Thought is they may not stay with the car. Looking for a drive shaft loop and sub-frame connectors that bolt in and unbolt just as fast. Also, I don't have a welder.I reckon if you had them already or someone gave them to you for nothing you could drill holes and get into there and bolt them in maybe. But why someone would spend over $150 for basically A straight piece of metal that you usually end up having the weld in anyways is far beyond my comprehension. Me personally I just went and bought a 10 ft piece of Steel for thirty bucks and had them cut it into two 4ft pieces and a 2-foot piece left over. Worked like a charm.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2019 summer race.... Jadaharabi vs 318willrun

- Thread starter 318willrun

- Start date

-

j par

Well-hung Member

And I don't want to hear this crapola of have someone's expecting to buy these things and have them jump out of the box and up and underneath their car. And actually have them fit absolutely perfectly the second they sit up there? LOL bahahaha!

what will really end up having it happening is they'll still have to Jack the car up on 4 jack stands about as high as they can and try and lift that thing up there and get the fit while drilling holes through one side to the other with no room for the drill LOL and have a big huge wrestling match. and then end up not really being in there as tight as I thought it was and taking it down to the muffler shop and having them weld it in anyways.

what will really end up having it happening is they'll still have to Jack the car up on 4 jack stands about as high as they can and try and lift that thing up there and get the fit while drilling holes through one side to the other with no room for the drill LOL and have a big huge wrestling match. and then end up not really being in there as tight as I thought it was and taking it down to the muffler shop and having them weld it in anyways.

Bahahahaha!!!!!!!!!!

So you've tried the bolt-ins ?????? Sorry, i wasn't aware...And I don't want to hear this crapola of have someone's expecting to buy these things and have them jump out of the box and up and underneath their car. And actually have them fit absolutely perfectly the second they sit up there? LOL bahahaha!

what will really end up having it happening is they'll still have to Jack the car up on 4 jack stands about as high as they can and try and lift that thing up there and get the fit while drilling holes through one side to the other with no room for the drill LOL and have a big huge wrestling match. and then end up not really being in there as tight as I thought it was and taking it down to the muffler shop and having them weld it in anyways.

j par

Well-hung Member

Okay there Clint, slap leather! Lol..

j par

Well-hung Member

Again you've got to be kidding me! LOL I took one look at those things and said you got to be kidding me I'm not paying over $200 for a straight piece of Steel! LOLSo you've tried the bolt-ins ?????? Sorry, i wasn't aware...

j par

Well-hung Member

of course after giving you a hard time I will go out to my garage take pictures of mine and measurements and everything else and save you one s*** ton of money. And you'll have better than bolt-in?

I'm not sure I want permanent sub frame connectors. weighing out options is all. I fully understand weld -ins are better. Just looking at every option here. Crackedback has a ton of experience in this sort of thing.of course after giving you a hard time I will go out to my garage take pictures of mine and measurements and everything else and save you one s*** ton of money. And you'll have better than bolt-in?

you should cut them and sell them here on FABOof course after giving you a hard time I will go out to my garage take pictures of mine and measurements and everything else and save you one s*** ton of money. And you'll have better than bolt-in?

j par

Well-hung Member

I'm sure Crackedback knows his stuff. Please don't attempt to get me into an arguing match with somebody who's not here.I'm not sure I want permanent sub frame connectors. weighing out options is all. I fully understand weld -ins are better. Just looking at every option here. Crackedback has a ton of experience in this sort of thing.

If your weld in frame connectors become a problem at some time Sawzall and grinder.

j par

Well-hung Member

I think the overall length with something simple like four feet. Let me go put my slippers on and take some pictures.you should cut them and sell them here on FABO

LOL... I don't attempt to get anyone in an argument. Ha - I copied him and J par shows up giggling at me like a 3rd grade girl....I'm sure Crackedback knows his stuff. Please don't attempt to get me into an arguing match with somebody who's not here.

If your weld in frame connectors become a problem at some time Sawzall and grinder.

I'm just attempting to win a race

P.S.- you don't need any help with that (arguments) anyways.....

Last edited:

j par

Well-hung Member

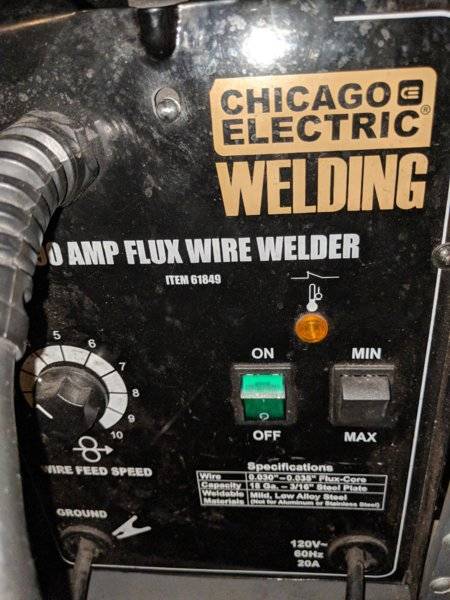

Well you know I've done a thread about everything I've done on this car with pictures I'm sure it was something like homemade frame connectors in the suspension part of the form. But anyways I think I get on about for that $220 for those frame connectors you could buy a welder a hood a grinder with cutting blades steel and have money left over for other stuff too just doing this job.

I think I used one and a half by two and a half outer diameter. I simply filleted open the rear frame enabling me to slide the frame connector inside the frame in the rear. And the front I cut a what looks like 3 in section back cut to give more welding room. I even put a couple Stitch welds on the rear floorboard which it just pressed up against pretty tight. The overall length was just a 4-foot piece.

You can see in the third picture the underside of the rear. The frame connector tube slides in and you can weld up these line up holes. I welded one and left the other alone. I wanted to watch them to see if they would break or Flex. They seem to have done neither.

You can see in the third picture the underside of the rear. The frame connector tube slides in and you can weld up these line up holes. I welded one and left the other alone. I wanted to watch them to see if they would break or Flex. They seem to have done neither.

And don't forget to buy your new welder grinder cutter and helmet foot with the money you save..

now if someone doesn't know how to weld they can take that cutter and cut that last two feet of that 10 footer up into pieces and start welding and watching videos.

I think I used one and a half by two and a half outer diameter. I simply filleted open the rear frame enabling me to slide the frame connector inside the frame in the rear. And the front I cut a what looks like 3 in section back cut to give more welding room. I even put a couple Stitch welds on the rear floorboard which it just pressed up against pretty tight. The overall length was just a 4-foot piece.

And don't forget to buy your new welder grinder cutter and helmet foot with the money you save..

now if someone doesn't know how to weld they can take that cutter and cut that last two feet of that 10 footer up into pieces and start welding and watching videos.

Thanks for the pix & post. Building my own is another option I have on the table as well.Well you know I've done a thread about everything I've done on this car with pictures I'm sure it was something like homemade frame connectors in the suspension part of the form. But anyways I think I get on about for that $220 for those frame connectors you could buy a welder a hood a grinder with cutting blades steel and have money left over for other stuff too just doing this job.

I think I used one and a half by two and a half outer diameter. I simply filleted open the rear frame enabling me to slide the frame connector inside the frame in the rear. And the front I cut a what looks like 3 in section back cut to give more welding room. I even put a couple Stitch welds on the rear floorboard which it just pressed up against pretty tight. The overall length was just a 4-foot piece.View attachment 1715265861 View attachment 1715265862 View attachment 1715265868You can see in the third picture the underside of the rear. The frame connector tube slides in and you can weld up these line up holes. I welded one and left the other alone. I wanted to watch them to see if they would break or Flex. They seem to have done neither.

And don't forget to buy your new welder grinder cutter and helmet foot with the money you save..

View attachment 1715265873 View attachment 1715265874 View attachment 1715265875

now if someone doesn't know how to weld they can take that cutter and cut that last two feet of that 10 footer up into pieces and start welding and watching videos.

I may just leave the car alone too, not like I'm planning on body twisting 1.40's 60 ft times … LOL

j par

Well-hung Member

Not much to make. If you want to just cut it off about 3 in shorter than 4ft. You don't have to filet the end of the piece. You can just but it in up front. Then it's just the three straight cuts to open up the rear frame.Thanks for the pix & post. Building my own is another option I have on the table as well.

I may just leave the car alone too, not like I'm planning on body twisting 1.40's 60 ft times … LOL

This is exactly what I'd do... and what I had in mind if I weldNot much to make. If you want to just cut it off about 3 in shorter than 4ft. You don't have to filet the end of the piece. You can just but it in up front. Then it's just the three straight cuts to open up the rear frame.

j par

Well-hung Member

Remember if you spend $221 on those frame connectors bahahaha don't forget to drill the holes real tight with close tolerances or else it'll just be pushing around in there.

j par

Well-hung Member

The truly one of the great things about having a non numbers matching slant 6 air condition car I can do whatever I want..

mderoy340

Well-Known Member

My home made frame connectors was the best mod I've done to my car regardless of drag racing or not. Stiffened the car up and took the body roll out of the car street driving.

No numbers on any of my cars that anyone would pay for.... LOLThe truly one of the great things about having a non numbers matching slant 6 air condition car I can do whatever I want..

I doubt I go the 220.00 dollar route.... I still haven't even decided what Duster I'm even going to use... LOL. But by digging through my junk, I did find the heads, intake, and cam that will be used. And I'm leaning towards my free Tri-Y's that somebody was going to throw away, and an old B-body 8 3/4 rear end I've had for years that somebody dumped off on a trade.. (why do my projects always end up like a Roadkill episode...Remember if you spend $221 on those frame connectors bahahaha don't forget to drill the holes real tight with close tolerances or else it'll just be pushing around in there.

.you should cut them and sell them here on FABO

He already wasted about eight sets building that snowmobile thing did I say snowmobile?

j par

Well-hung Member

I don't know why there's some big race to shorten rear ends and Tuck tires way underneath cars? I have ran an ebody width on my eighth and a quarter 8 and 3/4 and my Dana 60. A b body width would not even be but an extra inch. take that $220 and buy some cheap Summit headers and good gaskets for goodness sakes and stop trying to do a Roadkill episode every time...I doubt I go the 220.00 dollar route.... I still haven't even decided what Duster I'm even going to use... LOL. But by digging through my junk, I did find the heads, intake, and cam that will be used. And I'm leaning towards my free Tri-Y's that somebody was going to throw away, and an old B-body 8 3/4 rear end I've had for years that somebody dumped off on a trade.. (why do my projects always end up like a Roadkill episode...).

j par

Well-hung Member

Buy some aluminum heads and a 4-inch crank and get it over with!

Buy some aluminum heads and a 4-inch crank and get it over with!

yeah, blue print 2400 dollar stroker short block and some Chinese heads.

Wouldn't be easier and cheaper just to buy a 2000 dollar crotch rocket and go high 10's ??? I mean, if we're shooting for easy …...

Last edited:

-