Judge Mills

1971 Plymouth Duster

The Ranger axle will be just fine. You just won't have disc brakes. A bonus is that I believe both axle shafts are the same length, so I believe you don't have to shorten the axle.

I just got "tasked" to cut an 8.8 for a 68 Barracuda. I got 2 short axles and determined the long side needs exactly 3 inches sectioned out. I was going to take it from the inside part, right next to the center section and the vent tube fitting. Cut it, section it, Slip axle back in, C-clip it, use some L brackets and Vice grips to center the new length and tack and weld. He can worry about removing all the brackets. Offset is not a big issue, the driveshaft only needs to be on the same plane at the driveshaft slip yoke and the pinion angle, and that can be up or down 3-4 degrees depending on what power and rear suspension you have.

I cut 3 and I have about 1/8" of shiny axle on the end, before the center pin is installed. that tells me I cut it a little short, but since its a C clip, the bearings are about 1 inch wide and there seems to be a pretty wide bearing surface on the axle itself, exact is not necessary. I cut mine with a sawzall and then trued up the tube so I probably lost a few mm's. I feel I was close enough, but 2.875 would probably be closer to spec. You guys realize these weigh 170 lbs? How much does a practically sheetmetal 8 75 weigh?

I bought explorer rear a few months ago. Just did the cut down today. Went to pick and pull yesterday, got a short side axle. Saw another very clean 8.8 in a 99 model, 3L73. Pulled it out and another short axle from another 8.8. Paid 130.00 for rear complete and 2 extra axles including taxes and fee's.( I have a 54 chevy pick up its going into.)

Instead of a chop saw or sawzall to cut the axle tube, I used a pipe cutter on it. It tracked really well around the tube and left a straight cut. It also left a nice bevel also, made it very easy to weld. My pipe cutter wasn't big enough, so I went to the harbour frieght store and bought a #3 pipe cutter for 19.99. A ridged brand cutter will set you back about 300.00. This is one time the cheap tool really worked better. It has wide rollers, tracks straighter. You might want to check them out.

After I sanded the tube, measured and marked it, I had it cut really straight. I used a 4" piece of angle iron clamped to the tube and end to hold it in place when I tacked it. It worked well for me. just something you might want too consider if your going to do this mod.

Dave

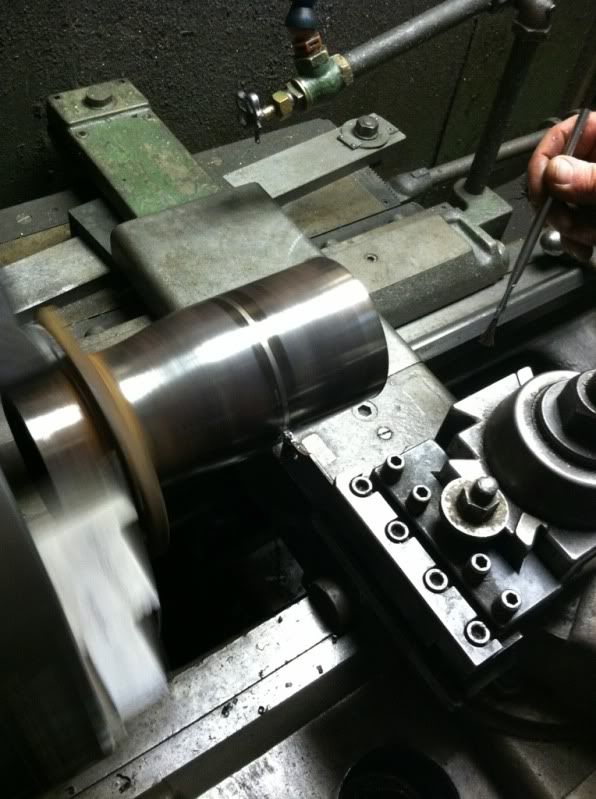

I am doing this swap as we speak. I got the explorer rearend with 4.10 gears and limited slip out of the junkyard for $250. I cut exactly 3" off the long side. Here are the pictures so far..

Way bigger axle tubes

That is coming out nice. Are you putting a slug in the tube or gonna butt weld? I am looking at using a lathe also, but for strength I am going to drill the plug welds, remove the axle tube from the center housing, cut it off/down on a lathe and slide the tube back in the housing, then re-plug weld and then weld the housing to the axle tubes. Am I overthinking this?

I'm going to weld the axle tubes after I'm all done. Even though the end is cut it should be just as strong as stock as long as the welding goes smooth ;) I will be using a tig welder. But your plan may give you some peace of mind especially if your going to in high Hp behind it.

I highly respected axle shop in Portland, OR just cut and welded the end of my 8.8. I was surprised they didn't drill out the plugs, but they said this is just fine. So, in other words, it should be just fine.