63VALIANT*KISS

Well-Known Member

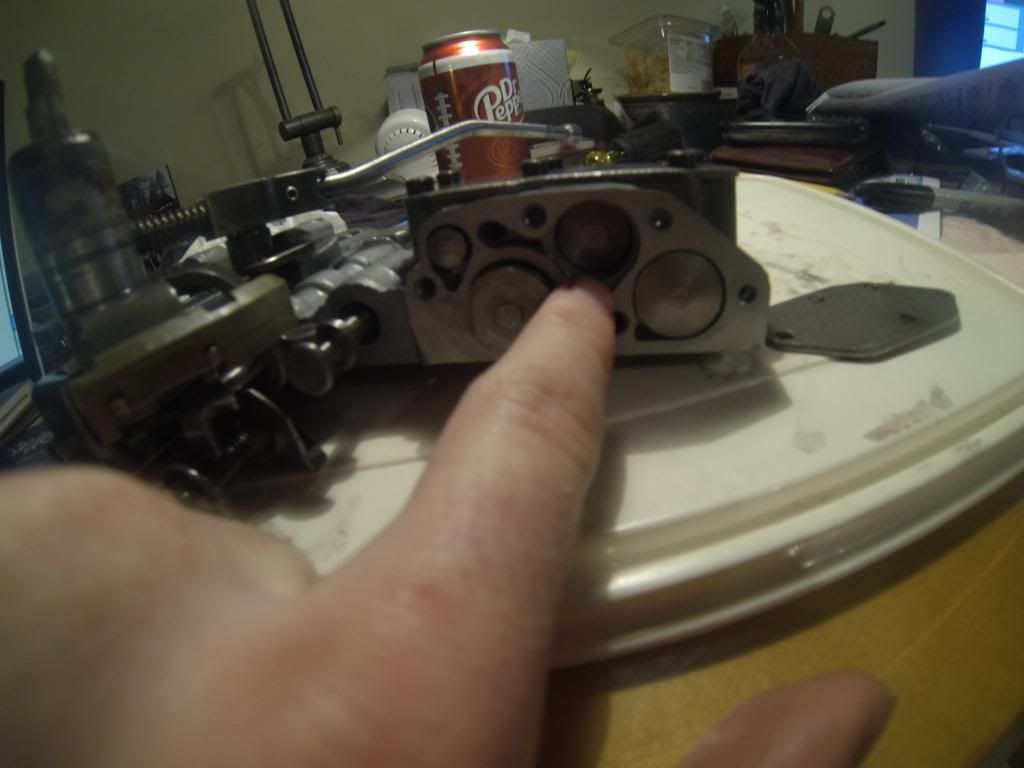

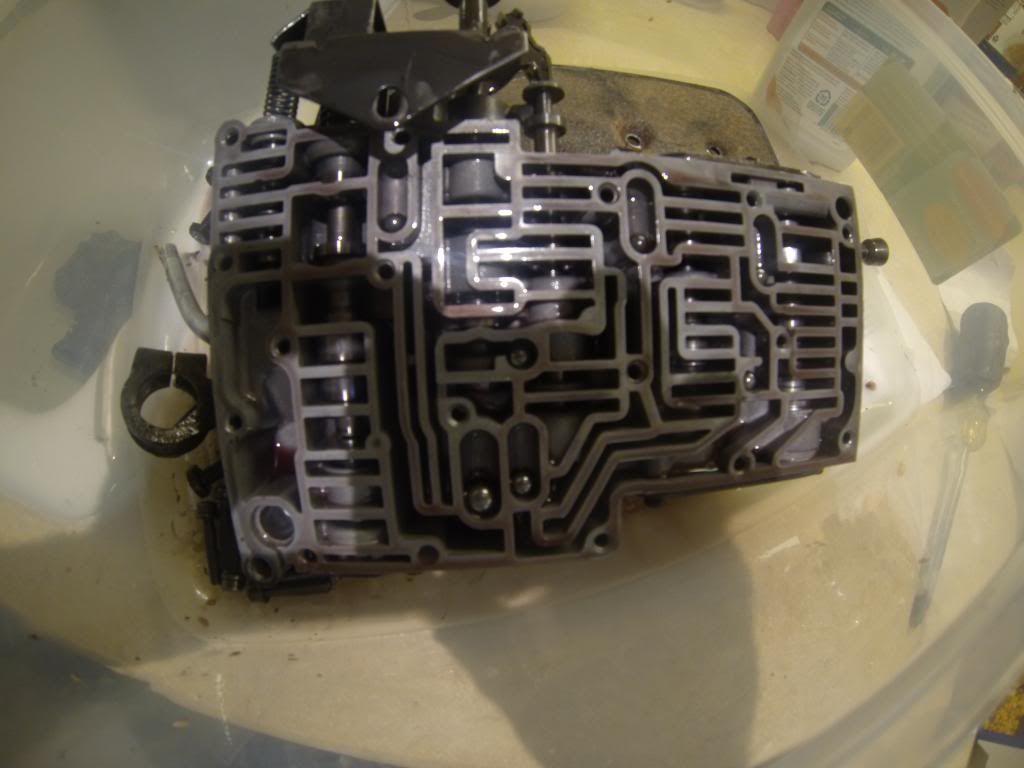

i love my b&m kit i beleive this is it on a stock trans with megashifter an po did tc so idk stall.shifts awesome not too hard not too wussy either i wish the aspen had this alrdy

http://www.summitracing.com/parts/bmm-10228/overview/

http://www.summitracing.com/parts/bmm-10228/overview/