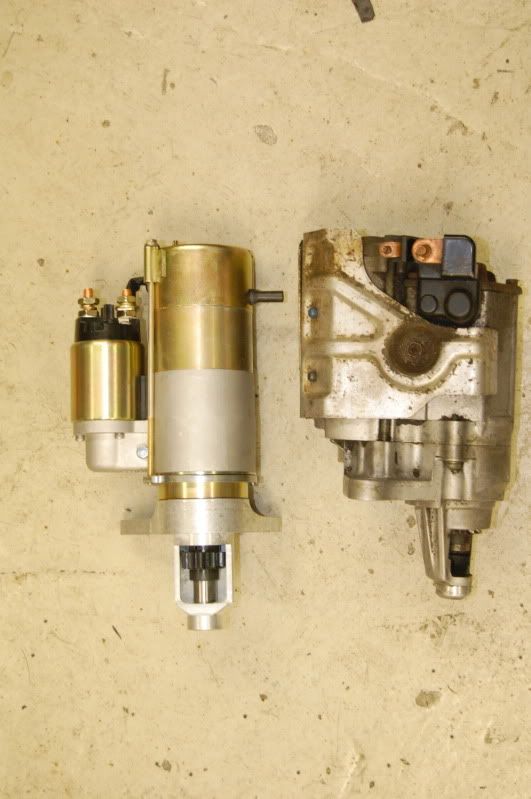

There is no stock starter that works for these headers

One company makes one - and it's clockable 360 degrees... pretty cool, but i found out that it hits the block and will not go in straight.

*****I've heard of others using the R/MC with no issues...?????

It hits here:

*****GRINDER TIME

Got the X member cut, but i still gotta find thick enough sheetmetal to put back on its place.

*****Nice Work...!!!!!!

These ****'s better make some power!!

*****Bet they are your best bet.....looking forward to your results...!!!!! :toothy7:

when you dyno tuning?

Dave, I'm confused. (that doesn't say much)

If the polylocs have the engine sitting 1/4 taller, shouldn't that help with the centerlink clearance with the pan? Or are you saying the higher position makes the header hit somewhere?

The starter fitment is disturbing. TTI says a stock starter will fit (I believe). You are saying the T-bars won't go into the sockets? is that because you can't "thread the needle" through the pipes?

I'm going to run coil overs on the 65, so I think the poly loc wont' be a problem for us.

If you need some metal, Ive got some pieces at the shop that you can use. If you need it welded up, I can do that for you next week. Let me know, give me a call on my cell.

Also: whatever parts you dont' use (polylocs or spitfires) let me know, OK? Mike

Dave. Look into changing you tranny tail shaft angle. You can gain some clearance here. That's what I did but I had the tremec. Try some washers/shims under the tranny mount. Just a thought for ya.